- Induction cooker

-

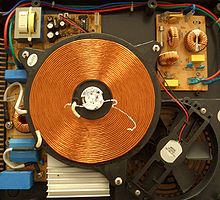

Inside an induction stove showing the litz wire coil.

An induction cooker uses induction heating for cooking. Unlike other forms of cooking, heat is generated directly in the pot or pan (cooking vessel), as opposed to being generated in the stovetop by electrical coils or burning gas. To be used on an induction cooker, a cooking vessel must be made of a ferromagnetic metal.

In an induction cooker, a coil of copper wire is placed underneath the cooking pot. An alternating electric current flows through the coil, which produces an oscillating magnetic field. This field induces an electric current in the pot. Current flowing in the metal pot produces resistive heating which heats the food. While the current is large, it is produced by a low voltage.

An induction cooker is faster and more energy-efficient than a traditional electric hob. It allows instant control of cooking energy similar to gas burners. Because induction heats the cooking vessel itself, the possibility of burn injury is significantly less than with other methods; the surface of the cook top is only heated from contact with the vessel. There are no flames or red-hot electric heating elements as found in traditional cooking equipment. The induction effect does not heat the air around the vessel, resulting in further energy efficiencies; some air is blown through the cooktop to cool the electronics, but this air emerges only a little warmer than ambient temperature.

Induced current can heat any type of metal, but the magnetic properties of a steel vessel concentrate the induced current in a thin layer near the surface, which makes the heating effect stronger. In non-magnetic materials like aluminum, the magnetic field penetrates too far, and the induced current encounters little resistance in the metal. Practical induction cookers are designed for ferromagnetic pots that will stick to a magnet. [1]

Since heat is being generated by an induced electric current, the unit can detect whether cookware is present (or whether its contents have boiled dry) by monitoring how much power is being absorbed. That allows such functions as keeping a pot at minimal boil or automatically turning an element off when cookware is removed from it.

Contents

Benefits

This form of flameless cooking has certain advantages over conventional gas flame and electric cookers, as it provides rapid heating, improved thermal efficiency, and greater heat consistency, yet with precise control similar to gas.[2] In situations in which a hotplate would typically be dangerous or illegal, an induction plate is ideal, as it creates no heat itself.

The high efficiency of power transfer into the cooking vessel makes heating food faster on an induction cooktop than on other electric cooktops. Because of the high efficiency, an induction element has heating performance comparable to a typical consumer-type gas element, even though the gas burner would have a much higher power input. [3]

Induction cookers are safer to use than conventional cookers because there are no open flames. The surface below the cooking vessel is no hotter than the vessel; only the pan generates heat. Induction cookers are easy to clean because the cooking surface is flat and smooth, even though it may have several heating zones. Since the cooking surface is not directly heated, spilled food does not burn on the surface.

Because the cook top is shallow compared to a gas-fired or electrical coil cooktop, wheelchair access can be improved; the user's legs can be below the counter height and the user's arms can reach over the top.[4]

Limitations

Cookware must be compatible with induction heating; glass and ceramics are unusable, as are solid copper or solid aluminum cookware. Cookware must have a flat bottom since the magnetic field drops rapidly with distance from the surface. (Special and costly hobs are available for use with round-bottom woks.) Induction rings are a metal plate that heat up a non-ferrous pot by contact, but these sacrifice much of the power and efficiency of direct use of induction in a compatible cooking vessel.

Manufacturers advise consumers that the glass ceramic top can be damaged by impact, although cooktops are required to meet minimal product safety standards for impact. [5] Aluminum foil can melt onto the top and cause permanent damage or cracking of the top.

A small amount of noise is generated by an internal cooling fan. Audible noise (a hum or buzz) may be produced by cookware exposed to high magnetic fields, especially at high power or if the cookware has loose parts. Some users may detect a whistle or whine sound from the cookware, or from the power electronic devices. Some cooking techniques available when cooking over a flame are not applicable. Persons with implanted cardiac pacemakers or other electronic medical implants may be advised by their doctors to avoid proximity to induction cooktops and other sources of magnetic fields.[4] Radio receivers near the unit may pick up some electromagnetic interference.

