- Napier Deltic

-

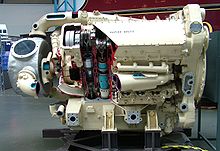

The Napier Deltic engine is a British opposed-piston valveless, two-stroke diesel engine used in marine and locomotive applications, designed and produced by Napier & Son. The cylinders were divided in three blocks in a triangular arrangement, the blocks forming sides with crankcases located in each apex of the triangle.

The term Deltic (meaning in the form of the Greek letter Delta) is used to refer to both the Deltic E.130 opposed-piston high-speed diesel engine and the locomotives produced by English Electric using these engines, including their demonstrator locomotive named DELTIC and the production version for British Railways, who designated these as (TOPS) Class 55.

A single half-sized, turbocharged Deltic power unit also featured in the English Electric-built Type 2 locomotive, designated as the Class 23. Both locomotive and engine became better known as the "Baby Deltic".

Contents

History and design

The Deltic story began in 1943 when the British Admiralty set up a committee to develop a high-power, lightweight diesel engine for Motor Torpedo Boats.[1] Hitherto in the Royal Navy, such boats had been driven by petrol engines but this fuel is highly flammable, making them vulnerable to fire, and at a disadvantage compared with the German diesel-powered E-boats.

Until this time, diesel engines had poor power-to-weight ratio and low speed. Before the war, Napier had been working on an aviation diesel design known as the Culverin after licensing versions of the Junkers Jumo 204. The Culverin was an opposed-piston two-stroke design. Instead of each cylinder having a single piston and being closed at one end with a cylinder head, the Jumo-based design used an elongated cylinder containing two pistons moving in opposite directions towards the centre. This negates the need for a heavy cylinder head, as the opposing piston filled this role. On the downside, the layout required separate crankshafts on either end of the engine, and some form of gearing to take off power and combine it back into a single shaft. The primary advantage of the design was that it led to a rather "flat" engine, intended to be buried in the wings of large aircraft.

The Admiralty required a much more powerful engine, and knew about Junkers' designs for multi-crankshaft engines of triangular-[citation needed] and diamond-form. The Admiralty felt these would be a reasonable starting point for the larger design it required. The result was a triangle, the cylinder banks forming the sides, and tipped by three crankshafts, one at each apex. The crankshafts were connected with phasing gears to drive one output shaft. In this arrangement, there were six banks of pistons driving three crankshafts, the same as three separate V-engines of the same overall size. Various models of Deltic engine could be produced with varying numbers of cylinders, though nine and eighteen cylinders were the most common, having three and six cylinders per bank respectively. In 1946, the Admiralty placed a contract with the English Electric Company, parent of Napier, to develop this engine.[1]

One feature of the engine was the way the crankshaft-phasing was arranged to allow for exhaust port lead and inlet port lag. These engines are called 'uniflow' designs because the flow of gas into and out of the cylinder is one way, assisted by mild supercharging to improve cylinder exhaust scavenging. The inlet/outlet port order is In/Out/In/Out/In/Out going around the triangular ring (i.e. the inlet and outlet manifold arrangements have C3 rotational symmetry).[2]

Earlier attempts at designing such an engine failed because of the difficulty in arranging the pistons to move in the correct manner, for all three cylinders in one delta, and this was the problem which caused Junkers Motorenbau to leave behind work on the delta-form while continuing to prototype of a diamond-form four-crankshaft 24-cylinder Junkers Jumo 223. Mr. N. Penwarden of the Admiralty Engineering Laboratory solved this problem by suggesting that one crankshaft needed to revolve anti-clockwise to achieve the correct piston-phasing, so Napier designers produced the necessary gearing in order that one of them rotated in the opposite direction to the other two.

