- Welding defect

-

A welding defect is any flaw that compromises the usefulness of the finished weldment.

According to the American Society of Mechanical Engineers (ASME) welding defect causes are broken down into the following percentages: 41% poor process conditions, 32% operator error, 12% wrong technique, 10% incorrect consumables, and 5% bad weld grooves.[1]

Contents

Major causes

Hydrogen embrittlement

Residual stresses

The magnitude of stress that can be formed from welding can be roughly calculated using:[2]

- EαΔT

Where E is Young's modulus, α is the coefficient of thermal expansion, and ΔT is the temperature change. For steel this calculates out to be approximately 3.5 GPa (510,000 psi).

Types

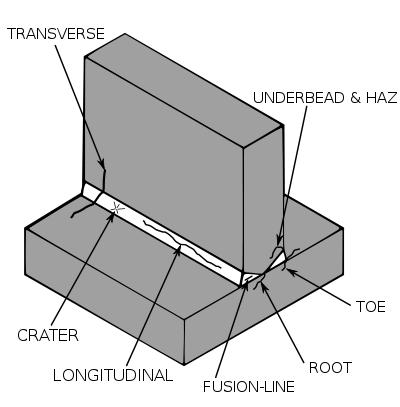

Cracks

Defects related to fracture.

Arc strike cracking

Arc strike cracking occurs when the arc is struck but the spot is not welded. This occurs because the spot is heated above the materials upper critical temperature and then essentially quenched. This forms martensite, which is brittle, and micro-cracks. Usually the arc is struck in the weld groove so this type of crack does not occur, but if the arc is struck outside of the weld groove then it must be welded over to prevent the cracking. If this is not an option then the arc spot can be postheated, i.e., the area is heated with an oxy-acetylene torch, and then allowed to cool slowly.[3]

Cold cracking

Residual stresses can reduce the strength of the base material, and can lead to catastrophic failure through cold cracking, as in the case of several of the Liberty ships. Cold cracking is limited to steels, and is associated with the formation of martensite as the weld cools. The cracking occurs in the heat-affected zone of the base material. To reduce the amount of distortion and residual stresses, the amount of heat input should be limited, and the welding sequence used should not be from one end directly to the other, but rather in segments.[4]

Cold cracking only occurs when all the following preconditions are met:[citation needed]

- susceptible microstructure (e.g. martensite)

- hydrogen present in the microstructure (hydrogen embrittlement)

- service temperature environment (normal atmospheric pressure): -100 to +100 °F

- high restraint

Eliminating any one of these will eliminate this condition.

Crater crack

Crater cracks occur when a crater is not filled before the arc is broken. This causes the outer edges of the crater to cool more quickly than the crater, which creates sufficient stresses to form a crack. It may form a longitudinal or transverse crack or form multiple radial cracks.[5]

Fusion-line crack

Hat crack

Hat cracks get their name from the shape of the cross-section of the weld, because the weld flares out at the face of the weld. The crack starts at the fusion line and extends up through the weld. They are usually caused by too much voltage or not enough speed.[5]

Hot cracking

Hot cracking, also known as solidification cracking, can occur with all metals, and happens in the fusion zone of a weld. To diminish the probability of this type of cracking, excess material restraint should be avoided, and a proper filler material should be utilized.[4] Other causes include too high welding current, poor joint design that does not diffuse heat, impurities (such as sulfur and phosphorus), preheating, speed is too fast, and long arcs.[6]

Underbead crack

An underbead crack, also known as a heat-affected zone (HAZ) crack,[7] is a crack that forms a short distance away from the fusion line; it occurs in low alloy and high alloy steel. The exact causes of this type of crack are not completely understood, but it is known that dissolved hydrogen must be present. The other factor that affects this type of crack is internal stresses resulting from: unequal contraction between the base metal and the weld metal, restraint of the base metal, stresses from the formation of martensite, and stresses from the precipitation of hydrogen out of the metal.[8]

