- Counterbore

-

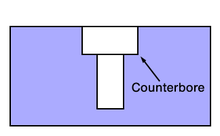

A counterbore can refer to a cylindrical flat-bottomed hole, which enlarges another hole, or the tool used to create that feature. A spot face is a very shallow counterbore. A counterbore hole is used when a fastener is required to sit flush with or below the level of a workpiece's surface.

Contents

Description

A counterbore hole is usually used when a fastener such as a bolt or cap head screw is required to sit flush with or below the level of a workpiece's surface.

For a spot face, material is removed from a surface to make it flat and smooth, usually for a fastener or a bearing. It is usually required on workpieces that are forged or cast. A counterbore is typically used to cut the spot face, although endmills are also used. Only enough material is removed to make the surface flat.[1]

A counterbore hole it is also used to create a perpendicular surface on a non-perpendicular surface for a fastener. If this is not feasible then a self-aligning nut may be required.

By comparison, a countersink makes a conical hole and is used to seat a flathead screw.

Machining

Counterbores are usually made with standard dimensions for a certain size of screw. The tip of the tool is called the pilot. Assuming the first, smaller-diameter hole has been drilled to the standard diameter for the particular screw size, the pilot will fit the hole with little clearance and will help to provide rigidity and hole center location (i.e., centerfinding). This is extremely helpful when running the cutter with a pistol-grip drill (to keep the tool from wandering) and on a drill press (for fast, easy return to coaxiality with the original hole center). The pilot matters little when running the cutter in a milling setup where rigidity is assured and hole center location is already achieved via X-Y positioning.

The uppermost counterbore tools shown in the image are the same device. The smaller top item is an insert, the middle shows another three-fluted counterbore insert, assembled in the holder. The shank of this holder is a morse taper although there are other machine tapers that are used in the industry. The lower counterbore is designed to fit into drill chuck, and being smaller, is economical to make as one piece.

See also

References

Notes

- ^ Degarmo, Black & Kohser 2003, p. 606.

Bibliography

- Degarmo, E. Paul; Black, J T.; Kohser, Ronald A. (2003), Materials and Processes in Manufacturing (9th ed.), Wiley, ISBN 0-471-65653-4.

Categories:- Machining

- Metalworking cutting tools

- Metalworking terminology

Wikimedia Foundation. 2010.