- Extractive metallurgy

-

Extractive metallurgy is the study of the processes used in the separation and concentration (benefaction) of raw materials. The field is an applied science, covering all aspects of the physical and chemical processes used to produce mineral-containing and metallic materials, sometimes for direct use as a finished product, but more often in a form that requires further physical processing which is generally the subject of physical metallurgy, ceramics, and other disciplines within the broad field of materials science.

The field of extractive metallurgy encompasses many specialty sub-disciplines, each concerned with various physical and chemical processes that are steps in an overall process of producing a particular material. These specialties are generically grouped into the categories of mineral processing, hydrometallurgy, pyrometallurgy, and electrometallurgy. The distinctions among these groups of sub-disciplines within extractive metallurgy is far from clear, and many commercially important metallurgical processes involve considerable overlap.

The theoretical basis of extractive metallurgy is underpinned by the more general sciences of physics, chemistry, and geology. Additionally, the practice of extractive metallurgy nearly always involves contributions from other scientific fields such as analytical chemistry and mineralogy.

Contents

Mineral processing

Mineral processing involves the processes used to manipulate the particle size of solid raw materials and to separate valuable materials from materials of no value, referred to as gangue. Usually, particle size reduction, also referred to as comminution, is required to permit efficient separation of the valuable materials from gangue. Separation processes take advantage of physical properties of the materials in order to separate them from each other. These physical properties can include density, particle size and shape, electrical and magnetic properties, and surface properties. Since many size reduction and separation processes involve the use of water, solid-liquid separation processes are also a subject of mineral processing.

Hydrometallurgy

Main article: HydrometallurgyHydrometallurgy is concerned with processes involving aqueous solutions to extract metals from ores. The most common hydrometallurgical process is leaching, which involves dissolution of the valuable metals into the aqueous solution. After the solution is separated from the ore solids, the solution is often subjected to various processes of purification and concentration before the valuable metal is recovered either in its metallic state or as a chemical compound. The solution purification and concentration processes may include precipitation, distillation, adsorption, and solvent extraction. The final recovery step may involve precipitation, cementation, or an electrometallurgical process. Sometimes, hydrometallurgical processes may be carried out directly on the ore material without any pretreatment steps. More often, the ore must be pretreated by various mineral processing steps, and sometimes by pyrometallurgical processes.

Pyrometallurgy

Main article: PyrometallurgyPyrometallurgy involves high temperature processes where chemical reactions take place among gases, solids, and molten materials. Solids containing valuable metals are reacted to form intermediate compounds for further processing or converted into their elemental or metallic state. Pyrometallurgical processes that involve gases and solids are typified by calcining and roasting operations. Processes that produce molten products are collectively referred to as smelting operations. The energy required to sustain the high temperature pyrometallurgical processes may come entirely from the exothermic nature of the chemical reactions taking place, usually oxidation reactions. Often, however, energy must be added to the process by combustion of fuel or, in the case of some smelting processes, by the direct application of electrical energy.

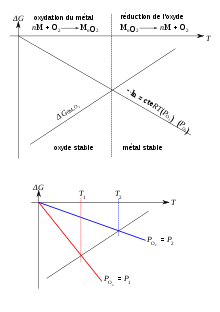

Ellingham Diagrams are a useful way of analysing the possible reactions, and so predicting their outcome.

Electrometallurgy

Main article: ElectrometallurgyElectrometallurgy involves metallurgical processes that take place in some form of electrolytic cell. The most common types of electrometallurgical processes are electrowinning and electro-refining. Electrowinning is an electrolysis process used to recover metals in aqueous solution, usually as the result of an ore having undergone one or more hydrometallurgical processes. The metal of interest is plated onto the cathode, while the anode is an inert electrical conductor. Electro-refining is used to dissolve an impure metallic anode (typically from a smelting process) and produce a high purity cathode. Fused salt electrolysis is another electrometallurgical process whereby the valuable metal has been dissolved into a molten salt which acts as the electrolyte, and the valuable metal collects on the cathode of the cell. The fused salt electrolysis process is conducted at temperatures sufficient to keep both the electrolyte and the metal being produced in the molten state. The scope of electrometallurgy has significant overlap with the areas of hydrometallurgy and (in the case of fused salt electrolysis) pyrometallurgy. Additionally, electrochemical phenomena play a considerable role in many mineral processing and hydrometallurgical processes.

References

Gilchrist, J.D. (1989). "Extraction Metallurgy", Pergamon Press.

Categories:

Wikimedia Foundation. 2010.