- Metallurgy

-

Metallurgy is a domain of materials science that studies the physical and chemical behavior of metallic elements, their intermetallic compounds, and their mixtures, which are called alloys. It is also the technology of metals: the way in which science is applied to their practical use. Metallurgy is distinguished from the craft of metalworking.

Contents

Etymology and pronunciation

The word was originally (1593) an alchemist's term for the extraction of metals from minerals: the ending -urgy signifying a process, especially manufacturing: it was in this sense it was used by the 1797 Encyclopaedia Britannica.[1] In the late 19th century it was extended to the more general scientific study of metals and alloys and related processes.[1] The roots are borrowed from Ancient Greek: μεταλλουργός, matallourgos, "worker in metal", from μέταλλον, metallon, "metal" + ἔργον, ergon, "work". In English, the /meˈtælədʒi/ pronunciation is the more common one in the UK and Commonwealth. The /ˈmetələrdʒi/ pronunciation is the more common one in the USA, and is the first-listed variant in various American dictionaries (e.g., Merriam-Webster Collegiate, American Heritage). Worldwide, both are accepted.

History

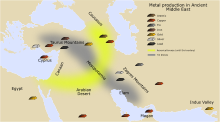

See also: Chalcolithic, Bronze Age, Iron Age, Metallurgy in Pre-Columbian America, Metallurgy in pre-Columbian Mesoamerica, and History of metallurgy in the Indian subcontinentThe first evidence of human metallurgy dates from the 5th and 6th millennium BC, and was found in the archaeological sites of Majdanpek, Yarmovac and Plocnik all three in Serbia. To date, the earliest copper smelting is found at the Belovode site,[2] these examples include a copper axe from 5,500BC belonging to the Vinča culture.[3] Other signs of human metallurgy are found from the third millennium BC in places like Palmela (Portugal), Cortes de Navarra (Spain), and Stonehenge (United Kingdom). However, as often happens with the study of prehistoric times, the ultimate beginnings cannot be clearly defined and new discoveries are continuous and ongoing.

Silver, copper, tin and meteoric iron can also be found native, allowing a limited amount of metalworking in early cultures. Egyptian weapons made from meteoric iron in about 3000 B.C. were highly prized as "Daggers from Heaven".[4] However, by learning to get copper and tin by heating rocks and combining those two metals to make an alloy called bronze, the technology of metallurgy began about 3500 B.C. with the Bronze Age.

The extraction of iron from its ore into a workable metal is much more difficult. It appears to have been invented by the Hittites in about 1200 B.C., beginning the Iron Age. The secret of extracting and working iron was a key factor in the success of the Philistines.[4][5]

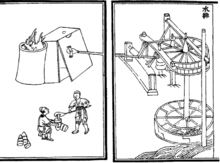

Historical developments in ferrous metallurgy can be found in a wide variety of past cultures and civilizations. This includes the ancient and medieval kingdoms and empires of the Middle East and Near East, ancient Iran, ancient Egypt, ancient Nubia, and Anatolia (Turkey), Ancient Nok, Carthage, the Greeks and Romans of ancient Europe, medieval Europe, ancient and medieval China, ancient and medieval India, ancient and medieval Japan, amongst others. Many applications, practices, and devices associated or involved in metallurgy were established in ancient China, such as the innovation of the blast furnace, cast iron, hydraulic-powered trip hammers, and double acting piston bellows.[6][7]

A 16th century book by Georg Agricola called De re metallica describes the highly developed and complex processes of mining metal ores, metal extraction and metallurgy of the time. Agricola has been described as the "father of metallurgy".[8]

Extraction

Extractive metallurgy is the practice of removing valuable metals from an ore and refining the extracted raw metals into a purer form. In order to convert a metal oxide or sulfide to a purer metal, the ore must be reduced physically, chemically, or electrolytically.

Extractive metallurgists are interested in three primary streams: feed, concentrate (valuable metal oxide/sulfide), and tailings (waste). After mining, large pieces of the ore feed are broken through crushing and/or grinding in order to obtain particles small enough where each particle is either mostly valuable or mostly waste. Concentrating the particles of value in a form supporting separation enables the desired metal to be removed from waste products.

Mining may not be necessary if the ore body and physical environment are conducive to leaching. Leaching dissolves minerals in an ore body and results in an enriched solution. The solution is collected and processed to extract valuable metals.

Ore bodies often contain more than one valuable metal. Tailings of a previous process may be used as a feed in another process to extract a secondary product from the original ore. Additionally, a concentrate may contain more than one valuable metal. That concentrate would then be processed to separate the valuable metals into individual constituents.

Alloys

Common engineering metals include aluminium, chromium, copper, iron, magnesium, nickel, titanium and zinc. These are most often used as alloys. Much effort has been placed on understanding the iron-carbon alloy system, which includes steels and cast irons. Plain carbon steels are used in low cost, high strength applications where weight and corrosion are not a problem. Cast irons, including ductile iron are also part of the iron-carbon system.

Stainless steel or galvanized steel are used where resistance to corrosion is important. Aluminium alloys and magnesium alloys are used for applications where strength and lightness are required.

Copper-nickel alloys (such as Monel) are used in highly corrosive environments and for non-magnetic applications. Nickel-based superalloys like Inconel are used in high temperature applications such as turbochargers, pressure vessel, and heat exchangers. For extremely high temperatures, single crystal alloys are used to minimize creep.

