- Insulated glazing

-

Insulated glazing (IG) also known as double glazing are double or triple glass window panes separated by an air or other gas filled space to reduce heat transfer across a part of the building envelope.

Glass in windows is used to provide light and allow a view from either side to the other side. While the composition and manufacturing of glass is covered elsewhere, for the purposes of this article, its importance to the construction is its dimensional stability over a wide temperature range.

Insulated Glass Units (IGUs) are manufactured with glass in range of thickness from 3 mm to 10 mm or more in special applications. Laminated or tempered glass may also be used as part of the construction. Most units are manufactured with the same thickness of glass used on both panes[citation needed] but special applications such as acoustic attenuation or security may require wide ranges of thicknesses to be incorporated in the same unit.

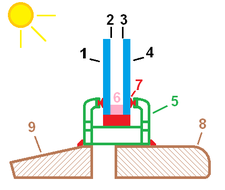

A sectioned diagram of a fixed Insulated Glazed Unit (IGU), indicating the numbering convention used in this article. Surface #1 is facing outside, Surface #2 is the inside surface of the exterior pane, Surface #3 is the outside surface of the interior pane, and Surface #4 is the inside surface of interior pane. The window frame is labelled #5, a spacer is indicated as #6, seals are shown in red (#7), the internal reveal is on the right hand side (#8) and the exterior windowsill on the left (#9)

A sectioned diagram of a fixed Insulated Glazed Unit (IGU), indicating the numbering convention used in this article. Surface #1 is facing outside, Surface #2 is the inside surface of the exterior pane, Surface #3 is the outside surface of the interior pane, and Surface #4 is the inside surface of interior pane. The window frame is labelled #5, a spacer is indicated as #6, seals are shown in red (#7), the internal reveal is on the right hand side (#8) and the exterior windowsill on the left (#9)

To reduce shear effects on the sealed unit (a major cause of premature failure), manufacturers use a rule of thumb that permits a difference of 1 mm between the thickness of the panes of glass used in the unit and still maintain the warranty for the unit.[citation needed] For example, a unit may be ordered with a 4 mm pane on the exterior and a 3 mm pane on the interior. These variations are allowed for architectural and cost reasons. Other combinations can be specified and produced but the manufacturer may reserve the right to limit the term of the warranty or refuse to warranty the unit altogether.

For ease of description the surfaces of a double paned unit are named according to the following convention: Surface #1 (facing outside), Surface #2 (inside of outside pane), Surface #3 (outside of inside pane) and Surface #4 (inside surface of inside pane). Applying the corresponding nomenclature for triple paned units results in surfaces #1 through #6.

The performance of insulating glazing can be modified through the use of the following:

Contents

Spacer

The glass panes are separated by a "spacer". A spacer is the piece that separates the two panes of glass in an insulating glass system, and seals the gas space between them. Historically, spacers were made primarily of metal, which manufacturers thought provided more durability.

However, metal spacers conduct heat (unless the metal is thermally improved), undermining the ability of the IGU to reduce heat flow. It may also result in water or ice forming at the bottom of the sealed unit because of the sharp temperature difference between the window and surrounding air. To reduce heat transfer through the spacer and increase overall thermal performance, manufactures may make the spacer out of a less-conductive material such as structural foam.[1] A spacer made of aluminum that also contains a highly structural thermal barrier reduces condensation on the glass surface and improves insulation, as measured by the overall U-factor (see Thermal conductivity).

- A spacer that reduces heat flow in glazing configurations may also have characteristics for sound dampening in urban areas subjected to irritating noise levels, such as near subways, trucks and airports.[2]

- Typically, spacers are filled with or contain desiccant to remove moisture trapped in the gas space during manufacturing, thereby lowering the dew point of the gas in that space, and preventing condensation from forming on surface #2 when the outside glass pane temperature falls.

- New technology has emerged to combat the heat loss from traditional spacer bars, including improvements to the structural performance and long-term-durability of improved metal (aluminum with a thermal barrier) and foam spacers.

