- Atkinson cycle

-

The Atkinson cycle engine is a type of internal combustion engine invented by James Atkinson in 1882. The Atkinson cycle is designed to provide efficiency at the expense of power density, and is used in some modern hybrid electric applications.

Contents

Design

The original Atkinson cycle piston engine allowed the intake, compression, power, and exhaust strokes of the four-stroke cycle to occur in a single turn of the crankshaft and was designed to avoid infringing certain patents covering Otto cycle engines.[1] Due to the unique crankshaft design of the Atkinson, its expansion ratio can differ from its compression ratio and, with a power stroke longer than its compression stroke, the engine can achieve greater thermal efficiency than a traditional piston engine. While Atkinson's original design is no more than an historical curiosity, many modern engines use unconventional valve timing to produce the effect of a shorter compression stroke/longer power stroke, thus realizing the fuel economy improvements the Atkinson cycle can provide.[2]

Ideal thermodynamic cycle

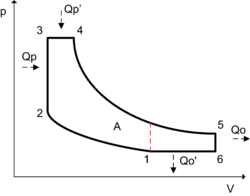

The ideal Atkinson cycle consists of following operations:

- 1-2 Isentropic or reversible adiabatic compression

- 2-3 Isochoric heating (Qp)

- 3-4 Isobaric heating (Qp')

- 4-5 Isentropic expansion

- 5-6 Isochoric cooling (Qo)

- 6-1 Isobaric cooling (Qo')

Modern Atkinson cycle engines

Recently Atkinson cycle has been used to describe a modified Otto cycle engine in which the intake valve is held open longer than normal to allow a reverse flow of intake air into the intake manifold. The effective compression ratio is reduced (for a time the air is escaping the cylinder freely rather than being compressed) but the expansion ratio is unchanged. This means the compression ratio is smaller than the expansion ratio. Heat gained from burning fuel increases the pressure, thereby forcing the piston to move, expanding the air volume beyond the volume when compression began. The goal of the modern Atkinson cycle is to allow the pressure in the combustion chamber at the end of the power stroke to be equal to atmospheric pressure; when this occurs, all the available energy has been obtained from the combustion process. For any given portion of air, the greater expansion ratio allows more energy to be converted from heat to useful mechanical energy meaning the engine is more efficient.

The disadvantage of the four-stroke Atkinson cycle engine versus the more common Otto cycle engine is reduced power density. Due to a smaller portion of the compression stroke being devoted to compressing the intake air, an Atkinson cycle engine does not take in as much air as would a similarly designed and sized Otto cycle engine.

Four-stroke engines of this type with this same type of intake valve motion but with a supercharger to make up for the loss of power density are known as Miller cycle engines.

Rotary Atkinson cycle engine

Rotary Atkinson cycle engine

Rotary Atkinson cycle engineThe Atkinson cycle can be used in a rotary engine. In this configuration an increase in both power and efficiency can be achieved when compared to the Otto cycle. This type of engine retains the one power phase per revolution, together with the different compression and expansion volumes of the original Atkinson cycle. Exhaust gases are expelled from the engine by compressed-air scavenging. This modification of the Atkinson cycle allows for the use of alternative fuels like diesel and hydrogen. Disadvantages of this design include the requirement that rotor tips seal very tightly on the outer housing wall and the mechanical losses suffered through friction between rapidly oscillating parts of irregular shape. See External Links for more information.

Vehicles using Atkinson cycle engines

2004 Toyota Prius hybrid

2009 Ford Fusion Hybrid, as sold in the United States. Unrelated to the European car of the same name.

2009 Ford Fusion Hybrid, as sold in the United States. Unrelated to the European car of the same name.

While a modified Otto cycle engine using the Atkinson cycle provides good fuel economy, it is at the expense of a lower power-per-displacement as compared to a traditional four-stroke engine.[3] If demand for more power is intermittent, the power of the engine can be supplemented by an electric motor during times when more power is needed. This forms the basis of an Atkinson cycle-based hybrid electric drivetrain. These electric motors can be used independently of, or in combination with, the Atkinson cycle engine, to provide the most efficient means of producing the desired power.

