- Microscanner

-

A microscanner (or micro-scanning mirror) is a micro-opto-electromechanical system (MOEMS) in the category of micro-mirror actuators for dynamic light modulation. Depending upon the type of microscanner the modulatory movement of a single mirror can be either translatory or rotational, on one or two axes. In the first case, a phase shifting effect takes place. In the second case, the incident light wave is deflected.

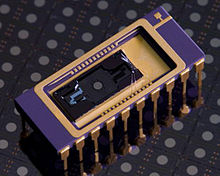

Resonant translational mirror in pantograph design with a deflection of ±500 µm

Resonant translational mirror in pantograph design with a deflection of ±500 µm

Therefore, they have to be differentiated from spatial light modulators, other micro-mirror actuators which need a matrix of individually addressable mirrors for their mode of operation. If a single array mirror already fulfils the desired modulation but is operated in parallel with other array mirrors in order to increase the light yield, then the term microscanner array is used.

Contents

Characteristics

Common chip dimensions are 4 mm × 5 mm for mirror diameters between 1 and 3 mm[1]. However larger mirror apertures with side measurements of up to approx. 10 mm × 3 mm can also be produced.[2] The scan frequencies depend upon the design and mirror size and range between 0.1 and 50 kHz. The deflection movement is either periodic or quasi-static. With microsanners that are capable of tilting movement, light can be directed over a projection plane. Depending on the mirror's scan trajectory the surface is raster scanned with a specific pattern. For double resonant operation, which results in sinusoidal scan motion, a Lissajous pattern is written. Mechanical deflection angles of such micro scanning devices reach up to ±30°.[3] With translational (piston type) microscanners a mechanical stroke of up to approx. ±500 µm can be attained.[4]

Drive principles

The required drive forces for the mirror movement can be provided by various physical principles. In practice, the relevant principles for driving such a mirror are the electromagnetic, electrostatic, thermo-electric and piezo-electric effects.

Because the physical principles differ in their advantages and disadvantages, a suitable driving principle should be chosen according to the application. Electromagnetic drives provide a high driving force, however the high level of power consumption is disadvantageous for mobile applications. Furthermore, the necessary high magnetic field intensity is only attainable in combination with external permanent magnets, so that the ability to miniaturize the microscanner is limited.

Electrostatic actuators offer high power similar to electromagnetic drives, yet consume 2 – 3 magnitude orders less power. In contrast to an electromagnetic drive, the resulting drive force between the drive structures cannot be reversed in polarity. For the realization of quasi-static components with positive and negative effective direction, two drives with positive and negative polarity are required. As a rule of thumb, vertical comb drives are utilized here. Nevertheless the highly non-linear drive characteristics in some parts of the deflection area can be hindering for controlling the mirror properly. For that reason many highly developed microscanners today utilize a resonant mode of operation, where an Eigenmode is activated. Resonant operation is most energy efficient. For beam positioning and applications which are to be static-actuated or linearized-scanned, quasi-static drives are required and therefore of great interest.

Thermoelectric drives produce high driving forces, but they present a few technical drawbacks inherent to their fundamental principle. The actuator has to be thermally well insulated from the environment, as well as being pre-heated in order to prevent thermal drift due to environmental influences. That is why the necessary heat output and power consumption for a thermal bimorph actuator is relatively high. One further disadvantage is the comparably low displacement which needs to be leveraged to reach useable mechanical deflections. Also thermal actuators are not suitable for high frequency operation due to significant low pass behaviour.

Piezo-electrical drives also produce small deflections in comparison to electromagnetic and electrostatic drives, so they share the disadvantages of electro-thermal actuators in this regard. They are, however, less susceptible to thermal environmental influences and can also transmit high-frequency drive signals well.

Fields of Application

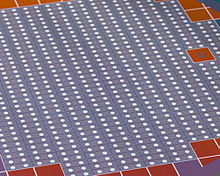

MEMS scanner module for 3D distance measurement (LIDAR) with a single sending mirror (mirror dimensions approx. (9.5 × 2.5 mm)) and a synchronized microscanner array (2 × 7) as receiver unit.

MEMS scanner module for 3D distance measurement (LIDAR) with a single sending mirror (mirror dimensions approx. (9.5 × 2.5 mm)) and a synchronized microscanner array (2 × 7) as receiver unit.

