- Vespel

-

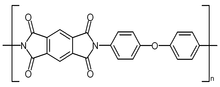

Structure of a Vespel polymer

Structure of a Vespel polymer

Vespel is the trademark of a range of durable high-performance polyimide-based plastics manufactured by DuPont. The one shown in the structure on the right was the first to be commercialized.[1]

Contents

Characteristics and applications

This high performance polymer is mostly used in aerospace, semiconductor and transportation technology. It combines heat resistance, lubricity, dimensional stability, chemical resistance, and creep resistance, to be used in hostile and extreme environmental conditions.

Unlike most plastics, it does not produce significant outgassing even at high temperatures, which makes it useful for lightweight heat shields and crucible support. It also performs well in vacuum applications, down to extremely low cryogenic temperatures. However, Vespel tends to absorb a small amount of water, resulting in longer pump time while placed in a vacuum.

Although there are polymers surpassing polyimide in all of these properties, the combination of them is the main advantage of Vespel.

Thermophysical properties

Vespel is commonly used as a thermal conductivity reference material for testing thermal insulators, because of high reproducibility and consistency of its thermophysical properties. For example, it can withstand repeated heating up to 300 °C without altering its thermal and mechanical properties.[2] Extensive tables of measured thermal diffusivity, specific heat capacity, and derived density, all as functions of temperature, have been published.[2]

Magnetic properties

Vespel is used in high-resolution probes for NMR spectroscopy because its volume magnetic susceptibility (−(9.02 ± 0.25)×10−6 for Vespel SP-1 at 21.8 °C[3]) is close to that of water at room temperature (−9.03×10−6 at 20 °C [4] Negative values indicate that both substances are diamagnetic. Matching volume magnetic susceptibilities of materials surrounding NMR sample to that of the solvent can reduce susceptibility broadening of magnetic resonance lines.

Processing for manufacturing applications

Vespel can be processed by direct forming (DF) and isostatic molding (basic shapes – plates, rods and tubes). For prototype quantities, basic shapes are typically used for cost efficiency since tooling is quite expensive for DF parts. For large scale CNC production, DF parts are often used to reduce per part costs, at the expense of material properties which are inferior to those of isostatically produced basic shapes.

Types

For different applications, special formulations are blended / compounded. Some examples of standard polyimide compounds are:

- virgin polyimide

- provides operating temperatures from cryogenic to 300 °C (570 °F), high plasma resistance, as well as a UL rating for minimal electrical and thermal conductivity. This is the unfilled base polyimide resin. It also provides high physical strength and maximal elongation, and the best electrical and thermal insulation values. Examples of products under this category are Vespel SP-1, VTEC PI and Meldin 7001.

- 15% graphite by weight

- added to the base resin for increased wear resistance and reduced friction in applications such as plain bearings, thrust washers, seal rings, slide blocks and other wear applications. This compound has the best mechanical properties of the graphite-filled grades, but lower than the virgin grade. Examples of products under this category are Vespel SP-21, VTEC BG21 and Meldin 7021.

- 40% graphite by weight

- for enhanced wear resistance, lower friction, improved dimensional stability (low coefficient of thermal expansion), and stability against oxidation. Examples: Vespel SP-22, VTEC BG22 and Meldin 7022.

- 10% PTFE and 15% graphite by weight

- added to the base resin for the lowest coefficient of friction over a wide range of operating conditions. It also has excellent wear resistance up to 149 °C (300 °F). Typical applications include sliding or linear bearings as well as many wear and friction uses listed above. Trade names are Vespel SP-211, VTEC BG211 and Meldin 7211.

- 15% moly-filled (molybdenum disulfide solid lubricant)

- for wear and friction resistance in vacuum and other moisture-free environments where graphite actually becomes abrasive. Typical applications include seals, plain bearings, gears, and other wear surfaces in outer space, ultra-high vacuum or dry gas applications. Typical trade names found for this grade are Vespel SP-3, VTEC BG3 and Meldin 7003.

Material properties data

Material properties of Vespel[5] (produced by isostatic molding + machining) Property Units Test condition SP-1 SP-21 SP-22 SP-211 SP-3 Filler material unfilled 15% graphite 40% graphite 10% PTFE, 15% graphite 15% molybdenum disulfide specific gravity dimensionless 1.43 1.51 1.65 1.55 1.60 thermal expansion coefficient 10−6/K 211–296 K 45 34 296–573 K 54 49 38 54 52 thermal conductivity W/mK at 313 K 0.35 0.87 1.73 0.76 0.47 volume resistivity Ω m at 296 K 1014–1015 1012–1013 dielectric constant dimensionless at 100 Hz 3.62 13.53 at 10 kHz 3.64 13.28 at 1 MHz 3.55 13.41 References

- ^ DuPont Science of Vespel

- ^ a b Jacobs-Fedore, R. A.; Stroe, D. E. (2004). "Thermophysical properties of Vespel SP1". In Wang, Hsin; Porter, Wallace D.; Porter, Wally. Thermal Conductivity 27/Thermal Expansion 15. Knoxville, TN: DEStech Publications, Inc.. pp. 231–238. ISBN 1-9320-7834-7. http://destechpub.com/pageview.asp?PageID=16095.

- ^ P. T. Keyser and S. R. Jefferts (1989). "Magnetic Susceptibility of Some Materials Used for Apparatus Construction (at 295 K)". Rev. Sci. Instrum. 60 (8): 2711–2714. doi:10.1063/1.1140646.

- ^ A. Carlsson, G. Starck, M. Ljungberg, S. Ekholm and E. Forssell-Aronsson (2006). "Accurate and sensitive measurements of magnetic susceptibility using echo planar imaging". Magn. Reson. Imaging 24 (9): 1179–1185. doi:10.1016/j.mri.2006.07.005. PMID 17071340.

- ^ Summary of typical properties standard SP polyimide resins. DuPont

Categories:- Plastics

- DuPont products

Wikimedia Foundation. 2010.