- Clarification and stabilization of wine

-

The clarification and stabilization of wine in winemaking involves removing insoluble and suspended materials. The insoluble material causes a wine to be cloudy. These processes may include fining, filtration, centrifugation, flotation, refrigeration, barrel maturation, pasteurization and racking. Most of these processes will occur after the primary fermentation and before the wine is bottled. The exception is for white wine production which will usually have the must separated from some of the grape skins and particles prior to fermentation so as to avoid any unwanted maceration. The timing and exact methods used will vary by producer, depending on the desired finish product -- such as a completely bright and clear wine or a wine that still retains some of the flavor and color phenols. Some of the materials that are removed from the must during this stage of winemaking include dead yeast cells (lees), bacteria, tartrates, proteins, pectins, various tannins and other phenolic compounds, and pieces of grape skins, pulp, stems and gums.[1]

Contents

Clarifying wine

In wine tasting, a wine is considered "clear" when there are no visible particles suspended in the liquid and (mostly in regards to white wines) there is some degree of transparency. This is demonstrated by holding the glass up to a piece of paper with writing and seeing if one could read through the wine. Some red wine grape varieties have a naturally high concentration of coloring phenols that make the wine more translucent or opaque. For these wines, the brightness or "vividness" of the wines color is considered.[2] A wine with a lot of suspended particles will appear less clear and more dull in brightness. While lack of clarity and brightness may not negatively affect the taste of wine, it may make the wine less visually appealing to the consumer. In the modern wine industry there has been a premium placed on wines being both clear and bright. To achieve this, wines are usually clarified through some means in order to remove suspended particles.[1]

These suspended particles are normally insoluble solids such as lees, fragments of grape skins, pulp and seeds as well as colloids that are not visible to the unaided eye like gums, pectins, proteins, tartrates, active yeast and bacteria. The forces of gravity can achieve natural clarification through the process of settling (French débourbage) where the larger suspended particles gradually settle to the bottom of the storage vessel. The wine is then siphoned or "racked" off the compact solids into a new container.[3] This natural process can be very lengthy, sometimes requiring many months or even a couple years as well as several rackings in order to produce a perfectly clear wine. Producers can accelerate the process by using fining agents, filtration or flotation.[1]

The timing of these methods vary depending on producer and type of wine being made. White wine, particularly aromatic varieties such as Riesling and Sauvignon blanc, is often settled and racked soon after the grapes are crushed and pressed. This is to minimize maceration and exposure to the phenolic compounds present in the grapes' skin, seeds and stems that can leach out into the must and cause the wine to prematurely brown in color as well as diminish the fruit flavors of the wine. Other varieties, such as Chardonnay, may spend some time in contact with the skins and particulate matter in order to gain complexity before being settled and racked.[4] To aid in this clarification of white wine, pectin-splitting enzymes, sulfur dioxide and fining agents such as bentonite are added to the must to encourage the agglomeration and settling of the colloids while the holding tank is brought to low temperatures and held for 24 hours prior to rack. While most red wines are clarified after fermentation, the pectin-splitting enzymes may be added prior to fermentation to make post-fermentation clarification easier.[1]

Fining

Main article: FiningsIn winemaking, fining is the process where a substance (fining agent) is added to the wine to create an adsorbent, enzymatic or ionic bond with the suspended particles, making them a larger molecule that can precipitate out of the wine easier and quicker. Unlike filtration, which can only remove particulates (such as dead yeast cells and grape fragments), fining is effective in removing soluble substances such as polymerized tannins, coloring phenols and proteins. Given enough time in a stable environment, many of these suspended particles would gradually precipitate out on their own. The use of fining agents speeds up the process at lower cost. White wines are fined to remove particles that may cause the wine to brown or lose color as well as removing heat-unstable proteins that could cause the wine to appear hazy or cloudy should it be exposed to high temperatures after bottling. Red wines are fined for the same reason but also for the added benefit of reducing the amount of bitter, astringent tannins which makes these wines smoother and more approachable sooner after bottling and release.[5] Throughout history a wide range of substances have been used as fining agents, such as dried blood powder[6], but today there are two general types of fining agents — organic compounds and solid/mineral materials.[5]

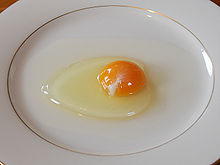

Organic compounds used as fining agents are generally animal based, which may bring concerns for a vegan diet.[7] The most common organic compounds used include egg whites, casein derived from milk, gelatin and isinglass obtained from the bladders of fish. Pulverized minerals and solid materials can also be used as fining agents with bentonite clay being one of the most common fining agent used due to its effectiveness in absorbing proteins and some bacteria. Activated carbon derived from charcoal is used to remove some phenols that contribute to browning colors as well as some particles that produce "off-odors" in the wine.[5] In a process known as blue fining, potassium ferrocyanide is used to remove copper and iron particles that may have entered the wine through the use of metal winery and vineyard equipment, vineyard sprays such as the bordeaux mixture, and the use of bentonite as a fining agent . Due to the potential of potassium ferrocyanide forming hydrogen cyanide, its use is highly regulated and is illegal in many wine producing countries.[8] Other inorganic materials use include silica and kaolin.[5]