Construction

IGUs are manufactured on a made to order basis on factory production lines. The width and height dimensions, the thickness of the glass panes and the type of glass for each pane as well as the overall thickness of the unit must be supplied to the manufacturer. On the assembly line, spacers of specific thicknesses are cut and assembled into the required overall width and height dimensions and filled with desiccant. On a parallel line, glass panes are cut to size and washed to be optically clear.

An adhesive sealant (polyisobutylene - PIB) is applied to the face of the spacer on each side and the panes pressed against the spacer. If the unit is gas filled, two holes are drilled into the spacer of the assembled unit, lines are attached to draw out the air out of the space and replacing it with the desired gas. The lines are then removed and holes sealed to contain the gas. The more modern technique is to use an online gas filler, which eliminates the need to drill holes in the spacer. The units are then sealed on the edge side using either polysulphide or silicone sealant or similar material to prevent humid outside air from entering the unit. The desiccant will remove traces of humidity from the air space so that no water appears on the inside faces of the glass panes facing the air space during cold weather. Some manufacturers have developed specific processes that combine the spacer and desiccant into a single step application system.[3]

The double glazed window was invented in 1930s, and was commonly available in USA in the 1950s under the ThermopaneTM brand name, registered in 1941 by Libbey-Owens-Ford Glass Company.[4] After so many decades, the manufacturing process is well established. The brand name Thermopane has entered the vocabulary of the glazing industry as the genericized trademark for any IGU.

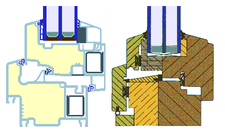

Materials which can be used for double glazing are versatile and include aluminum, PVC, and wood (timber).[5]

Thermal performance

The maximum insulating efficiency of a standard IGU is determined by the thickness of the space containing the gas or vacuum. Too little space between the panes of glass results in conductive heat loss between the panes (the inside surface of one pane cools the surface of the other pane) while too wide a gap results in convection current losses (gas begins to circulate because of temperature differences and transfers heat between the panes). For further information, see the article heat flow. Typically, most sealed units achieve maximum insulating values using a gas space of between 5/8 to 3/4” (16–19 mm) when measured at the centre of the IGU. When combined with the thickness of the glass panes being used, this can result in an overall thickness of the IGU of between 7/8 and 1” for 3 mm glass (22–25 mm) to 1½” (28–31 mm ) for 1/4” plate glass.

IGU thickness is a compromise between maximizing insulating value and the ability of the framing system used to carry the unit. Some residential and most commercial glazing systems can accommodate the ideal thickness of a double paned unit. Issues arise with the use of triple glazing to further reduce heat loss in an IGU. The combination of thickness and weight results in units that are too unwieldy for most residential or commercial glazing systems, particularly if these panes are contained in moving frames or sashes.

These issues can be solved in various ways. A product known as Vacuum Insulated Glass (VIG), or evacuated glazing, can be used to drastically reduce heat loss due to convection and conduction.[6] These VIG units have most of the air removed from the space between the panes, leaving a nearly-complete vacuum. VIG units which are currently on the market are hermetically sealed along their perimeter with solder glass, that is, a glass frit having a reduced melting point. Such a glass seal is rigid, and will experience increasing stress as the outer pane temperature rises or falls relative to that of the inner pane. Rigid seal glazing is generally restricted to applications for which the temperature differential across the VIG will NOT exceed 35 °C (63 °F), such as warmer climates where air conditioning costs are significant but temperature differentials remain within the warranted range.[7]

Vacuum technology is also used in some non-transparent insulation products called vacuum insulated panels.

A more practical alternative is to replace air in the space with a heavy gas that is more viscous than oxygen and nitrogen. Higher viscosity reduces convective heat transfer, as well as reducing the heat capacity portion coming from rotational degrees of freedom. Argon (argon has a thermal conductivity 67% that of air),[8] krypton (krypton has about half the conductivity of argon) or xenon (about 1/3 the conductivity of argon) is used to increase the insulating performance. Some manufacturers also offer sulfur hexafluoride as an insulating gas, especially to insulate sound. It has only 2/3 the conductivity of argon, but it is stable, inexpensive and dense.[9] Krypton and Xenon are very expensive. These gases are used because they are non-toxic, clear, odorless, chemically inert, and commercially available because of their widespread application in industry. These gases have a higher density compared to air but have higher costs.