Several production vehicles use Atkinson cycle engines:

- Chevrolet Tahoe Hybrid electric (four-wheel drive) with a compression ratio of 10.8:1

- Ford Escape/Mercury Mariner/Mazda Tribute electric (front- and four-wheel drive) with a compression ratio of 12.4:1

- Ford Fusion Hybrid/Mercury Milan Hybrid/Lincoln MKZ Hybrid electric (front-wheel drive) with a compression ratio of 12.3:1

- Hyundai Sonata Hybrid (front-wheel drive)

- Infiniti M35h Hybrid (rear-wheel drive)

- Kia Optima Hybrid (front-wheel drive)

- Lexus CT200H (front-wheel drive)

- Lexus HS250h (front-wheel drive)

- Lexus RX 450h hybrid electric (front-wheel drive)

- Mercedes ML450 Hybrid (four-wheel drive) electric

- Mercedes S400 Blue Hybrid (rear-wheel drive) electric

- Toyota Highlander Hybrid (2011 and newer)[4]

- Toyota Prius hybrid electric (front-wheel drive) with a (purely geometric) compression ratio of 13.0:1

- Toyota Camry Hybrid electric (front-wheel drive) with a compression ratio of 12.5:1

- Lexus GS450h hybrid electric (Rear-Wheel drive) with a compression ratio of 13.0:1

See also

References

- ^ U.S. Patent 367,496

- ^ http://www.canadiandriver.com/2010/07/14/auto-tech-atkinson-cycle-engines-and-hybrids.htm

- ^ Heywood, John B. Internal Combustion Engine Fundamentals, pp. 184-186.

- ^ http://www.edmunds.com/toyota/highlander-hybrid/2011/road-test.html

External links

- Animation of Atkinson Cycle Engine Note that this animation shows the true Atkinson engine, which uses a complex linkage that allows different stroke lengths for intake/compression and power/exhaust. However, the illustration shows the engine with the linkage laid out to generate 4 equal strokes. To alter the ratio of the strokes, the rightmost pivot point (the one that is attaching the horizontal green link to the frame) should be moved downwards along the frame. This will allow more angular movement as the link rotates up, giving a longer piston stroke for power and exhaust, and less angular movement as the link rotates down, giving a shorter piston stroke for intake and compression. In fact, a sliding pivot point at that location would allow the engine to dynamically change the stroke ratios.

- Modified Atkinson Cycle Engine: Alternative variable valve timing strategy increases low speed torque obtainable from Atkinson Cycle Engine.

- Comparison of Prime Movers Suitable for USMC Expeditionary Power Sources, Oak Ridge National Laboratory

- Libralato Engines - developing a rotary Atkinson cycle engine

- Rotary Atkinson cycle engine - gives details of this engine as well as comparisons with conventional and Wankel engines

- The Prius's Not So Secret Gas-Mileage Secrets - how the Prius uses the Atkinson cycle to get better results than an Otto cycle engine

Thermodynamic cycles External combustion cycles Bell Coleman · Brayton/Joule (externally heated) · Carnot · Ericsson · Ported constant volume[1] · Stirling · Stirling (Pseudo / Adiabatic) · StoddardWith phase changeInternal combustion cycles Atkinson · Brayton/Joule · Diesel · Expander · Gas-generator · Homogeneous Charge Compression Ignition · Lenoir · Miller · Otto · Pressure-fed · Staged combustionMixed cycles Refrigeration cycles Hampson-Linde · Kleemenko · Linde dual-pressure · Pulse tube · Regenerative cooling · Transcritical · Vapor absorption · Vapor-compression · Siemens · VuilleumierUncategorized Categories:- Thermodynamic cycles

- Hybrid vehicles

Wikimedia Foundation. 2010.