- Metal oxide adhesion

-

The strength of metal oxide adhesion effectively determines the wetting of the metal-oxide interface. The strength of this adhesion is important, for instance, in production of light bulbs and fiber-matrix composites that depend on the optimization of wetting to create metal-ceramic interfaces[1] The strength of adhesion also determines the extent of dispersion on catalytically active metal.[1] Metal oxide adhesion is important for applications like complementary metal oxide semiconductor devices. These devices make possible the high packing densities of modern integrated circuits.

Contents

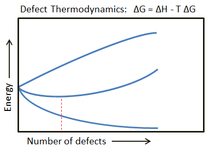

Oxide Thermodynamics

The majority of the entropy of metal oxidation reactions is in the O2(g) because the gaseous oxygen molecules have translation entropy which is not present in the solid phase. For this reason, the change in entropy (ΔS) for oxidation is most always negative because this reaction generates less disorder by creating a solid oxide layer from the solid metal and gaseous oxygen. The standard state change of enthalpy is relatively independent and thus the gradient of the change in Gibbs free energy as a function of temperature is linear. This dictates that an oxide becomes less thermodynamically stable with increasing temperature.

An important distinction between equilibrium wetting and non-equilibrium wetting is that the non-equilibrium condition occurs when a chemical reaction is taking place. This non-equilibrium wetting is an irreversible thermodynamic process that accounts for the changes of the chemical potential when forming a new boundary phase, such as an oxide.

Work of Adhesion

The ideal work of separation Wsep is the reversible work needed to separate the interface into two free surfaces.[2] Important as a state function depending on the mechanical properties.[2] It is referred to as ideal because when the two free surfaces create an interface, the concentration of the interface will only be identical to the bulk at the instant the surface is created. In order to reach chemical equilibrium, the process of diffusion will take place which will increase any measurement of the work of separation.[2] The work of adhesion is the reversible free energy change for making free surfaces from interfaces.[2] It is represented by the equation:

-

- Wad = γm + γo − γmo

where:

Wad is the work of adhesion

γm and γo are the respective surface energies of the metal and oxide

γmo is the surface energy between the two materials in contact

The following table gives some common metals and their corresponding surface energies. All the metals are face-centered cubic crystal structure and these surface energies correspond to the (100) surface plane.

Material Surface Energy J / m − 2 Al 1.347 Pb 0.377 Yb 0.478 Cu 2.166 Pd 2.326 Ag 1.200 Pt 2.734 Au 1.627 Oxide Stability

Ellingham diagrams are generated according to the second law of thermodynamics and are a graphical representation of the change in the Gibbs free energy with respect to changing temperature for the formation of oxides.

Solid-Gas Interface

Structure

Real surfaces may be macroscopically homogeneous, but their microscopic heterogeneity plays a crucial role in the relationship between the metal and its oxide.

Transition Metal Oxides

A diagram showing different layers of transition metal oxides formed on the surface of a metal.

Certain transition metals form multiple oxide layers that have different stoichiometric compositions. This is due to the metal having different valency states that have fewer or greater electrons in the valence shell. These different valency states allow for multiple oxides to be formed from the same two elements. As the composition of the materials changes through diffusion, different oxides are able to stack up on one another. The adhesion in this situation involves the metal-oxide and oxide-oxide interfaces which add increasing complexity to the mechanics.[3]

Roughness

Increasing surface roughness increases the number of dangling bonds at the metal-oxide interface. The surface free energy of a crystal face is:

-

- γ = E − TS

where:

E is the binding energy of the materialT is the temperature of the system

S is the surface entropy of the material

The binding energy favors a smoother surface that minimizes the number of danging bonds, while the surface entropy term favors a rougher surface with increasing dangling bonds as the temperature is increased.[4]

Heterogeneity

Solid adsorption of an oxygen molecule depends on the heterogeneity of the substrate. Crystalline solid adsorption is dependent on the exposed crystal faces, grain orientations, and inherent defects because these factors provide adsorption sites with different steric configurations. Adsorption is largely determined by the reduction of gibbs free energy associated with the exposed substrate.

Crystallographic Orientation

A material's charge remains neutral when a surface is created by the law of charge conservation, but individual Bravais lattice planes, defined by their Miller indices, may be non-polar or polar based on their symmetry. A dipole moment increases the surface gibbs free energy, but the greater polarizability of oxygen ions as compared to metals allows polarization to decrease the surface energy and thus increase the ability of metals to form oxides. Consequently, different exposed metal faces may adhere weakly to non-polar oxide faces, but be able to perfectly wet a polar face.