In an opposed-piston design with no inlet or exhaust valves, and no ability to vary the port positions, the Deltic design arranged each crankshaft to connect two adjacent pistons operating in different cylinders in the same plane, using "fork and blade" connecting rods, the latter an 'inlet' piston used to open and close the inlet port, and the former an 'exhaust' piston in the adjacent cylinder to open and close the exhaust port.

Crankshaft connecting-rod journals were arranged so that each cylinder's exhaust piston 'led' its inlet piston by 20 degrees of crankshaft rotation. This allowed the exhaust port to be opened well before the inlet port, and allowed the inlet port to be closed after the exhaust port, which led to both good scavenging of exhaust gas, and good volumetric efficiency for the fresh air charge. It also led to Deltics' even, buzzing exhaust note, with a charge ignition every 20 degrees of crankshaft revolution, and a lack of torsional vibration, ideal for use in mine-hunting vessels.

Although the engine was cylinder-ported and required no poppet valves, it did still have camshafts, with each bank having a separate camshaft, driven at crankshaft speed. This was used solely to drive the fuel injection pumps, each cylinder having its own injector and pump, driven by its own cam lobe.

Uses

The Deltic-powered Hunt class Mine Countermeasures Vessel HMS Ledbury

The Deltic-powered Hunt class Mine Countermeasures Vessel HMS Ledbury

Development began in 1947 and the first Deltic unit was produced in 1950. By January 1952 six engines were available, enough for full development and endurance trials. S212[citation needed], a captured ex-German E-Boat powered by three Mercedes-Benz diesel engines, was selected for these trials, since its power units were of approximately equal power to the new 18-cylinder Deltic engines. Two of the three Mercedes-Benz engines were replaced with Napier Deltics, the compactness of the Deltic being graphically illustrated: they were half the size of the original engines. The Deltic weighed one fifth of its contemporaries of equivalent power.[1]

Proving successful, Deltic diesel engines became a common powerplant in small and fast naval craft. The Royal Navy used them first in the Dark class fast attack craft.[3] Subsequently they were used in a number of other smaller attack craft. The low magnetic signature lent itself to use in mine countermeasures vessels and the Deltic was selected to power the Ton class minesweeper. The Deltic engine is still in service in the Hunt class. These versions are de-rated to reduce engine stress.

Deltic diesels served in MTBs and PT Boats built for other navies. Particularly notable was the Norwegian Tjeld or Nasty class, which was also sold to Germany, Greece, and the United States Navy. Nasty class boats served in the Vietnam War, largely for covert operations.

Smaller nine-cylinder Deltic 9 engines were used as marine engines, notably by minesweepers. The Ton class vessels were powered by a pair of Deltic 18s and used an additional Deltic 9 for power generation for their magnetic influence sweep.[4] The Hunt class used three Deltic 9s, two for propulsion and again one for power generation, but this time with a hydraulic pump integrated as well to power bow-thrusters for slow-speed manœuvring.[5]

Railway use

Main articles: British Rail Class 55 and British Rail Class 23The 'Deltic' engines were used in two types of British rail locomotive: classes 55 and 23, built in the 1960s. Because of their engines, these types were nicknamed "Deltics" and "Baby Deltics" respectively.

The Class 55 used two D18-25 Deltic engines: mechanically-blown 18-cylinder engines of 1,650 hp (1,230 kW) each, the Class 23 used a single less powerful nine-cylinder turbocharged T9-29 Deltic of 1,100 hp (820 kW).[6][7]

Reliability in service

While the Deltic engine was successful[vague] and very powerful for its size and weight, it was a highly-strung unit, requiring careful maintenance. This led to a policy of unit replacement rather than repair in situ. Deltic engines were easily removed after breakdown, generally being sent back to the manufacturer for repair, although after initial contracts expired both the Royal Navy and British Railways set up their own workshops for overhauls.[8]

