- Napier Nomad

-

Nomad Napier Nomad II Type Turbo-compound aero-engine National origin United Kingdom Manufacturer Napier & Son First run October 1949 Major applications Avro Lincoln (test bed only) Program cost £5.1 million The Napier Nomad was a complex British compression-ignition aircraft engine designed and built by Napier & Son in 1949. Two versions were flight tested:

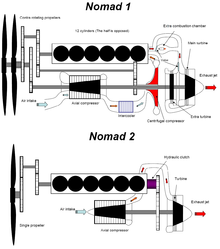

- The Nomad I diesel engine drove one of a pair of contra-rotating propellers with the Napier Naiad based turbine driving the other propeller as a turboprop and also supercharging the diesel unit.

- The later Nomad II used the turbine to boost the manifold pressure of the diesel unit and was also coupled to the crankshaft, this version drove one propeller only. The resulting unit set the lowest specific fuel consumption figures seen up to that time,[1] despite this the project was cancelled in 1955 after interest in the project had passed and £5.1 million had been spent on development.[2]

Contents

Design and development

In 1945 the Air Ministry asked for proposals for a new 6,000 horsepower (4,500 kW) class engine with good economy. Curtiss-Wright was designing an engine of this sort of power known as the Turbo-compound engine, but Sir Harry Ricardo, one of Britain's great engine designers, suggested that the most economical combination would be a similar design using a diesel two-stroke in place of the Curtiss's petrol engine.

Before World War II Napier had licensed the Junkers Jumo 204 diesel design to set up production in the UK as the Napier Culverin, but the onset of the war made the Sabre all-important and work on the Culverin was stopped. In response to the Air Ministry's 1945 requirements Napier dusted off this work, combining two enlarged Culverins into an H-block similar to the Sabre, resulting in a massive 75-litre design. Markets for an engine of this size seemed limited, however, so instead they reverted to the original Sabre-like horizontally opposed 12 cylinder design, and the result was the Nomad.

The objective of the design was to produce a civilian power plant with far superior fuel efficiency to the emerging jet engine. Thermal efficiency is given by 1-(Tx/Tp), where Tx is the exhaust temperature (any absolute scale) and Tp is the peak combustion temperature. Jet engines always have a Tp of no more than about 1000 Kelvin, much less than the typical 5000 Kelvin of a reciprocating engine, and so jets have very poor thermal efficiency. The Nomad design focused on replacing the low temperature combustion chambers of the jet engine with highly efficient Diesel combustion chambers. In practice, it was much too difficult to couple the Diesel power output back into the turbine cycle. The maximum practical power of the Nomad was 4,000 horsepower (3,000 kW), and it was much heavier than a pure jet of the same power. By this time civilian jets such as the Boeing 707 were nearing completion, and the Nomad was never seriously considered by any aircraft manufacturer.

Nomad I

The initial Nomad design (E.125) or Nomad 3 was incredibly complex, essentially two engines in one. One was a turbo-supercharged diesel similar to the upper half of a Napier Sabre. Mounted below this was a complete turboprop engine, based on their Naiad design, the output of which was geared to a shaft driving the front propeller of a contra-rotating pair, as well as the axial compressor. To achieve higher boost, a centrifugal supercharger was used. This was driven by the crankshaft, which also provided the scavenging needed for starting this two-stroke engine from rest, before the turbine section was up to speed. As if that were not enough complexity, during takeoff additional fuel was injected into the rear turbine stage for more power, and turned off once the aircraft was cruising.[3]

The compressor and turbine assemblies of the Nomad were tested during 1948, and the complete unit was run in October 1949. The prototype was installed in the nose of an Avro Lincoln heavy bomber for testing: it first flew in 1950 and appeared at the Farnborough Air Display on 10 September 1951.[4] In total the Nomad I ran for just over 1,000 hours, and proved to be rather temperamental, but when running properly it could produce 3,000 horsepower (2,200 kW) and 320 lbf (1.4 kN) thrust. It had a specific fuel consumption (sfc) of 0.36 lb/(hp·h) (0.22 kg/(kW·h)).

The prototype Nomad I is on display at the National Museum of Flight at East Fortune Airfield in Scotland.

Nomad II

Even before the Nomad I was running, its successor, the Nomad II (E.145) Nomad 6, had already been designed. In this version an extra compressor stage was added, replacing the original supercharger. This stage was driven by an additional stage in the turbine, so the system was now more like a turbocharger and the compressed air for the Diesel was no longer "robbing" power for the turboprop. In addition the propeller shaft from the turbine was eliminated, and geared using a hydraulic clutch into the main shaft. The result was smaller and considerably simpler: a single engine driving a single propeller.[5] Overall about 1,000 lb (450 kg) was taken off the weight. The wet liners of the cylinders of the Nomad I were changed for dry liners.[6] While the Nomad II was undergoing testing, a prototype Avro Shackleton was lent to Napier as a testbed. The engine proved bulky, like the Nomad I before it, and in the meantime several dummy engines were used on the Shackleton for various tests.