Longitudinal crack

Longitudinal cracks run along the length of a weld bead. There are three types: check cracks, root cracks, and full centerline cracks. Check cracks are visible from the surface and extend partially into weld. They are usually caused by high shrinkage stresses, especially on final passes, or by a hot cracking mechanism. Root cracks start at the root and extent part way into the weld. They are the most common type of longitudinal crack because of the small size of the first weld bead. If this type of crack is not addressed then it will usually propagate into subsequent weld passes, which is how full centerline cracks (a crack from the root to the surface) usually form.[5]

Reheat cracking

Reheat cracking is a type of cracking that occurs in HSLA steels, particularly chromium, molybdenum and vanadium steels, during postheating. It is caused by the poor creep ductility of the heat affected zone. Any existing defects or notches aggravate crack formation. Things that help prevent reheat cracking include heat treating first with a low temperature soak and then with a rapid heating to high temperatures, grinding or peening the weld toes, and using a two layer welding technique to refine the HAZ grain structure.[9][10]

Root and toe cracks

Transverse crack

Distortion

Welding methods that involve the melting of metal at the site of the joint necessarily are prone to shrinkage as the heated metal cools. Shrinkage then introduces residual stresses and distortion. Distortion can pose a major problem, since the final product is not the desired shape. To alleviate certain types of distortion the workpieces can be offset so that after welding the product is the correct shape.[11] The following pictures describe various types of welding distortion:[12]

Gas inclusion

Gas inclusions is a wide variety of defects that includes porosity, blow holes, and pipes (or wormholes). The underlying cause for gas inclusions is the entrapment of gas within the solidified weld. Gas formation can be from any of the following causes: high sulfur content in the workpiece or electrode, excessive moisture from the electrode or workpiece, too short of an arc, or wrong welding current or polarity.[7]

Inclusions

There are two types of inclusions: linear inclusions and isolated inclusions. Linear inclusions occur when there is slag or flux in the weld. Slag forms from the use of a flux, which is why this type of defect usually occurs in welding processes that use flux, such as shielded metal arc welding, flux-cored arc welding, and submerged arc welding, but it can also occur in gas metal arc welding. This defect usually occurs in welds that require multiple passes and there is poor overlap between the welds. The poor overlap does not allow the slag from the previous weld to melt out and rise to the top of the new weld bead. It can also occur if the previous weld left and undercut or an uneven surface profile. To prevent slag inclusions the slag should be cleaned from the weld bead between passes via grinding, wire brushing, or chipping.[13]

Isolated inclusions occur when rust or mill scale is present on the base metal.[14]

Lack of fusion and incomplete penetration

Lack of fusion is the poor adhesion of the weld bead to the base metal; incomplete penetration is a weld bead that does not start at the root of the weld groove. Incomplete penetration forms channels and crevices in the root of the weld which can cause serious issues in pipes because corrosive substances can settle in these areas. These types of defects occur when the welding procedures are not adhered to; possible causes include the current setting, arc length, electrode angle, and electrode manipulation.[15]

Lamellar tearing

Lamellar tearing is a type of welding defect that occurs in rolled steel plates.[16] It has rarely been an issue since the 1970s because steel produced since then has less sulfur.[17]

There is a combination of causes: non-metallic inclusions, too much hydrogen in the material, and shrinkage forces perpendicular to the face of the plates. The main factor among these reasons is the non-metal inclusions, of which the sulfur is the main problem. Lamellar tearing is no longer a problem anymore because sulfur levels are typical kept below 0.005%.[17]

Some things that are done to overcome lamellar tearing are: reducing amount of sulfur in the material or adding alloying elements that control the shape of sulfide inclusions, such as rare earth elements, zirconium, or calcium.[18] A more drastic option is change the workpieces to castings or forgings because this type of defect does not occur in those workpieces.[16]

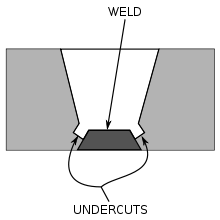

Undercut

Undercutting is when the weld reduces the cross-sectional thickness of the base metal, which reduces the strength of the weld and workpieces. One reason for this type of defect is excessive current, causing the edges of the joint to melt and drain into the weld; this leaves a drain-like impression along the length of the weld. Another reason is if a poor technique is used that does not deposit enough filler metal along the edges of the weld. A third reason is using an incorrect filler metal, because it will create greater temperature gradients between the center of the weld and the edges. Other causes include too small of an electrode angle, a dampened electrode, excessive arc length, and slow speed.[19]

References

- ^ Matthews, Clifford (2001), ASME engineer's data book, ASME Press, p. 211, ISBN 9780791801550, http://books.google.com/books?id=7nIqrfROowQC&pg=PA211.