Turbo-compound Deltic

The E.185 or Compound Deltic turbo-compound variant was planned[1] and a single prototype was built in 1956[9] and tested in 1957.[10] This capitalised on Napier's experience with both the Nomad and their increasing involvement with gas turbines. It used the Deltic as the gas generator inside a gas turbine, with both a twelve-stage axial compressor and a three stage gas turbine. Unlike the Nomad, this turbine was not mechanically coupled to the crankshaft but merely drove the compressor. It was hoped to produce 6,000 horsepower[citation needed], with fuel economy and power-to-weight ratio "second to none".[11] Predictions by the engineers closely connected with it were that connecting rod failure would be the limit on this power, failing at around 5,300 bhp. On test it actually produced 5,600 bhp, before throwing a connecting rod through the crankcase just as predicted.[9] Naval interest had waned by 1958 in favour of the pure gas turbine, despite its heavier fuel consumption, and no further development was carried out.

Comparable engines

- Zvezda M503

Further reading

- Bryan 'Bob' Boyle (2000). The Napier Way. Bookmarque Publishing. ISBN 1-870519-57-4.

- Alan Vessey (compiler) (1997). Napier Powered. Tempus. ISBN 0-7524-0766-X.

- Brian Webb (1982). The Deltic Locomotives of British Rail. David&Charles. ISBN 0-7153-8110-5.

References

- ^ a b c d D. K. Brown & George Moore (2003). Rebuilding the Royal Navy. Warship design since 1945. Chatham Publishing. ISBN 1-8617-6222-4.

- ^ End on image of Deltic type engine with exhaust manifolds exposed (via the Deltic Presevation Society - Baby Deltic project) thedps.co.uk

- ^ Here and There. "A 2,500 hp Two-stroke" (PDF). Flight: 392. 2 April 1954. http://www.flightglobal.com/pdfarchive/view/1954/1954%20-%200870.html. Retrieved 23 December 2009. "POWERING H.M. fast patrol boat Dark Hunter, launched on March 18th, is a Napier Deltic engine. An opposed-piston two-stroke diesel, it develops 2,500 s.h.p.; its power/weight ratio (4.2 lb/h.p.) is said to be the highest ever achieved in a marine diesel."

- ^ Vessey, Napier Powered, p. 102

- ^ Vessey, Napier Powered, p. 104

- ^ Vessey, Napier Powered, p. 110

- ^ Webb, Deltic Engines, p. 50

- ^ Webb, Brian (1982). The Deltic Locomotives of British Rail. Newton Abbot: David & Charles. ISBN 0-7153-8110-5.

- ^ a b Boyle, The Napier Way, p. 121

- ^ Vessey, Napier Powered, pp. 107-108

- ^ Boyle, The Napier Way, p. 221

External links

- Deltic technical details.

- The Deltic Preservation Society.

- Hunt Class Deltic powered Mine Countermeasure Vessel.

- Deltic Animations 3-D animations of the piston motion in the Deltic engine.

Reciprocating engines and configurations Type Bourke · Controlled combustion · Deltic · Orbital · Piston · Pistonless (Wankel) · Radial · Rotary · Single · Split cycle · Stelzer · TschudiStroke cycles Engine

configurationsI2 · I3 · I4 · I5 · I6 · I7 · I8 · I9 · I10 · I12 · I14F2 · F4 · F6 · F8 · F12 · F16Other inlineComponents Cylinder head porting · Corliss · Intake · Exhaust · Multi · Overhead · Piston · Piston (steam engine) · Poppet · Side · Sleeve · Slide · Rotary valve · Variable valve timing · Camless · DesmodromicCam · Camshaft · Overhead camshaft · Connecting rod · Crank · Crank substitute · Crankshaft · Scotch Yoke · Swashplate · Rhombic driveOtherCategories:- Piston engine configurations

- Napier Deltic

- Napier engines

- Piston ported engines

- Diesel locomotive engines

- Marine diesel engines

- Two-stroke diesel engines

- Opposed piston engines

- Diesel engines by model

Wikimedia Foundation. 2010.