- Dip pen

-

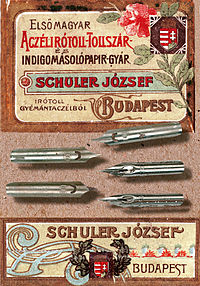

A dip pen or nib pen usually consists of a metal nib with capillary channels like those of fountain pen nibs, mounted on a handle or holder, often made of wood. Other materials can be used for the holder, including bone, metal and plastic, while some pens are made entirely of glass. Generally speaking, dip pens have no ink reservoir; therefore the user has to recharge the ink from an ink bowl or bottle in order to continue drawing or writing. (However, there are simple, tiny tubular reservoirs that illustrators sometimes clip onto dip pens; these allow drawing for several minutes without recharging the nib.) Recharging can be done by dipping into an inkwell; however, some illustrators and cartoonists (who are the main current users of such pens) are more likely to charge the pen with an eyedropper or a syringe, which gives them more control over the amount of ink applied. Thus, "dip pens" are not necessarily dipped. Many illustrators call them "nib pens."

The dip pen has certain advantages over a fountain pen. It can use waterproof pigmented (particle-and-binder-based) inks, such as so-called "India ink", drawing ink, or acrylic inks, which would destroy a fountain pen by clogging it up, as well as the traditional iron gall ink, which can cause corrosion in fountain pens.

There is also a wide range of readily exchangeable nibs available so different types of lines and effects can be created. The nibs and handles are far cheaper than most fountain pens, and allow color changes much more easily.

Dip pens were generally used prior to the development of fountain pens, and are now mainly used in illustration, calligraphy, and comics.

Contents

History

The Jewellery Quarter and surrounding area of Birmingham, England was home to many of the first dip pen manufacturers.

The first steel pen is said to have been made in 1803 (but in Daniel Defoe's book "A Tour Through the Whole Island of Great Britain - 1724-26" Letter VII he wrote: 'the plaster of the ceilings and walls in some rooms is so fine, so firm, so entire, that they break it off in large flakes, and it will bear writing on it with a pencil or steel pen). In Newhall Street, John Mitchell pioneered mass production of steel pens in 1822; prior to that the quill pen had been the most common form of writing instrument. His brother William Mitchell later set up his own pen making business in St Paul's square. The Mitchell family is credited as being the first manufacturers to use machines to cut pen nibs, which greatly sped up the process.

Baker and Finnemore operated in James Street, near St Paul's Square. C Brandauer & Co Ltd., founded as Ash & Petit, traded at 70 Navigation Street. Joseph Gillott & Sons Ltd. made pen nibs in Bread Street, now Cornwall Street. Hinks Wells & Co. traded in Buckingham Street, Geo W Hughes traded in St Paul's Square, Leonardt & Catwinkle traded in George Street and Charlotte Street, and M Myers & Son. were based at 8 Newhall Street. By 1830 John and William Mitchell, Joseph Gillott, and Josiah Mason were the major manufacturers in Birmingham.

In Germany the industrial production of dip pens started in 1842 at the factory of Heintze & Blanckertz in Berlin.

By the 1850s, Birmingham existed as a world centre for steel pen and steel nib manufacture. More than half the steel nib pens manufactured in the world were Birmingham-made. Thousands of skilled craftsmen and women were employed in the industry. Many new manufacturing techniques were perfected in Birmingham, enabling the city's factories to mass produce their pens cheaply and efficiently. These were sold worldwide to many who previously could not afford to write, and encouraged the development of education and literacy. By 1860 there were about 100 companies making steel nibs in Birmingham, but 12 large firms dominated the trade. In 1870 Mason, Sommerville, Wiley, and Perry, merged to form Perry & Co. Ltd. which later became one of the largest manufacturers in the world.

Richard Esterbrook manufactured quill pens in Cornwall. In the 19th century, he saw a gap in the American market for steel nib pens. Esterbrook approached five craftsmen who worked for John Mitchell in Navigation Street with a view to setting up business in Camden, New Jersey, USA. Esterbrook later went on to become one of the largest steel pen manufacturers in the world before eventually going out of business.

One improved version of the dip pen, known as the original "ball point", was the addition of a curved point (instead of a sharp point) which allows the user to have slightly more control on upward and sideways strokes. This feature, however, produces a thicker line rather than the razor-sharp line produced by a sharp point.

The oblique dip pen was designed for writing the pointed pen styles of the mid 19th to the early 20th century such as Spencerian Script, although oblique pen holders can be used for earlier styles of pointed penmanship such as the copperplate scripts of the 18th and 19th centuries. As the name suggests the nib holder holds the nib at an oblique angle of around 55° pointing to the right hand side of the penman. This feature helps greatly in achieving the steep angle of the writing but more importantly prevents the right hand nib tine from dragging on the paper as can be experienced when using a straight nib holder with a straight nib for this purpose.

Pen makers

Some of the more prominent pens manufacturers (in past and present time) are [1]:

Country Manufacturers (Brands) Austria Carl Kuhl, Salcher, Hiro Czechoslovakia Massag England C. Brandauer & Co., Joseph Gillott's, Baker & Finnemore, Perry & Co.,

Josiah Mason, Hinks Wells & Co., Geo W. Hughes, John Mitchell, William Mitchell,

J. B. Mallat, J. Cooke & Sons, M. Myers & Son, D. Leonardt & Co.France Baignol et Farjon, Blanzy-Poure, Cie. Francaise, Plumes Parisiennes Germany Brause, F. Soennecken, Heintze & Blanckertz, Herm. Müller, Leo’s, Pelikan Japan Nikko, Tachikawa, Zebra Spain A. Fabre, Boira, Cervantinas, Campoamor, Daimar, Goya, Imsa, Jaer, Verabil Scotland MacNiven & Cameron United States Richard Esterbrook, Speedball, C. Howard Hunt, Turner & Harrison, Eagle Pencil Co., Bic Co. Uses

Dip pens are rarely used now for regular writing, most commonly having been replaced by fountain pens, rollerball pens, or ballpoint pens. However, dip pens are still appreciated by artists, as they can make great differences between thick and thin lines, and generally write more smoothly than other types of pens. Dip pens are also preferred by calligraphers for fine writing.

Although most of the factories ceased manufacturing dip pens [1], some companies are still active, such as Speedball, Brause, C. Leonardt, Joseph Gillott and William Mitchell.

Gallery

-

A rare pen with the body shaped as the Eiffel Tower.

See also

References

External links

- Speedball website

- Brause website

- D. Leonardt & Co. website

- Scribblers nibs and calligraphy site

- Blam! Design Calligraphy site

- Birmingham Pen Room

- Birmingham Heritage Museum

Types ballpoint (biro) · demonstrator · digital · dip · fountain · gel · ink brush · light · porous point · qalam · quill · rastrum · reed · rollerball · ruling · skin · stylus · technical (rapidograph)Parts and tools pen inks Related Categories:- Writing instruments

- Art materials

- Pens

Wikimedia Foundation. 2010.