Some countries, such as Australia and New Zealand, have wine labeling laws that require the use of fining agents that may be an allergenic substance to appear on the wine label, as there may be trace amounts of the substance still in the wine. However a study conducted by the University of California, Davis Department of Viticulture and Enology found that no detectable amount of inorganic fining agents such as bentonite are present in wine that has been fined and only negligible trace amount of proteinaceous agents such as egg whites can be detected.[5]

As with filtration, there is the risk of some loss of flavor with fining due to desirable flavor molecules being precipitated out along with the more undesirable particles.[4] Some producers of premium wine will do less fining or do it much later in the production process in order to leach as much flavor and aromatics from the phenols before they are removed. Still, fining is considered a less harsh process than filtration, with its advocates believing that it better mimics the natural clarification and stabilization process.[5]

Filtration

Main article: FiltrationWhile fining clarifies wine by binding to suspended particles and precipitating out as larger particles, filtration works by passing the wine through a filter medium that captures particles that are larger than the hole size of the medium. Complete filtration may require a series of filtering through progressively finer filters which can be expensive but will be considerably quicker than letting gravity naturally settle the wine and using racking to siphon the clear wine out. Most filtration in a winery can be classified as either depth filtration or surface filtration.[5]

Depth filtration is often the first type of filtration a wine sees after fermentation when the wine is pushed through a thick layer of pads made from cellulose fibers, diatomaceous earth or perlite which traps the particles and can be removed from the wine. If the producers wish to further filter the wine, they may go to surface filtration. Surface filtration involves running the wine along a thin film of polymer material filled with holes tinier than the particles that are being filtered out. Running the wine parallel to filter surface (known as "Cross-flow" surface filtration) will minimize the amount of potential clogging of the filter. Most membranes are made from plastic or ceramic. Another step in surface filtration, usually taking place right before bottling, is microfiltration where the fine is passed through a membrane with holes small enough to trap yeast and bacteria cells. An alternative to filtration is centrifugation where wine is put through a centrifuge decanter and gravity separates the particles from the wine.[5]

The use of filtration is a controversial subject in winemaking with some producers feeling that the technique strips the wine of too much of its natural flavors and characteristics.[4] Some producers will add the phrase "unfiltered" to their wine label as a marketing tool.[7] Wine can go through a natural clarification and stabilization process by aging in a wood barrel where the subtle oxidative effects can aid in the precipitation of larger particles (particularly proteins, tartrates and malates). This process takes time, however, and producers who bottle their wine too early, and without the assurance of sterile bottling equipment, can risk microbial contamination and instability. Wines that have not been filtered are much more likely to develop sediment as the wine ages.[5]

Flotation

The winemaking technique of flotation was adapted from the froth flotation process used in the mining industry for ore refining. In this process, small bubbles of air (or compressed nitrogen) are injected into the bottom of a tank. As the bubbles rise through the must, grape solids have a natural tendency to cling to the bubbles creating a froth that can be removed from the wine. This technique has to take place prior to fermentation since the biological activity of yeast cells serves as an inhibitor to the flocculation needed for the froth to form. Since phenolic compounds that are prone to oxidation and browning are highly reactive to the air bubbles, wines that have gone through the flotation process are often more resistant to oxidative browning if exposed to air later.[1]

Stabilization

As a chemical substance dependent on the activity of microorganisms and complex chemical reaction, wine can be very unstable and reactive to changes in its environment. After bottling, a wine can be exposed to extremes in temperatures and humidity as well as violent movement during transportation and storage that can encourage the wine to go through additional chemical changes that may produce faults or undesirable traits to emerge in the wine. These can include carbonic gas, formation of sediment deposits or tartrate crystals, hazy or cloudy appearance, rapid deterioration of flavor and spoilage. Eliminating suspended particles in a wine can increase the stability of a wine and prevent some of these undesirable characteristic to emerge. The process of clarification does, in itself, increase the stability of the wine by removing some of these particles. Conversely, the process of stabilization can also increase the clarity and brightness of a wine.[1]

Temperature instability

Tartaric acid is the most prominent acid in wine with the majority of the concentration present as potassium acid salt. During fermentation, these tartrates bind with the lees, pulp debris and precipitated tannins and pigments. While there is some variance among grape varieties and wine regions, generally about half of the deposits are soluble in the alcoholic mixture of wine. The crystallization of these tartrates can happen at unpredictable times if the wine is exposed to low temperature. These crystals can appear in a wine bottle looking like broken glass (though they are in fact harmless) and their presence may be undesirable to consumers. To prevent this from happening after the wine has been bottled, winemakers stabilize the wine by putting it through a cold stabilization process where it is exposed to temperatures below freezing to encourage the tartrates to crystallize and precipitate out of the wine.[9] Some white grape varieties (such as Muscat) have significant quantities of proteins that are "heat-unstable" and will coagulate if the wine is exposed to excessive amount of heat fluctuations, making the wine appear hazy and cloudy. Winemakers will use fining agents, such as bentonite, to remove these proteins and increase the heat stability of the wine.[1]