In general, the more effective a fill gas is at its optimum thickness, the thinner the optimum thickness is. For example, the optimum thickness for krypton is lower than for argon, and lower for argon than for air.[10] However, since it is difficult to determine whether the gas in an IGU has become mixed with air at time of manufacture (or becomes mixed with air once installed), many designers prefer to use thicker gaps than would be optimum for the fill gas if it were pure. Argon is commonly used in insulated glazing as it is the most affordable. Krypton, which is considerably more expensive, is not generally used except to produce very thin double glazing units or relatively thin, or extremely high performance triple glazed units.[11] Xenon has found very little application in IGUs because of cost.[12]

Heat insulating properties

The effectiveness of insulated glass can be expressed as an R-value. The higher the R-value, the greater is its resistance to heat transfer. A standard IGU consisting of clear uncoated panes of glass (or lites) with air in the cavity between the lites typically has an R-value of 0.35 K·m2/W (2 h·ft2·°F/BTU).

Using imperial units, a rule of thumb in standard IGU construction is that each change in the component of the IGU results in an increase of 1 R-value to the efficiency of the unit. Adding Argon gas increases the efficiency to about R-3. Using low emissivity glass on surface #2 will add another R-value. Properly designed triple glazed IGUs with low emissivity coatings on surfaces #2 and #4 and filled with argon gas in the cavities result in IG units with R-values as high as R-5. Certain vacuum insulated glass units (VIG) or multi-chambered IG units using coated plastic films result in R-values as high as R-12.5[11]

Acoustic insulating properties

In some situations the insulation is in reference to noise mitigation. In these circumstances a large air space improves the noise insulation quality or Sound transmission class. Asymmetric double glazing, using different thicknesses of glass rather than the conventional symmetrical systems (equal glass thicknesses used for both lites) will improve the acoustic attenuation properties of the IGU. If standard air spaces are used, sulfur hexafluoride is used to replace or augment an inert gas[13] and improve acoustical attenuation performance.

Other glazing material variations affect acoustics. The most widely used glazing configurations for sound dampening include laminated glass with varied thickness of the interlayer and thickness of the glass. Including a structural, thermally improved aluminum thermal barrier air spacer in the insulating glass can improve acoustical performance by reducing the transmission of exterior noise sources in the fenestration system.

Reviewing the glazing system components, including the air space material used in the insulating glass, can ensure overall sound transmission improvement.[14]

Longevity

The life of an IGU varies depending on the quality of materials used, size of gap between inner and outer pane, temperature differences, workmanship and location of installation both in terms of facing direction and geographic location. IG units typically last from 10 to 25 years, with windows facing south (Northern Hemisphere) or the north (Southern Hemisphere) often lasting less than 12 years. IGUs typically carry a warranty for 10 to 20 years depending upon the manufacturer. If IGUs are altered (such as installation of a solar control film) the warranty may be voided by the manufacturer.

The Insulating Glass Manufacturers Alliance (IGMA)[15] undertook an extensive study to characterize the failures of commercial insulating glass units over a 25-year period.[16]

For a standard construction IG unit, condensation collects between the layers of glass when the perimeter seal has failed and when the desiccant has become saturated, and can only be eliminated by replacing the IGU. Seal failure and subsequent replacement results in a significant factor in the overall cost of owning IGUs.

Large temperature differences between the inner and outer panes stresses the spacer adhesives, which can eventually fail. Units with a small gap between the panes are more prone to failure because of the increased stress.

Atmospheric pressure changes combined with wet weather can, in rare cases, eventually lead to the gap filling with water.