Economic and environmental considerations

According to the U.S. Department of Energy, the efficiency of energy transfer for an induction hob is 84%, versus 74% for a smooth-top non-induction electrical unit, for an approximate 10% saving in energy for the same amount of heat transfer.[6]

Energy efficiency is the ratio between energy delivered to the food and that consumed by the cooker, considered from the "customer side" of the energy meter. Cooking with gas has an energy efficiency of about 40% at the customer's meter (energy purchased vs. energy deposited into the food) and can be raised only by using very special pots[7], so the DOE efficiency value will be used.

When comparing consumption of energies of different kinds, in this case natural gas and electricity, the correct method enforced by the US Environmental Protection Agency is to resort to source (also called primary) energies. They are the energies of the raw fuels that are really consumed to produce the energies delivered on site.[8] The conversion to source energies is done by multiplying site energies by appropriate source-site ratios. Unless there are knowledge and good reasons to use custom source-site ratios (for example for non US residents), EPA states that "it is most equitable to employ national-level ratios".[9] These ratios amount to 3.34 for electricity purchased from the grid, and 1.047 for natural gas. This latter figure is slightly greater than 1 and mainly accounts for distribution losses. The energy efficiencies for cooking given above (84% for induction and 40% for gas) are in terms of site energies at the customer's meters. The (US averaged) efficiencies recalculated relative to source fuels energies are hence 25% for induction hobs, and 38% for gas hobs.

Source-site ratios are not formalized yet in Western Europe. A common consensus should arise on unified European ratios in view of the extension of the Energy Label to domestic water heaters. Unofficial figures for European source-site ratios are about 2.2 for electricity and 1.02 for natural gas, thus giving overall (referred to source energy) efficiencies of 38% for induction hobs and 39% for gas hobs. These provisional figures need to be somehow adjusted due to the higher gas hob efficiency, allowed in Europe by a less stringent limit on carbon monoxide emission at the hob.

Whenever local electricity emits less than 435 grams of CO2 per kWh, the greenhouse effect of an induction cooker will be lower than that of a gas cooker. This again comes from the relative efficiencies (84% and 40%) of the two hobs and from the standard 200 (±5) grams CO2/kWh emission factor for combustion of natural gas at its net (low) calorific value.

Common usage

Induction equipment may be a built-in hob, part of a range, or a standalone hob unit. Built-in and rangetop units typically have multiple elements, the equivalent of separate burners on a gas-fueled range. Stand-alone induction "modules" are usually single-element, or sometimes have dual elements. All such elements share a basic design: an electromagnet sealed beneath a heat-resisting glass-ceramic sheet that is easily cleaned. The pot is placed on the ceramic glass surface and begins to heat up, along with its contents.

In Japan, some models of rice cookers are powered by induction. In Hong Kong, power companies list a number of models.[10] Asian manufacturers have taken the lead in producing inexpensive single-induction-zone hobs; efficient, low-waste-heat units are advantageous in densely populated cities with little living space per family, as many Asian cities are. Induction cookers are less frequently used in other parts of the world.

Induction ranges may be applicable in commercial restaurant kitchens. Electric cooking avoids the cost of natural gas piping and in some jurisdictions may allow simpler ventilation and fire suppression equipment to be installed.[11] Drawbacks for commercial use include higher initial cost and the requirement for magnetic cookware.

Heat generation

An induction cooker transfers electrical energy by induction from a coil of wire into a pot made of material which must be electrically conductive and ferromagnetic. The heat generated is analogous to the unwanted heat dissipated in an electric transformer; most of the heat is due to resistive heating like a transformer's copper losses and eddy currents and the rest is analogous to a transformer's other iron losses.