Microbiological instability

Both active yeast cells and bacteria may be present in a wine after it has gone through the fermentation process and is bottled. If the wine still contains some residual sugar, the active yeast cells will initiate a secondary fermentation process inside the bottle that will create dissolved carbonic gas as a by-product. When the wine is opened, it will be gassy or "sparkling". While this may be a desirable trait for some wines (such as Champagne where a deliberate initiation of a secondary fermentation is part of production), it is not desirable for wines intended to be still or non-sparkling--such as Burgundy Pinot noir or a Washington Merlot. The easiest way to stabilize the wine is to ensure that there is no fermentable sugars left in the wine but in cases where some residual sugar in desirable (such as to balance the acidity of the wine) other methods can be taken to stabilize the wine. One method is sterile filtration and bottling which ensures that no active yeast are present in the wine. Another method is the addition of sulfur dioxide and sorbic acid which can inhibit the growth of yeast cells.[1]

Modern advances in hygiene has eliminated many of the bacterial concerns that contribute to wine stability. Historically the presence of bacteria played a larger role in the developing of various wine faults. The primary concern in modern wineries is the presence of acetobacter which can turn wine into vinegar and lactic acid bacteria that can initiate malolactic fermentation which may not be desirable for certain wines. Acetobacter is active in the presence of oxygen so taking preventative measures, such as the use of sulfur dioxide, can suppress the growth of acetobacter. Eliminating the presence of fermentable sugars and malic acid can inhibit the growth of lactic acid bacteria and stabilize the wine.[1]

Other methods of stabilization

The clarification methods of fining and filtration also act to stabilize wine by removing some of the same particles that can promote instability. The subtle oxidation that occurs with oak barrel aging has a naturally stabilizing effect on the wine.[1]

Pasteurization

A wine can be stabilized by a method of heat sterilization, commonly known as pasteurization. The purpose of this technique is to bring the wine up to high enough temperatures that all micro-organisms in the wine (namely yeast and bacteria) are killed. For kosher wines, the production of mevushal wines (literally "cooked" or "boiled") heat sterilizes the wine to where non-Jews and non-observant Jews can handle the wine and still maintain its kosher status.[10] In the process of pasteurization, wines are brought up to temperatures of 185 °F (85 °C) for a minute and then quickly cooled to a temperature of 122 °F (50 °C) where it is kept for up to 3 days. The wine may then be allowed to cool down to room temperature or be bottled "hot" and cooled by water sprays. This process can be rough on a wine and could diminish flavors and aging potential. A more gentle procedure known as flash pasteurization has been developed which heats the wine to 205 °F (95 °C) for a few seconds, followed by rapid cooling.[11]

Premium wine production

Not all producers decide to thoroughly clarify and stabilize their wines, believing that some of a wine's flavor, aging potential and complexity come from some of the suspended particles. Wine experts, such as Tom Stevenson, notes that techniques like filtration can improve wine quality in moderation but can also diminish quality if used excessively.[3] The consumers of some premium wines (such as Bordeaux and Port) may expect to see tartrates and sediment from a wine that has been aging and not thoroughly filtered.[1]

References

- ^ a b c d e f g h i j k J. Robinson (ed) "The Oxford Companion to Wine" Third Edition, pp. 173, 661–62. Oxford University Press 2006 ISBN 0198609906.

- ^ E. Goldstein "Perfect Pairings" pp. 5–9 University of California Press 2006 ISBN 9780520243774

- ^ a b T. Stevenson "The Sotheby's Wine Encyclopedia" pp. 26–7 Dorling Kindersley 2005 ISBN 0756613248.

- ^ a b c K. MacNeil The Wine Bible pp. 35–40 Workman Publishing 2001 ISBN 1563054345.

- ^ a b c d e f g h i J. Robinson (ed) "The Oxford Companion to Wine" Third Edition pp. 271–72 Oxford University Press 2006 ISBN 0198609906

- ^ J. MacQuitty "Vegan wines", The Times, August 20th 2008

- ^ a b C. Pyevich "Why is Wine so Fined?" Vegetarian Journal, January/February 1997, Volume XVI, Number 1.

- ^ J. Robinson (ed) "The Oxford Companion to Wine" Third Edition, p. 83 Oxford University Press 2006 ISBN 0198609906.

- ^ J. Robinson (ed) "The Oxford Companion to Wine" Third Edition, p. 681 Oxford University Press 2006 ISBN 0198609906.

- ^ S. Retsky"Kosher, Mevushal and Israeli Wines? Not What You Think" American Thinker, December 17th 2005.

- ^ J. Robinson (ed) "The Oxford Companion to Wine" Third Edition p. 508 Oxford University Press 2006 ISBN 0198609906

Categories:

Wikimedia Foundation. 2010.