- ^ Bull, Steve (2000-03-16), Magnitude of stresses generated, University of Newcastle upon Tyne, archived from the original on 2009-12-06, http://www.webcitation.org/5lpLTHRZo, retrieved 2009-12-06.

- ^ Rampaul 2003, pp. 207–208.

- ^ a b Cary & Helzer 2005, pp. 404–405.

- ^ a b c Raj, Jayakumar & Thavasimuthu 2002, p. 128.

- ^ Bull, Steve (2000-03-16), Factors promoting hot cracking, University of Newcastle upon Tyne, archived from the original on 2009-12-06, http://www.webcitation.org/5lpX2E1S7, retrieved 2009-12-06.

- ^ a b Raj, Jayakumar & Thavasimuthu 2002, p. 126.

- ^ Rampaul 2003, p. 208.

- ^ Bull, Steve (2000-03-16), Reheat cracking, University of Newcastle upon Tyne, archived from the original on 2009-12-06, http://www.webcitation.org/5lpXkrGfA, retrieved 2009-12-06.

- ^ Bull, Steve (2000-03-16), Reheat cracking, University of Newcastle upon Tyne, archived from the original on 2009-12-06, http://www.webcitation.org/5lpYdb66E, retrieved 2009-12-06.

- ^ Weman 2003, pp. 7–8.

- ^ Bull, Steve (2000-03-16), Welding Faults and Defects, University of Newcastle upon Tyne, archived from the original on 2009-12-06, http://www.webcitation.org/5lpDLc6Iw, retrieved 2009-12-06.

- ^ Defects/imperfections in welds - slag inclusions, archived from the original on 2009-12-05, http://www.webcitation.org/5lp4O9zyW, retrieved 2009-12-05.

- ^ Bull, Steve (2000-03-16), Welding Faults and Defects, University of Newcastle upon Tyne, archived from the original on 2009-12-05, http://www.webcitation.org/5lnmtLCCy.

- ^ Rampaul 2003, p. 216.

- ^ a b Bull, Steve (2000-03-16), Welding Faults and Defects, University of Newcastle upon Tyne, archived from the original on 2009-12-03, http://www.webcitation.org/5ll21lW3L.

- ^ a b Still, J. R., Understanding Hydrogen Failures, http://www.aws.org/wj/jan04/still_feature.html, retrieved 2009-12-03.

- ^ Ginzburg, Vladimir B.; Ballas, Robert (2000), Flat rolling fundamentals, CRC Press, p. 142, ISBN 9780824788940, http://books.google.com/books?id=NeKG76F4KWUC&pg=PA141.

- ^ Rampaul 2003, pp. 211–212.

Bibliography

- Cary, Howard B.; Helzer, Scott C. (2005), Modern Welding Technology, Upper Saddle River, New Jersey: Pearson Education, ISBN 0-13-113029-3.

- Raj, Baldev; Jayakumar, T.; Thavasimuthu, M. (2002), Practical non-destructive testing (2nd ed.), Woodhead Publishing, ISBN 9781855736009, http://books.google.com/books?id=qXcCKsL2IMUC.

- Rampaul, Hoobasar (2003), Pipe welding procedures (2nd ed.), Industrial Press, ISBN 9780831131418, http://books.google.com/books?id=cie00sSLFqoC.

- Weman, Klas (2003), Welding processes handbook, New York, NY: CRC Press, ISBN 0-8493-1773-8.

External links

Categories:

Wikimedia Foundation. 2010.