A coil of wire is mounted under the cooking surface, and a large alternating current is passed through it. The current creates a changing magnetic field. When an electrically conductive pot is brought close to the cooking surface, the magnetic field induces an electrical current, called an "eddy current", in the pot. The eddy current, flowing through the electrical resistance, causes electrical power to be dissipated as heat; the pot gets hot and heats its contents by heat conduction.

The cooking surface is made of a glass-ceramic material which is a poor heat conductor, so only minimal heat is transferred from the pot to the cooking surface (and thus wasted). In normal operation the cooking surface stays cool enough to touch without injury after the cooking vessel is removed.

Some energy will be dissipated wastefully by the current flowing through the resistance of the coil; wasted energy is minimised by the geometry of the design and by the coil having low resistance. The cooking vessel is typically made from stainless steel or iron. Since the increased magnetic permeability of the material decreases the skin depth, the resistance will be further increased. The copper coil, on the other hand, is made from wire known as litz wire, which is a bundle of many smaller insulated wires in parallel. The coil has many turns, while the bottom of the pot effectively forms a single shorted turn. This forms a transformer that steps down the voltage and steps up the current. The resistance of the pot, as viewed from the primary coil, appears larger. That, in turn, means that most of the energy becomes heat in the high-resistance steel, while the driving coil stays cool.

The reason aluminium or copper does not work on an induction cooktop is because of the materials' permeability and resistivity.[12] Aluminium or copper cookware is more conductive than steel, and the skin depth in these materials is larger since they are nonmagnetic. The current flows in a thicker layer in the metal and so encounters less resistance and produces less heat. The induction cooker will not work efficiently with such pots.

The heat that can be produced in a pot is a function of the surface resistance. A higher surface resistance produces more heat for similar currents. This is a "figure of merit" that can be used to rank the suitability of a material for induction heating. The surface resistance in a thick metal conductor is proportional to the resistivity divided by the skin depth. Where the thickness is less than the skin depth, the actual thickness can be used to calculate surface resistance.[12] Some common materials are listed in this table.

Skin depth at 24 kHz [12] Material Resistivity

(10^-6 ohm-inches)Relative

permeabilitySkin depth,

inchesSurface resistance,

10^-3 ohms/squareRelative to copper 1010 carbon steel 9 200 0.004 2.25 56.25 432 Stainless steel 24.5 200 0.007 3.5 87.5 304 Stainless steel 29 1 0.112 0.26 6.5 Aluminum 1.12 1 0.022 0.051 1.28 Copper 0.68 1 0.017 0.04 1 Obtaining the same surface resistance with materials such as copper would require them to be much thinner than is practical for a cooking vessel; a copper vessel bottom would be 1/56th the thickness of the carbon steel pot.[12] Since the skin depth is inversely proportional to the square root of the frequency, this suggests that much higher frequencies (say, several megahertz) would be required to obtain equivalent heating in a copper pot as in an iron pot at 25 kHz. Such high frequencies are not feasible with inexpensive semiconductors; in 1973 the silicon-controlled rectifiers used were limited to no more than 40 kHz.[12] Even a thin layer of copper on the bottom of a steel cooking vessel will shield the steel from the magnetic field and make it unusable for an induction top.[12]

Some additional heat is created by hysteresis losses in the pot due to its ferromagnetic nature, but this creates less than ten percent of the total heat generated.[13] [14]

Early production

An early induction cooker patent from 1909 illustrates the principle. The coil of wire S induces a magnetic field in the magnetic core M. The magnetic field passes through the bottom of the pot A, inducing eddy currents within it. Unlike this concept, a modern cooktop uses electronically-generated high-frequency current.

An early induction cooker patent from 1909 illustrates the principle. The coil of wire S induces a magnetic field in the magnetic core M. The magnetic field passes through the bottom of the pot A, inducing eddy currents within it. Unlike this concept, a modern cooktop uses electronically-generated high-frequency current.

