- Nickel–iron battery

-

Nickel–iron battery specific energy 30[1] −50[2] Wh/kg energy density 30[1] Wh/l specific power 100[2] W/kg Charge/discharge efficiency 65%–80%[3] Energy/consumer-price 1.5[1] – 6.6[2] Wh/US$ Self-discharge rate 20%[1][2] – 30%[2]/month Time durability 30[3] – 50 years[1][4] Cycle durability Repeated deep discharge does not reduce life significantly.[1][3] Nominal cell voltage 1.2 V[2] Charge temperature interval min. −40 °C – max.46 °C[5] The nickel–iron battery (NiFe battery) is a storage battery having a nickel(III) oxide-hydroxide cathode and an iron anode, with an electrolyte of potassium hydroxide. The active materials are held in nickel-plated steel tubes or perforated pockets. It is a very robust battery which is tolerant of abuse, (overcharge, overdischarge, and short-circuiting) and can have very long life even if so treated.[6] It is often used in backup situations where it can be continuously charged and can last for more than 20 years. Due to its low specific energy, poor charge retention, and its high cost of manufacture, other types of rechargeable batteries have displaced the nickel–iron battery in most applications.[7]

They are currently gaining popularity for off-the-grid applications where daily charging makes them an appropriate technology.[citation needed]

Contents

Durability

The ability of these batteries to survive frequent cycling is due to the low solubility of the reactants in the electrolyte. The formation of metallic iron during charge is slow because of the low solubility of the ferrous hydroxide. While the slow formation of iron crystals preserves the electrodes, it also limits the high rate performance: these cells charge slowly, and are only able to discharge slowly.[6] Nickel–iron cells should not be charged from a constant voltage supply since they can be damaged by thermal runaway; the cell internal voltage drops as gassing begins, raising temperature, which increases current drawn and so further increases gassing and temperature.

Nickel-iron batteries have long been used in European mining operations because of their ability to withstand vibrations, high temperatures and other physical stress. They are being examined again for use in wind and solar power systems and for modern electric vehicles, especially boats, where the weight of the batteries is not an issue.

Electrochemistry

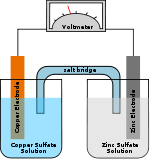

The half-cell reaction at the cathode:

- 2 NiOOH + 2 H2O + 2 e− ↔ 2 Ni(OH)2 + 2 OH−

and at the anode:

- Fe + 2 OH− ↔ Fe(OH)2 + 2 e−

(Discharging is read left to right, charging is from right to left.)[8]

The open-circuit voltage is 1.4 volts, dropping to 1.2 volts during discharge.[6] The electrolyte mixture of potassium hydroxide and lithium hydroxide is not consumed in charging or discharging, so unlike a lead-acid battery the electrolyte specific gravity does not indicate state of charge.[6] Lithium hydroxide improves the performance of the cell. the voltage required to charge the cells is between 1.45 and 1.65 volts. The equalization charge voltage is 1.65 volts.

History

Swedish inventor Waldemar Jungner had invented the nickel–cadmium battery in 1899. Jungner experimented with substituting iron for the cadmium in varying proportions, including 100% iron. Jungner had already discovered that the main advantage over the nickel–cadmium chemistry was cost, but due to the lower efficiency of the charging reaction and more pronounced formation of hydrogen (gassing), the nickel–iron technology was found wanting and abandoned. Jungner had several patents for the iron version of his battery (Swedesh pat.Nos 8.558/1897, 10.177/1899, 11.132/1899, 11.487/1899 and German Patent No.110.210 /1899. Moreover he had one patent for NiCd battery: Swed.pat No. 15.567/1899.[9]

The battery was developed by Thomas Edison in 1901, and used as the energy source for electric vehicles, such as the Detroit Electric and Baker Electric. Edison claimed the nickel–iron design to be, "far superior to batteries using lead plates and acid" (lead–acid battery). Edison had also several patents: US.Pat No.678.722/1901, 692.507/1902 and German patent No 157.290/1901.[9]

Jungner's work was largely unknown in the US until the 1940s, when nickel-cadmium batteries went into production there. A 50 volt nickel–iron battery was the main power supply in the World War II German V2 rocket (together with two 16 volt accumulators which powered the four gyroscopes), with a smaller version used in the V1 flying bomb. (viz. 1946 Operation Backfire blueprints.)

Manufacture

Edison's batteries were made from about 1903 to 1972 by the Edison Storage Battery Company in East Orange, NJ. They were quite profitable for the company. In 1972 the battery company was sold to the Exide Battery Corporation, which discontinued making the battery in 1975.

Edison was disappointed that his battery was not adopted for starting internal combustion engines and that electric vehicles went out of production only a few years after his battery was introduced. He actually developed the battery to be the battery of choice for electric vehicles which were the preferred transportation mode in the early 1900s (followed by gasoline and steam). Edison's batteries had a significantly higher energy density than the lead–acid batteries in use at the time, and could be charged in half the time, however they performed poorly at low ambient temperatures and were more expensive. The battery enjoyed wide use for railroad signaling, fork lift, and standby power applications.

Nickel–iron cells were made with capacities from 5 to 1250 Ah. Many of the original manufacturers no longer make nickel iron cells.[6] Currently they are being manufactured in China and Russia as well as in the US.

Environmental impact

Nickel–iron batteries do not have the lead or cadmium of the lead–acid and nickel–cadmium batteries, which makes them a lesser burden on human and ecological health.

See also

References

- ^ a b c d e f A description of the Chinese nickel–iron battery from BeUtilityFree

- ^ a b c d e f mpoweruk.com: Accumulator and battery comparisons (pdf)

- ^ a b c Mpower: Nickel Iron Batteries

- ^ "Nickel Iron Battery Frequently Asked Questions" BeUtilityFree

- ^ Web archive backup: Edison Battery Booklet original instruction book for the Edison battery

- ^ a b c d e David Linden, Thomas B. Reddy (ed). Handbook Of Batteries 3rd Edition, McGraw-Hill, New York, 2002 ISBN 0-07-135978-8, Chapter 25

- ^ Ian Soutar (July 1, 2010). "Nickel Iron Battery Association HomePage". http://www.nickel-iron-battery.com/. Retrieved October 30, 2011.

- ^ Electrochemistry Edison Cell (Iron-Nickel-Battery) – Model

- ^ a b Journal of Power Sources, 12 (1984). pp 177–192.

External links

- 2009 Data Sheet: Advanced NiFe batteries with high current delivery and very low internal resistance (1st page blank)

- 2005 Journal of Electrochemistry ... First sealed nickel–iron battery opens up new applications

- Zapp Works commercial site

Wikimedia Foundation. 2010.