Defects

Surface defects are the localized fluctuations of surface electronic states and binding energies. Surface reactions, adsorption, and nucleation can be drastically affected by the presence of these defects.[5]

Vacancies

Oxide growth is dependent upon the flux (diffusion) of either coupled or independent anions and cations through the oxide layer.[6][7] Stoichiometric oxides have an integer ratio of atoms can only support coupled diffusion of anions and cations through the lattice migration of Schottky defects (paired anion/cation vacancies) or Frenkel defects (complete anion lattice with cation vacancies and intersticials).[6][7] Non-stoichiometric oxide films support independent ion diffusion and are either n-type (extra electrons) or p-type (extra electron holes). Although there are only two valence states, there are three types:[6][7]

- cation excess (n-type)

- anion deficit (n-type)

- cation deficit (p-type)

Non-stoichiometric oxides most commonly have excess metal cations as a result of insufficient oxygen during the creation of the oxide layer. Excess metal atoms with a smaller radius than O2- anions are ionized within the crystal lattice as interstitial defects and their lost electrons remain free within the crystal, not taken by the oxygen atoms. The presence of mobile electrons within the crystal lattice significantly contributes to the conduction of electricity and the mobility of ions.[6]

Impurities

Impurity elements in the material can have a large effect on the adhesion of oxide films. When the impurity element increases the adherence of the oxide to the metal it is known as the reactive element effect or RE effect. Many mechanics theories exist on this topic. The majority of them attribute the increase in adhesion strength to the greater thermodynamic stability of the impurity element bonded with oxygen than the metal bonded to the oxygen.[2][8] Inserting yttrium into nickel alloys to strengthen the oxide adhesion is an example of the reactive element effect.

Dislocations

Dislocations are thermodynamically unstable, kinetically trapped defects. Surface dislocations often create a screw dislocation when stress is applied. In certain cases, screw dislocations can negate the nucleation energy barrier for crystal growth.[5]

Oxide-Support Relationship

The adsorption of a monolayer of gas atoms is either commensurate or incommensurate. Commensurate adsorption is defined by having a crystal structure relationship between substrate-adsorbate layer that produces a coherent interface. Wood's notation is a description of the relationship between the simplest repeating unit area of the solid and adsorbate. The difference between the resulting commensurate interfaces can be described as an effect of misfit. The interfacial interaction can be modeled as the

sg plus the stored elastic displacement energy due to lattice misfit. A large misfit corresponds to an incoherent interface where there is no coherency strain and the interface energy can be taken as simply the

sg plus the stored elastic displacement energy due to lattice misfit. A large misfit corresponds to an incoherent interface where there is no coherency strain and the interface energy can be taken as simply the  sg. In contrast, a small misfit corresponds with a coherent interface and coherency strain that results in the interfacial energy equivalent to the minimum

sg. In contrast, a small misfit corresponds with a coherent interface and coherency strain that results in the interfacial energy equivalent to the minimum  sg.[9]

sg.[9]Strength of Bond

The strength of the bond between the oxide and metal for the same nominal contact area can range from Pa to GPa stresses. The cause of this huge range stems from multiple phenomena dealing with at least four different types of adhesion. The main types of bonding that form adhesion are electrostatic, dispersive (van der Waals or London forces), chemical and diffusive bonding. As the adhesive forces increase, separation in crystalline materials can go from elastic debonding to elasic-plastic debonding. This is due to a larger number of bonds being formed or an increase in strength of the bonds between the two materials. Elastic-plastic debonding is when local stresses are high enough to move dislocations or make new ones.[10]

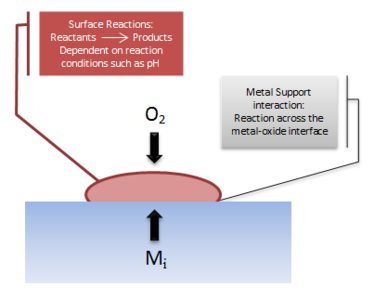

Solid-Gas Kinetics

When a gas molecule strikes a solid surface the molecule may either rebound or be adsorbed. The rate at which gas molecules strike the surface is a large factor in the overall kinetics of oxide growth. If there molecule is absorbed there are three potential outcomes. The surface interaction can be strong enough to dissociate the gas molecule into separate atoms or constituents. The molecule may also react with surface atoms to change its chemical properties. The third possibility is solid surface catalysis, a binary chemical reaction with a previously adsorbed molecule on the surface.

