- Brayton cycle

-

The Brayton cycle is a thermodynamic cycle that describes the workings of the gas turbine engine, basis of the airbreathing jet engine and others. It is named after George Brayton (1830–1892), the American engineer who developed it, although it was originally proposed and patented by Englishman John Barber in 1791.[1] It is also sometimes known as the Joule cycle. The Ericsson cycle is similar but uses external heat and incorporates the use of a regenerator.

Contents

History

In 1872, George Brayton applied for a patent for his Ready Motor. The engine used a separate piston compressor and expander. The compressed air was heated by internal fire as it entered the expander cylinder. Brayton produced and sold "Ready Motors" to perform a variety of tasks like water pumping, mill operation, even marine propulsion.

Critics of the day claimed the engines ran smoothly and had an efficiency of about 17%.

Today the term Brayton cycle is generally associated with the gas turbine, even though Brayton only built piston engines.

The Brayton cycle is a cycle which can be used in both internal combustion engines (such as jet engines) and for external combustion engines.

Although the Brayton cycle is usually run as an open system (and indeed must be run as such if internal combustion is used), it is conventionally assumed for the purposes of thermodynamic analysis that the exhaust gases are reused in the intake, enabling analysis as a closed system.

Another interesting piece of Brayton cycle history was its use in the Selden patent. In the early days of the automobile, a creative attorney "Selden" claimed to have a patent for the internal combustion powered version. The patent drawings showed the use of Brayton cycle engine. Instead of paying royalties, Henry Ford fought the Selden patent. Ford argued his cars used the four-stroke Otto cycle and not the Brayton engine shown used in the Selden auto. Ford won the case.

Model

A Brayton-type engine consists of three components:

- A gas compressor

- A mixing chamber

- An expander

In the original 19th-century Brayton engine, ambient air is drawn into a piston compressor, where it is compressed; ideally an isentropic process. The compressed air then runs through a mixing chamber where fuel is added, an isobaric process. The heated (by compression), pressurized air and fuel mixture is then ignited in an expansion cylinder and energy is released, causing the heated air and combustion products to expand through a piston/cylinder; another ideally isentropic process. Some of the work extracted by the piston/cylinder is used to drive the compressor through a crankshaft arrangement.

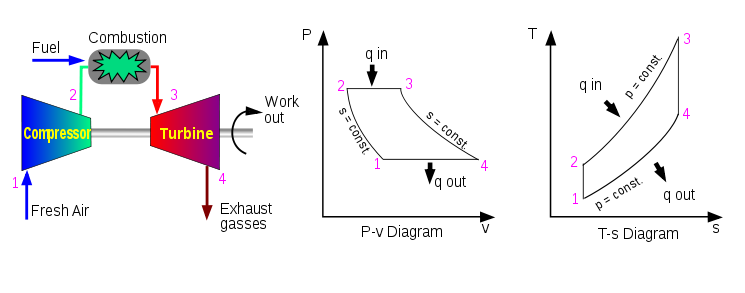

The term Brayton cycle has more recently been given to the gas turbine engine. This also has three components:

- A gas compressor

- A burner (or combustion chamber)

- An expansion turbine

Ideal Brayton cycle:

- isentropic process - Ambient air is drawn into the compressor, where it is pressurized.

- isobaric process - The compressed air then runs through a combustion chamber, where fuel is burned, heating that air—a constant-pressure process, since the chamber is open to flow in and out.

- isentropic process - The heated, pressurized air then gives up its energy, expanding through a turbine (or series of turbines). Some of the work extracted by the turbine is used to drive the compressor.

- isobaric process - Heat rejection (in the atmosphere).

Actual Brayton cycle:

- adiabatic process - Compression.

- isobaric process - Heat addition.

- adiabatic process - Expansion.

- isobaric process - Heat rejection.

Since neither the compression nor the expansion can be truly isentropic, losses through the compressor and the expander represent sources of inescapable working inefficiencies. In general, increasing the compression ratio is the most direct way to increase the overall power output of a Brayton system.[2]

The efficiency of the ideal Brayton cycle is

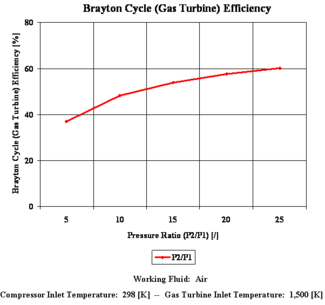

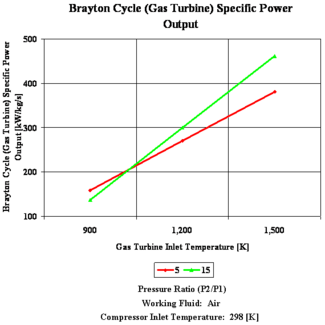

, where γ is the heat capacity ratio.[3] Figure 1 indicates how the cycle efficiency changes with an increase in pressure ratio. Figure 2 indicates how the specific power output changes with an increase in the gas turbine inlet temperature for two different pressure ratio values.