In Canada, since the beginning of 1990, there are some companies offering restoration of failed IG units. They provide open ventilation to the atmosphere by drilling hole(s) in the glass and/or spacer. This solution often reverses the visible condensation, but cannot clean the interior surface of the glass and staining that may have occurred after long term exposure to moisture. They may offer a warranty from 5 to 20 years. This solution lowers the value of the glass a bit, but it can be a "green" solution when the window is still in good condition. If the IG unit had a gas fill (e.g. argon or krypton or a mixture) the gas is naturally dissipated and the R-value suffers.

Since 2004, there are also some companies offering the same restoration process for failed double glazed units in the UK, and there is one company offering restoration of failed IG units in Ireland since 2010.

Estimating heat loss from double glazed window

Estimating the rate of heat loss is essential in choosing which type of double glazed window to be used in a building to maintain desired thermal comfort. Relevant data and calculation from different calculations are listed below: Beware that heat loss due to radiation is not taken into account!

Required data

To properly estimate the heat loss through any window, one needs to take into account not only the pane and gap, but also the thermal properties of sash, frame and sill. Thermal bridging through any of these can lead to huge energy losses. It is better[citation needed] to make calculations using the overall window performance values rather than just that at the glass center.

- Thermal resistance of the glass used

- Physical properties of the gas used in between the gap (such as density, heat capacity and k value)

- Dimension of the double glazed glass

Calculation

Table 1.1 Relevant correlations to calculate natural convection inside the window gap[17]

Condition Correlation

By using natural convection correlations that fulfil the given criteria; the overall heat transfer coefficient can be calculated by using equation (1). Hence, to estimate the overall heat loss, equation (2) will be used

_______(1)

_______(1) _______(2)

_______(2)Example calculation of heat loss from double glazed window

Q. Estimate the heat transfer coefficient and thermal resistance of the air gap in a double glazed window. Assume that the outer surface of the inner glass pane is at 10 °C and that the inner surface of the outer glass pane is at -10 °C. Assume that the window is 2m tall (H) and 2 m wide, and that the gap between the glass panes is 1.5 cm (L). How does the thermal resistance compare to glass 0.003 m2K/W and curtains ~0.5 m2K/W? If air is a good insulator, why is such a small air gap used?

Physical property of air

μ 1.65 × 10−5 Pa s Cp 1050 J/kg K k 0.0242 W/m K Solution

First calculate

,

,  ,

,  and

and  to determine which natural convection correlation to use.

to determine which natural convection correlation to use.

133.33

6.67 × 104

1.10 × 104

6.94 × 10−1 Therefore, the best correlation that fulfill the calculated condition is

We then proceed to calculate the heat transfer coefficient of the gas in between the glass. Be reminded that the

We then proceed to calculate the heat transfer coefficient of the gas in between the glass. Be reminded that the  is the width of the gap and the

is the width of the gap and the  is the height of the window. Calculating the Nusselt number will yield 1.11 and further calculating will yield 'h' value of 1.80 W/m^2 K.

is the height of the window. Calculating the Nusselt number will yield 1.11 and further calculating will yield 'h' value of 1.80 W/m^2 K.

Since we've known the thermal resistance value of each glass, we can proceed to calculate the overall heat transfer coefficient of the double glazed window by using equation 2.To calculate the overall heat loss, equation 2 is used.

See also

- Curtain wall

- G-value

- Glass

- Passive solar design

- Window

References

- ^ "Edgetech I.G., Does the spacer really matter?". Superspacer.com. http://www.superspacer.com/Homeowners/SuperSpacer.aspx?section=homeowners. Retrieved 2011-04-05.

- ^ "Glazing configurations for improved thermal efficiency and sound dampening". Warmedge.com. http://warmedge.com/index.php/lang-en/technology/acoustic-performance.html. Retrieved 2011-04-05.

- ^ tremcoeurope.com

- ^ [1]

- ^ "Double Glazing | Double Glazing Windows & Doors | Double Glazing Perth | Casver - Timber Double Glazing". Casverwindowsystems.com.au. http://casverwindowsystems.com.au/Timber-Double-Glazing. Retrieved 2011-04-05.