Applications for tilting microscanners are numerous and include:

- Projection displays[5][6]

- Image recording, e.g. for technical and medical endoscopes[3]

- Bar code scanning [7]

- Spectroscopy

- Laser marking and material processing

- Object measurement / triangulation[2]

- 3D cameras

- Object recognition

- 1D and 2D light grid

- Confocal microscopy / OCT

- Fluorescence microscopy

- Laser wavelength modulation

Some of the applications for piston type microscanners are:

- Fourier transform infrared spectrometer

- Confocal microscopy

- Focus variation

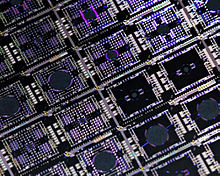

Manufacture

Microscanners are usually manufactured with surface or bulk micromechanic processes. As a rule, silicon or BSOI (bonded silicon on insulator) are used.

Advantages and disadvantages of microscanners

The advantages of microscanners compared to macroscopic light modulators such as galvanometer scanners are based upon their small size, low weight and minimum power consumption. Further advantages arise along with the integration possibilities of position sensor technology [8] and electronics in the component. Microscanners are also extremely resistant to environmental influences. For example, the microscanners developed at Fraunhofer IPMS have a shock resistance of at least 2500 g. Under the condition that they are sealed free from dust and humidity, they are maintenance-free and operate at temperatures between -20 °C and +80 °C.

Some of the disadvantages due to the manufacturing process are high costs for single devices and long delivery times. In order to address these problems, scientists at Fraunhofer IPMS provide a platform technology – a MEMS modular system called VarioS® – which reduces this problem to a minimum.

References

- ^ VarioS®Mikroscanner Construction Kit. Fraunhofer Institute for Photonic Microsystems IPMS (Product Description).

- ^ a b Sandner, T.; Grasshoff, T.; Wildenhain, M.; Schenk, H. (2010). "Synchronized micro scanner array for large aperture receiver optics of LIDAR systems". Proc. SPIE 7594 – MOEMS and Miniaturized Systems IX: 75940C. doi:10.1117/12.844923.

- ^ a b Drabe, C.; James, R.; Schenk, H.; Sandner, T. (2010). "MEMS-Devices for Laser Camera Systems for Endoscopic Applications". Proc. SPIE 7594 – MOEMS and Miniaturized Systems IX: 759404. doi:10.1117/12.846855.

- ^ Sandner, T.; Grasshoff, T.; Schenk, H.; Kenda, A. (2011). "Out-Of-Plane Translatory MEMS actuator with extraordinary large stroke for optical path length modulation". Proc. SPIE 7930 – MOEMS and Miniaturized Systems X: 79300I. doi:10.1117/12.879069.

- ^ Yalcinkaya, Arda D.; Urey, Hakan; Brown, Dean; Montague, Tom; Sprague, Randy (2006). "Two-Axis Electromagnetic Microscanner for High Resolution Displays". Journal of Microelectromechanical Systems 15 (4): 786–794. doi:10.1109/JMEMS.2006.879380.

- ^ Scholles, Michael; Bräuer, Andreas; Frommhagen, Klaus; Gerwig, Christian; Lakner, Hubert; Schenk, Harald; Schwarzenberg, Markus (2008). "Ultracompact laser projection systems based on two-dimensional resonant microscanning mirrors". Journal of Micro/Nanolithography, MEMS and MOEMS 7 (2): 021001. doi:10.1117/1.2911643.

- ^ Wolter, A.; Schenk, H.; Gaumont, E.; Lakner, H. (2004). "MEMS microscanning mirror for barcode reading: from development to production". Proc. SPIE 5348 – MOEMS Display and Imaging Systems II: 32–39. doi:10.1117/12.530795.

- ^ Grahmann, J.; Grasshoff, T.; Conrad, H.; Sandner, T.; Schenk, H. (2011). "Integrated piezoresistive position detection for electrostatic driven micro scanning mirrors". Proc. SPIE 7930 – MOEMS and Miniaturized Systems X: 79300V. doi:10.1117/12.874979.

External links

- MEMS Scanners. Fraunhofer Institute for Photonic Microsystems

- ARI MEMS Micromirror Demonstration Devices. Adriatic Research Institute

- Getting Started with Analog Mirrors. Texas Instruments (Product Page)

Categories:- Microtechnology

- Microelectronic and microelectromechanical systems

Wikimedia Foundation. 2010.