- Chloroacetic acid

-

Chloroacetic acid

Chloroacetic acidSystematic nameChloroethanoic acid

Chloroacetic acidSystematic nameChloroethanoic acidIdentifiers CAS number 79-11-8

ChemSpider 10772140

UNII 5GD84Y125G

KEGG D07677

ChEBI CHEBI:27869

ChEMBL CHEMBL14090

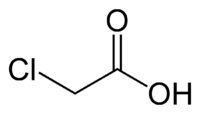

RTECS number AF8575000 Jmol-3D images Image 1 - ClCC(O)=O

Properties Molecular formula C2H3ClO2 Molar mass 94.5 g mol−1 Appearance Colorless or white crystals Density 1.58 g cm−3, solid Melting point 63 °C, 336 K, 145 °F

Boiling point 189.3 °C, 462.5 K, 372.7 °F

Solubility in water 85.8 g/100mL (25 °C) Acidity (pKa) 2.86[1] Hazards MSDS External MSDS R-phrases R25 R34 R50 S-phrases S23 S37 S45 S61 Main hazards alkylating agent NFPA 704 Flash point 126 °C Related compounds Related compounds 2-chloropropionic acid

sodium chloroacetate acid (verify) (what is:

acid (verify) (what is:  /

/ ?)

?)

Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa)Infobox references Chloroacetic acid, industrially known as monochloroacetic acid (MCA) is the organochlorine compound with the formula ClCH2CO2H. This carboxylic acid is a useful building-block in organic synthesis.

Contents

Production

The production of chloroacetic acid was 706,000 tonnes/year in 2010,[2] of which over half is produced in China. Other countries with significant production capacity are Germany (105,000), the Netherlands (100,000), India (>65,000), and the United States (55,000). The world's largest producer is Akzo Nobel.[2]

Processes

Chloroacetic acid is prepared industrially via two routes. The predominant method involves chlorination of acetic acid:

- CH3CO2H + Cl2 → ClCH2CO2H + HCl

Acetic anhydride serves as a catalyst for this reaction.

The other main industrial route to chloroacetic acid is hydrolysis of trichloroethylene using sulfuric acid as a catalyst.

- CCl2CHCl + 2 H2O → ClCH2CO2H + 2 HCl

The hydrolysis method produces a highly pure product, which can be important since mono-, di-, and trichloroacetic acids are difficult to separate by distillation. Approximately, 420,000,000 kg/y are produced globally.[3]

Reactivity and uses

Illustrative of its usefulness in organic chemistry is the O-alkylation of salicylaldehyde with chloroacetic acid, followed by decarboxylation of the resulting ether, producing benzofuran.[4]

In industry, chloroacetic acid is used in the production of a wide variety of useful compounds, e.g., drugs, dyes, pesticides.[3] Most reactions taking advantage of the high reactivity of the C–Cl bond. It is the precursor to the herbicide glyphosate. The herbicides MCPA (2-methyl-4-chlorophenoxyacetic acid) and dimethoate are prepared by alkylation with chloroacetic acid. Chloroacetic acid is converted to chloroacetyl chloride, a precursor to adrenaline (epinephrine). Displacement of chloride by sulfide gives thioglycolic acid, which is used as a stabilizer in PVC and a component in some cosmetics.

In its largest-scale application, chloroacetic acid is used to prepare the thickening agent carboxymethyl cellulose and carboxymethyl starch.

Safety

Like other chloroacetic acids and related halocarbons, chloroacetic acid is a potentially dangerous alkylating agent. The LD50 for rats is 76 mg/kg.[3]

Chloroacetic acid easily penetrates skin and mucous membranes and interferes with cellular energy production. Initial dermal exposure to high concentrations (e.g., 80% solution) may not appear very damaging at first, however systemic poisoning may present within hours. Exposure can be fatal if greater than 6% body surface area is exposed to chloroacetic acid. The sodium salt does not penetrate the skin as well as the acid but can be as damaging given a longer duration and greater surface area of exposure.

Upon one's exposure to chloroacetic acid, immediate decontamination should be commenced by rinsing the affected area with water or bicarbonate solution in order to neutralize the acid and prevent further skin absorption.

The antidote of chloroacetic acid poisoning is sodium dichloroacetate (50 mg/kg IV over 10 mins, repeated in 2h; double dosage if hemodialysis is performed).[citation needed]

See also

- Chloroacetic acids

- Dichloroacetic acid

- Trichloroacetic acid

- Chloracetyl chloride

References

- ^ Dippy, J.F.J., Hughes, S.R.C., Rozanski, A., J. Chem Soc., 1959, 2492.

- ^ a b M.P. Malveda (july 2011). "CEH Marketing Research Report: MONOCHLOROACETIC ACID". Chemical Economics Handbook. SRI consulting. http://www.sriconsulting.com/CEH/Public/Reports/676.1000/. Retrieved July 2011.

- ^ a b c Günter Koenig, Elmar Lohmar, Norbert Rupprich "Chloroacetic Acids" in Ullmann's Encyclopedia of Industrial Chemistry 2002, Wiley-VCH, Weinheim. doi:10.1002/14356007.a06_537

- ^ Burgstahler, A. W.; Worden, L. R. (1966). "Coumarone." Org. Synth. 46: 28.

External links

- "Monochloroacetic Acid". Dow Chemical. http://www.dow.com/webapps/lit/litorder.asp?filepath=gco/pdfs/noreg/103-00133.pdf&pdf=true. Retrieved 20 May 2007.

- "Monochloroacetic Acid". IPCS Inchem. http://www.inchem.org/documents/pims/chemical/pim352.htm. Retrieved 20 May 2007.

Categories:- Acetic acids

- Organochlorides

Wikimedia Foundation. 2010.