A further development, the Nomad Nm.7, of 3,500 shp (2,600 kW) was announced in 1953.[7]

By 1954 interest in the Nomad was waning, and after the only other project, the Avro Type 719 Shackleton IV, based on it was cancelled, work on the engine was ended in April 1955, after an expenditure of £5.1 million.

A Nomad II is on display at the Steven F. Udvar-Hazy Center in Virginia.

Specifications (Nomad II)

Data from Flight 1954[8]

General characteristics

- Type: Twelve-cylinder, two-stroke valveless diesel engine compounded with three-stage turbine driving both crankshaft and axial compressor.

- Bore: 6.00 inches (152 mm)

- Stroke: 7.375 inches (187.3 mm)

- Displacement: 2,502 in³ (41.1 L)

- Length: 119 inches (3,000 mm)

- Width: 56.25 inches (1,429 mm)

- Height: 40 inches (1,000 mm)

- Dry weight: 3,580 pounds (1,620 kg)

Components

- Valvetrain: Piston ported two-stroke

- Supercharger: Napier Naiad turboshaft and gas generator, maximum boost pressure 89 psi

- Turbocharger: Engine exhaust gases ducted in to Naiad turbine section

- Fuel type: Diesel oil or kerosene or wide-cut petrol or "other fuels"

- Cooling system: Liquid-cooled

Performance

- Power output: 3,150 ehp (2,344 kW) max take-off at 89 psi (610 kPa)(208"Hg)(6.9Atm) boost including 320 lbf residual thrust from the turbine at 2,050 rpm (crankshaft) and 18,200 rpm (turbine)

- Specific power: 1.25 ehp/in³ (57.0 kW/L)

- Compression ratio: 8.1 (cylinder ratio), 31.5:1 (combined pressure ratio)

- Specific fuel consumption: 0.345 lb/(ehp·h) (0.210 kg/(kW·h))(combined unit) at 11,000 ft and 300 knots

- Power-to-weight ratio: 0.88 ehp/lb (1.44 kW/kg)

Turbine section

General characteristics

- Type: Gas generator based on Napier Naiad

- Length:

- Diameter:

- Dry weight:

Components

- Compressor: 12-stage axial flow compressor

- Turbine: 3-stage axial flow

Performance

- Maximum thrust: 320 lbf residual at 18,200 rpm

- Overall pressure ratio: 8.25:1

- Power-to-weight ratio:

See also

- Comparable engines

- Related lists

Notes

- ^ Gunston, Bill (1989). World Encyclopaedia of Aero Engines. Cambridge, England: Patrick Stephens. p. 106. ISBN 1-85260-163-9.

- ^ "Cancelled projects: the list up-dated" (PDF). Flight: 262. 17 August 1967. http://www.flightglobal.com/pdfarchive/view/1967/1967%20-%201672.html.

- ^ Lumsden 2003 p170

- ^ Lumsden 2003 p172

- ^ Lumsden 2003 p171

- ^ Flight 1954 p550

- ^ Flight Nov 1953 p 610

- ^ Gunston, Bill (30 April 1954). "Napier Nomad: An engine of outstanding efficiency" (PDF). Flight: 543–551. http://www.flightglobal.com/pdfarchive/view/1954/1954%20-%201215.html. Retrieved 18 December, 2009.

References

- Lumsden, Alec (2003). British Piston Engines and their Aircraft. Marlborough, Wiltshire: Airlife Publishing. pp. 170. ISBN 1-85310-294-6.

External links

- Photo of a Napier Nomad at Enginehistory.org

- "Napier Nomad" a 1952 Flight advertisement for the Nomad engine

Napier aero engines Piston engines Turboprop / Turboshaft Coupled Naiad · Eland · Gazelle · Naiad

Turbo-compound Nomad

Gas-generator Rocket Lists relating to aviation General Aircraft (manufacturers) · Aircraft engines (manufacturers) · Airlines (defunct) · Airports · Civil authorities · Museums · Registration prefixes · Rotorcraft (manufacturers) · TimelineMilitary Accidents/incidents Records Categories:- Napier aircraft engines

- Turbo-compound engines

- Aircraft diesel engines

- Boxer engines

- Turboprop engines 1940-1949

- Two-stroke aircraft piston engines

- Aircraft piston engines 1940-1949

- Diesel engines by model

- Diesel engines by maker

Wikimedia Foundation. 2010.