, where γ is the heat capacity ratio.[3] Figure 1 indicates how the cycle efficiency changes with an increase in pressure ratio. Figure 2 indicates how the specific power output changes with an increase in the gas turbine inlet temperature for two different pressure ratio values.In 2002 a hybrid open solar Brayton cycle was operated for the first time consistently and effectively with relevant papers published, in the frame of the EU SOLGATE program.[4] The air was heated from 570 K to over 1000 K into the combustor chamber. Further hybridization was achieved during the EU Solhyco project running a hybridized Brayton cycle with solar energy and Biodiesel only.[5]

Methods to increase power

The power output of a Brayton engine can be improved in the following manners:

- Reheat, wherein the working fluid—in most cases air—expands through a series of turbines, then is passed through a second combustion chamber before expanding to ambient pressure through a final set of turbines. This has the advantage of increasing the power output possible for a given compression ratio without exceeding any metallurgical constraints (typically about 1000 °C). The use of an afterburner for jet aircraft engines can also be referred to as "reheat"; it is a different process in that the reheated air is expanded through a thrust nozzle rather than a turbine. The metallurgical constraints are somewhat alleviated, enabling much higher reheat temperatures (about 2000 °C). Reheat is most often used to improve the specific power (per throughput of air), and is usually associated with a reduction in efficiency; this is most pronounced with the use of afterburners due to the extreme amounts of extra fuel used.

- Overspray, wherein, after a first compressor stage, water is injected into the compressor, thus increasing the mass-flow inside the compressor, increasing the turbine output power significantly and reducing compressor outlet temperatures.[6] In a second compressor stage the water gets completely evaporated.

Methods to improve efficiency

The efficiency of a Brayton engine can be improved in the following manners:

- Increasing pressure ratio - As Figure 1 above shows, increasing the pressure ratio increases the efficiency of the Brayton cycle. This is analogous to the increase of efficiency seen in the Otto cycle when the compression ratio is increased. However, there are practical limits when it comes to increasing the pressure ratio. First of all, increasing the pressure ratio increases the compressor discharge temperature. This can cause the temperature of the gasses leaving the combustor to exceed the metallurgical limits of the turbine. Also, the diameter of the compressor blades becomes progressively smaller in higher pressure stages of the compressor. Because the gap between the blades and the engine casing increases in size as a percentage of the compressor blade height as the blades get smaller in diameter, a greater percentage of the compressed air can leak back past the blades in higher pressure stages. This causes a drop in compressor efficiency, and is most likely to occur in smaller gas turbines (since blades are inherently smaller to begin with). Finally, as can be seen in Figure 1, the efficiency levels off as pressure ratio increases. Hence, there is little to gain by increasing the pressure ratio further if it is already at a high level.

- Regeneration, wherein the still-warm post-turbine fluid is passed through a heat exchanger to preheat the fluid just entering the combustion chamber. This directly offsets fuel consumption for the same operating conditions, improving efficiency; it also results in less power lost as waste heat. However, at higher pressure ratios, the compressor discharge temperature can exceed the exhaust temperature. Under these conditions, regeneration would be counterproductive. Therefore, regeneration is only an option when the pressure ratio is sufficiently low that the exhaust temperature is higher than the compressor discharge temperature.

This feature is only available if the exhaust heat is not used otherwise, as in cogeneration or combined cycle applications.

- A Brayton engine also forms half of the combined cycle system, which combines with a Rankine engine to further increase overall efficiency. However, although this increases overall efficiency, it does not actually increase the efficiency of the Brayton cycle itself.

- Cogeneration systems make use of the waste heat from Brayton engines, typically for hot water production or space heating.

Reverse Brayton cycle

A Brayton cycle that is driven in reverse, via net work input, and when air is the working fluid, is the air refrigeration cycle or Bell Coleman cycle. Its purpose is to move heat, rather than produce work. This air cooling technique is used widely in jet aircraft.

See also

- Gas turbine

- Jet engine

- Heat engines

- Thermodynamics

- Power

- HVAC

- Engineering

- Gerotor

References

- ^ according to Gas Turbine History

- ^ Lester C. Lichty, Combustion Engine Processes, 1967, McGraw-Hill, Inc., Lib.of Congress 67-10876

- ^ http://web.mit.edu/16.unified/www/SPRING/propulsion/notes/node27.html Ideal cycle equations, MIT lecture notes

- ^ http://ec.europa.eu/research/energy/pdf/solgate_en.pdf

- ^ www.solhyco.com

- ^ http://www.max-boost.co.uk/max-boost/resources/docs/SwirlFlash_WI.pdf

External links

- Today in Science article on Brayton Engine

- http://scitation.aip.org/getabs/servlet/GetabsServlet?prog=normal&id=JSEEDO000126000003000872000001&idtype=cvips&gifs=yes

- http://elib.dlr.de/46328/

- http://www.sciencedirect.com/science?_ob=ArticleURL&_udi=B6V50-4GP6WDN-1&_user=10&_coverDate=10%2F31%2F2006&_rdoc=1&_fmt=&_orig=search&_sort=d&view=c&_acct=C000050221&_version=1&_urlVersion=0&_userid=10&md5=b7c7869ea69813a7397758263df4667c

Thermodynamic cycles External combustion cycles Bell Coleman · Brayton/Joule (externally heated) · Carnot · Ericsson · Ported constant volume[1] · Stirling · Stirling (Pseudo / Adiabatic) · StoddardInternal combustion cycles Atkinson · Brayton/Joule · Diesel · Expander · Gas-generator · Homogeneous Charge Compression Ignition · Lenoir · Miller · Otto · Pressure-fed · Staged combustionMixed cycles Refrigeration cycles Hampson-Linde · Kleemenko · Linde dual-pressure · Pulse tube · Regenerative cooling · Transcritical · Vapor absorption · Vapor-compression · Siemens · VuilleumierUncategorized Categories:- Thermodynamic cycles

Wikimedia Foundation. 2010.