- ^ "Development and quality control of vacuum glazing by N. Ng and L. So; University of Sydney". Glassfiles.com. http://www.glassfiles.com/library/article.php?id=1174&search=evacuated&page=1. Retrieved 2011-04-05.

- ^ "Warranty,Precaution | Nippon Sheet Glass Spacia Co.,Ltd". Nsg-spacia.co.jp. 1991-10-20. http://www.nsg-spacia.co.jp/tech/warranty.html. Retrieved 2011-04-05.

- ^ "Energy Rated Double Glazing Windows from". Conservatory Outlet. http://www.conservatoryoutlet.co.uk/energy-rated-replacement-windows/argon-filled. Retrieved 2011-04-05.

- ^ Barth & Aleixo SF6 Insulated Glass Panes

- ^ ASHRAE Handbook, Volume 1, Fundamentals, 1993

- ^ a b "Southwall Technologies: Heat Mirror Insulating Glass". Southwall.com. http://www.southwall.com/southwall/Home/Products/Residential/HeatMirrorInsulatingGlass.html. Retrieved 2011-04-05.

- ^ http://www.ktu.lt/ultra/journal/pdf_51_2/51-2004-Vol.2_01-J.Butkus.pdf

- ^ "Sound insulation - Google Books". Books.google.com. http://books.google.com/books?id=bqUxCGJd0owC&pg=PA504&lpg=PA504&dq=hexafluoride+insulating+glass&source=web&ots=niJxrJZMBa&sig=DQwDhsPWasPns4IgA4tJtyR_YXs&hl=en&sa=X&oi=book_result&resnum=1&ct=result. Retrieved 2011-04-05.

- ^ "Acoustic performance and glazing system components". Warmedge.com. http://warmedge.com/index.php/lang-en/technology/acoustic-performance.html. Retrieved 2011-04-05.

- ^ "IGMA". Igmaonline.org. http://www.igmaonline.org. Retrieved 2011-04-05.

- ^ "Powered by Google Docs". Docs.google.com. http://docs.google.com/viewer?a=v&q=cache%3AuJBE0li3Xd4J%3Awww.ornl.gov%2Fsci%2Fbuildings%2F2010%2FSession%2520PDFs%2F66_New.pdf+25+year+field+correlation+study+IG&hl=en&gl=us&sig=AHIEtbRkQ77HMBM0XQFqhczDrEgcPZE8HQ&pli=1. Retrieved 2011-04-05.

- ^ Kavanagh.J, 'Heat Transfer, Natural Convection' March 2008, Department Of Chemical Engineering, University of Sydney.

- Handbook of Chemistry & Physics & Double Glazing, 62ed, CRC Press, ISBN-0-8493-0462-8

External links

-

Glass science topics Basics Glass formulation - AgInSbTe

- Bioglass

- Borophosphosilicate glass

- Borosilicate glass

- Ceramic glaze

- Chalcogenide glass

- Cobalt glass

- Cranberry glass

- Crown glass

- Flint glass

- Fluorosilicate glass

- Fused quartz

- GeSbTe

- Gold ruby glass

- Lead glass

- Milk glass

- Phosphosilicate glass

- Photochromic lens glass

- Silicate glass

- Soda-lime glass

- Sodium hexametaphosphate

- Soluble glass

- Tellurite glass

- Ultra low expansion glass

- Uranium glass

- Vitreous enamel

- Wood's glass

- ZBLAN

Glass-ceramics Glass preparation Optics - Achromat

- Dispersion

- Gradient index optics

- Hydrogen darkening

- Optical amplifier

- Optical fiber

- Optical lens design

- Photochromic lens

- Photosensitive glass

- Refraction

- Transparent materials

Surface modification Diverse topics

Categories:- Energy conservation

- Windows

- Building engineering

- Building materials

- Glass coating and surface modification

- Glass applications

- Low-energy building

- Insulators

- Thermal protection

- Heat transfer

Wikimedia Foundation. 2010.