Dispersion

Most often it is kinetically favorable for the growth of a single oxide monolayer to be completed before the growth of subsequent layers. Dispersion in general can be modeled by:

where:

Ns is the number of atoms on the surface

Nt is the total number of atoms in the material

Dispersion is crucial to the growth of oxides because only atoms that are exposed to the interface can react to form oxides.

Diffusion

After the initial oxide monolayer is formed, new layers begin to build and the ions must be able to diffuse through the oxide in order to increase thickness of the oxide. The rate of oxidation is controlled by how fast these ions are able to diffuse through the material. As the thickness of the oxide increases, the rate of oxidation decreases because it requires the atoms to travel a further distance. This rate can quantified by calculating the rate of diffusion of vacancies or ions using Fick’s first law of diffusion.[11]

where:

J is the flux and has units of mol·m−2·s−1

D is the diffusivity of the ions in the materialδC is the change in concentration of the material

δx is the thickness of the oxide layerSolid Surface Catalysis

In 2007 the Nobel Prize in chemistry was awarded to Gerhard Ertl for the study of solid-gas interface molecular processes. One such process is the oscillatory kinetic catalysis. Oscillatory kinetic catalysis can be explained by different crystal surfaces favoring unmodified faces and reconstruction to reduce surface strain. The presence of CO can cause the reversal of surface reconstruction past a certain percent coverage. Once the reversal occurs, oxygen can be chemisorbed on the reverted surfaces. This produces a adsorption pattern with areas of surface coverage rich in CO and others O2.[12]

Driving Force

The driving force of catalysis is determined by the difference between the unprimed equilibrium and the instantaneous interfacial free energies.[2]

See also

- Oxide

- Crystallographic defect

- Corrosion

- Oxidation potential

- Reduction potential

- Pourbaix diagram

- Ellingham diagram

- MOSFET

- Metal oxide varistor

- Surface Properties of Transition Metal Oxides

References

- ^ a b Peden, C; K.B. Kidd, N. D. Shinn (1991). "Metal/Metal-Oxide Interfaces: A surface science approach to the study of adhesion". The Journal of Vacuum and Science Technology (9): 1518–1524.

- ^ a b c d e f Finnis, M W (1996). "The theory of metal-ceramic interfaces". Journal of Physics, Condensed Matter (8): 5811–5836.

- ^ Henrich, Victor; Cox P A (1996). The Surface Science of Metal Oxides. Cambridge University Pre. ISBN 0521566878.

- ^ Libbrecht, Kenneth (2005). "The physics of snow crystals". Reports on Progress in Physics 68: 855–895. doi:10.1088/0034-4885/68/4/R03.

- ^ a b Butt, Hans-Jurgen; Karlheinz Graf, Michael Kappl (2006). Physics and Chemistry of Interfaces. WILEY-VCH. pp. 167–169.

- ^ a b c d Kasap, S.O. (2006). Principle of Electron Materials and Devices. McGraw-Hill. pp. 73–75. ISBN 978-0-07-295791-4.

- ^ a b c Behrens, Malte. "Solid State Kinetics". Lecture Series. Fritz Haber Institute of the Max Planck Society Department of Inorganic Chemistry. http://www.fhi-berlin.mpg.de/acnew/groups/nanostructures/pages/teaching/pages/teaching__malte_behrens__solid_state_kinetics.pdf. Retrieved 1 June 2011.

- ^ Pint, B A (2010). "Progress in Understanding the Reactive Element Effect Since the Whittle and Stringer Literature Review". Metals and Ceramics Division 18 (18): 2159–2168.

- ^ Johansson, Sven; Mikael Christensen, Goran Wahmstrom (2005). "Interface energy of semicoherent metal-ceramic interfaces". Physics Review Letters 95 (22): 226108. doi:10.1103/PhysRevLett.95.226108.

- ^ Gerberich, W W; M J Cordill (2006). "Physics of Adhesion". Reports on Progress in Physics 69: 2157–2204. doi:10.1088/0034-4885/69/7/R03.

- ^ Rutter, N A. "Environmental Stability of Materials". Lecture Series. University of Cambridge. http://www.msm.cam.ac.uk/teaching/partIB/courseB.php. Retrieved 6 June 2011.

- ^ Ertl, Gerhard. "Chemical Processes on Solid Surfaces". Nobel Prize. The Royal Swedish Academy of Sciences. http://nobelprize.org/nobel_prizes/chemistry/laureates/2007/chemadv07.pdf. Retrieved 6 June 2011.

Categories:- Oxides

-

Wikimedia Foundation. 2010.