Production

In production engineering, metallurgy is concerned with the production of metallic components for use in consumer or engineering products. This involves the production of alloys, the shaping, the heat treatment and the surface treatment of the product. The task of the metallurgist is to achieve balance between material properties such as cost, weight, strength, toughness, hardness, corrosion, fatigue resistance, and performance in temperature extremes. To achieve this goal, the operating environment must be carefully considered. In a saltwater environment, ferrous metals and some aluminium alloys corrode quickly. Metals exposed to cold or cryogenic conditions may endure a ductile to brittle transition and lose their toughness, becoming more brittle and prone to cracking. Metals under continual cyclic loading can suffer from metal fatigue. Metals under constant stress at elevated temperatures can creep.

Metalworking processes

Metals are shaped by processes such as:

- casting - molten metal is poured into a shaped mould.

- forging - a red-hot billet is hammered into shape.

- flow forming

- rolling - a billet is passed through successively narrower rollers to create a sheet.

- Laser cladding - metallic powder is blown through a movable laser beam (e.g. mounted on a NC 5-axis machine). The resulting melted metal reach a substrate to from a melt pool. By moving the laser head, it is possible to stack the tracks and build up a 3D piece.

- extrusion - a hot and malleable metal is forced under pressure through a die, which shapes it before it cools.

- sintering - a powdered metal is heated in a non-oxidizing environment after being compressed into a die.

- metalworking

- machining - lathes, milling machines, and drills cut the cold metal to shape.

- fabrication - sheets of metal are cut with guillotines or gas cutters and bent into shape.

Cold working processes, where the product’s shape is altered by rolling, fabrication or other processes while the product is cold, can increase the strength of the product by a process called work hardening. Work hardening creates microscopic defects in the metal, which resist further changes of shape.

Various forms of casting exist in industry and academia. These include sand casting, investment casting (also called the “lost wax process”), die casting and continuous casting.

Heat treatment

Metals can be heat treated to alter the properties of strength, ductility, toughness, hardness or resistance to corrosion. Common heat treatment processes include annealing, precipitation strengthening, quenching, and tempering,[9]. The annealing process softens the metal by heating it and then allowing it to cool very slowly, which gets rid of stresses in the metal and makes the grain structure large and soft-edged so that when the metal is hit or stressed it dents or perhaps bends, rather than breaking; it is also easier to sand, grind, or cut annealed metal. Quenching is the process of cooling a high-carbon steel very quickly after you have heated it, thus "freezing" the steel's molecules in the very hard martensite form, which makes the metal harder. There is a balance between hardness and toughness in any steel, where the harder it is, the less tough or impact-resistant it is, and the more impact-resistant it is, the less hard it is. Tempering relieves stresses in the metal that were caused by the hardening process; tempering makes the metal less hard while making it better able to sustain impacts without breaking.

Often, mechanical and thermal treatments are combined in what is known as thermo-mechanical treatments for better properties and more efficient processing of materials. These processes are common to high alloy special steels, super alloys and titanium alloys.

Plating

Electroplating is a common surface-treatment technique. It involves bonding a thin layer of another metal such as gold, silver, chromium or zinc to the surface of the product. It is used to reduce corrosion as well as to improve the product's aesthetic appearance.

Thermal spraying

Thermal spraying techniques are another popular finishing option, and often have better high temperature properties than electroplated coatings.

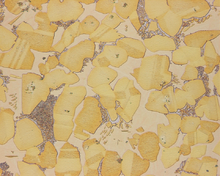

Microstructure

Metallurgists study the microscopic and macroscopic properties using metallography, a technique invented by Henry Clifton Sorby. In metallography, an alloy of interest is ground flat and polished to a mirror finish. The sample can then be etched to reveal the microstructure and macrostructure of the metal. The sample is then examined in an optical or electron microscope, and the image contrast provides details on the composition, mechanical properties, and processing history.

Crystallography, often using diffraction of x-rays or electrons, is another valuable tool available to the modern metallurgist. Crystallography allows identification of unknown materials and reveals the crystal structure of the sample. Quantitative crystallography can be used to calculate the amount of phases present as well as the degree of strain to which a sample has been subjected.

See also

- Metallurgical failure analysis

- Archaeometallurgy

- CALPHAD

- Carbonyl metallurgy

- Cupellation

- Georg Agricola

- Goldbeating

- Gold phosphine complex

- Mineral industry

- National Institute of Foundry and Forge Technology

- Pyrometallurgy

- Timeline of materials technology

- Experimental_Archaeometallurgy

References

- ^ a b Oxford English Dictionary, accessed 29 January 2011

- ^ doi:10.1016/j.jas.2010.06.012

- ^ Neolithic Vinca was a metallurgical culture Stonepages from news sources November 2007

- ^ a b W. Keller (1963) The Bible as History page 156 ISBN 0 340 00312 X

- ^ B. W. Anderson (1975) The Living World of the Old Testament page 154 ISBN 0-582-48598-3

- ^ R. F. Tylecote (1992) A History of Metallurgy ISBN 0-901462-88-8

- ^ Temple, Robert K.G. (2007). The Genius of China: 3,000 Years of Science, Discovery, and Invention (3rd edition). London: André Deutsch. pp. 44-56. ISBN 9780233002026.

- ^ Karl Alfred von Zittel (1901) History of Geology and Palaeontology page 15

- ^ Arthur Reardon (2011), Metallurgy for the Non-Metallurgist (2nd edition), ASM International, ISBN 978-1-61503-821-3

Categories:- Metals

- Metallurgy

- Numismatics

Wikimedia Foundation. 2010.