- Diesel cycle

-

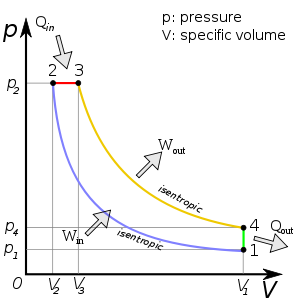

The Diesel cycle is the thermodynamic cycle which approximates the pressure and volume of the combustion chamber of the Diesel engine, invented by Rudolph Diesel in 1897. It is assumed to have constant pressure during the first part of the "combustion" phase (V2 to V3 in the diagram, below). This is an idealized mathematical model: real physical Diesels do have an increase in pressure during this period, but it is less pronounced than in the Otto cycle. The idealized Otto cycle of a gasoline engine approximates constant volume during that phase, generating more of a spike in a p-V diagram.

Contents

The Idealized Diesel Cycle

The image on the left shows a p-V diagram for the ideal Diesel cycle; where p is pressure and v is specific volume. The ideal Diesel cycle follows the following four distinct processes (The color references refer to the color of the line on the diagram.):

- Process 1 to 2 is isentropic compression of the fluid(blue colour)

- Process 2 to 3 is reversible constant pressure heating (red)

- Process 3 to 4 is isentropic expansion (yellow)

- Process 4 to 1 is reversible constant volume cooling (green)[1]

The Diesel is a heat engine: it converts heat into work. The isentropic processes are impermeable to heat: heat flows into the loop through the left expanding isobaric process and some of it flows back out through the right depressurizing process, and the heat that remains does the work.

- Work in (Win) is done by the piston compressing the working fluid

- Heat in (Qin) is done by the combustion of the fuel

- Work out (Wout) is done by the working fluid expanding on to the piston (this produces usable torque)

- Heat out (Qout) is done by venting the air

Maximum thermal efficiency

The maximum thermal efficiency of a Diesel cycle is dependent on the compression ratio and the cut-off ratio. It has the following formula under cold air standard analysis:

where

- ηth is thermal efficiency

- α is the cut-off ratio

(ratio between the end and start volume for the combustion phase)

(ratio between the end and start volume for the combustion phase) - r is the compression ratio

- γ is ratio of specific heats (Cp/Cv)[2]

The cut-off ratio can be expressed in terms of temperature as shown below:

T3 can be approximated to the flame temperature of the fuel used. The flame temperature can be approximated to the adiabatic flame temperature of the fuel with corresponding air-to-fuel ratio and compression pressure, p3. T1 can be approximated to the inlet air temperature.

This formula only gives the ideal thermal efficiency. The actual thermal efficiency will be significantly lower due to heat and friction losses. The formula is more complex than the Otto cycle (petrol/gasoline engine) relation that has the following formula;

The additional complexity for the Diesel formula comes around since the heat addition is at constant pressure and the heat rejection is at constant volume. The Otto cycle by comparison has both the heat addition and rejection at constant volume.

Comparing the two formulae it can be seen that for a given compression ratio (r), the ideal Otto cycle will be more efficient. However, a Diesel engine will be more efficient overall since it will have the ability to operate at higher compression ratios. If a petrol engine were to have the same compression ratio, then knocking (self-ignition) would occur and this would severely reduce the efficiency, whereas in a Diesel engine, the self ignition is the desired behavior. Additionally, both of these cycles are only idealizations, and the actual behavior does not divide as clearly or sharply. And the ideal Otto cycle formula stated above does not include throttling losses, which do not apply to Diesel engines.

The Diesel cycle is a combustion process of a reciprocating internal combustion engine. In it, fuel is ignited by heat generated by compressing air in the combustion chamber, into which fuel is injected. This is in contrast to igniting it with a spark plug as in the Otto cycle (four-stroke/petrol) engine. Diesel engines (heat engines using the Diesel cycle) are used in automobiles, power generation, Diesel-electric locomotives, and submarines.

Applications

Diesel engines

Main article: Diesel engineThe Diesel engine has the lowest specific fuel consumption of any large internal combustion engine, 0.26 lb/hp.h (0.16 kg/kWh) for very large marine engines. Two-stroke Diesels with high pressure forced induction, particularly turbocharging, make up a large percentage of the very largest Diesel engines.

In North America, Diesel engines are primarily used in large trucks, where the low-stress, high-efficiency cycle leads to much longer engine life and lower operational costs. These advantages also make the Diesel engine ideal for use in the heavy-haul railroad environment.

Other internal combustion engines without spark plugs

Many model airplanes use very simple "glow" and "Diesel" engines. Glow engines use glow plugs. "Diesel" model airplane engines have variable compression ratios. Both types depend on special fuels (easily obtainable in such limited quantities) for their ignition timing.

Some 19th century or earlier experimental engines used external flames, exposed by valves, for ignition, but this becomes less attractive with increasing compression. (It was the research of Nicolas Léonard Sadi Carnot that established the thermodynamic value of compression.) A historical implication of this is that the Diesel engine would eventually have been invented without the aid of electricity.

See the development of the hot bulb engine and indirect injection for historical significance.References

- ^ Eastop & McConkey 1993, Applied Thermodynamics for Engineering Technologists, Pearson Education Limited, Fifth Edition, p.137

- ^ The Diesel Engine

See also

Thermodynamic cycles External combustion cycles Bell Coleman · Brayton/Joule (externally heated) · Carnot · Ericsson · Ported constant volume[1] · Stirling · Stirling (Pseudo / Adiabatic) · StoddardWith phase changeInternal combustion cycles Atkinson · Brayton/Joule · Diesel · Expander · Gas-generator · Homogeneous Charge Compression Ignition · Lenoir · Miller · Otto · Pressure-fed · Staged combustionMixed cycles Refrigeration cycles Hampson-Linde · Kleemenko · Linde dual-pressure · Pulse tube · Regenerative cooling · Transcritical · Vapor absorption · Vapor-compression · Siemens · VuilleumierUncategorized Categories:- Thermodynamic cycles

Wikimedia Foundation. 2010.