First patents date from the early 1900s.[15] Demonstration stoves were shown by the Frigidaire division of General Motors in the mid-1950s[16] on a touring GM showcase in North America. The induction cooker was shown heating a pot of water with a newspaper placed between the stove and the pot, to demonstrate the convenience and safety. This unit, however, was never put into production.

Modern implementation in the USA dates from the early 1970s, with work done at the Research & Development Center of Westinghouse Electric Corporation at Churchill Borough, near Pittsburgh, PA, USA.[12] That work was first put on public display at the 1971 National Association of Home Builders convention in Houston, Texas, as part of the Westinghouse Consumer Products Division display.[citation needed] The stand-alone single-burner range was named the Cool Top Induction Range. It used paralleled Delco Electronics transistors developed for automotive electronic ignition systems to drive the 25 kHz current.

Westinghouse decided to make a few hundred production units to develop the market. Those were named Cool Top 2 (CT2) Induction ranges. The development work was done at the same R&D location, by a team led by Bill Moreland and Terry Malarkey. The ranges were $1,500. That price included a set of high quality cookware made of Quadraply, a stainless steel/carbon steel/aluminium/stainless steel laminate (outside to inside).

Production took place in 1973 through to 1975 and stopped, coincidentally, with the sale of Westinghouse Consumer Products Division to White Consolidated Industries Inc.

CT2 had four burners of about 1,600 watts each. The range top was a PyroCeram ceramic sheet surrounded by a stainless-steel bezel, upon which four magnetic sliders adjusted four corresponding potentiometers set below. That design, using no through-holes, made the range proof against spills. The electronic section was made in four identical modules cooled by fans.

In each of the electronics modules, the 240V, 60 Hz domestic line power was converted to between 20V to 200V of continuously variable DC by a phase-controlled rectifier. That DC power was in turn converted to 27 kHz 30 A (peak) AC by two arrays of six paralleled Motorola automotive-ignition transistors in a half-bridge configuration driving a series-resonant LC oscillator, of which the inductor component was the induction-heating coil and its load, the cooking pan. That elegant circuit design, largely by Ray Mackenzie [17], successfully dealt with certain bothersome overload problems.

Control electronics included functions such as protection against over-heated cook-pans and overloads. Provision was made to reduce radiated electrical and magnetic fields. [18] [19] There was also magnetic pan detection. [20]

CT2 was UL Listed and received Federal Communications Commission (FCC) approval, both firsts. Numerous patents were also issued. CT2 won several awards, including Industrial Research Magazine's IR-100 1972 best-product award and a citation from the United States Steel Association. Raymond Baxter demonstrated the CT2 on his BBC series, Tomorrow’s World. He showed how the CT2 could cook through a slab of ice.

Sears Kenmore sold a free-standing oven/stove with four induction-cooking surfaces in the mid-1980s (Model Number 103.9647910). The unit also featured a self-cleaning oven, solid-state kitchen timer and capacitive-touch control buttons (advanced for its time). The units were more expensive than standard cooktops.

Vendors

The market for induction stoves is dominated by German manufacturers, such as AEG, Bosch, Fissler, Miele and Siemens. The Spanish company Fagor, Italian firm Smeg and Sweden's Electrolux are also key players in the European market. Prices range from about GBP250 to 1,000 within the UK. In 2006, Stoves launched the UK's first domestic induction hob (cooktop) on a range cooker at a slightly lower cost than those imported.

The European induction cooking market for hotels, restaurants and other caterers is primarily satisfied by smaller specialist commercial induction catering equipment manufacturers such as Adventys of France, Control Induction and Target Catering Equipment of the UK and Scholl of Germany.

Taiwanese and Japanese electronics companies are the dominant players in induction cooking for East Asia. After aggressive promotions by utilities in HK like Power HK Ltd, many local brands like UNIVERSAL, icMagIC, Zanussi, iLighting, German Pool also emerged. Their power and ratings are high, more than 2,800 watts. They are multiple zone and capable of performing better than their gas counterpart. The efficiency is as high as 90% and saves a lot of energy and is environmentally friendly. Their use by local Chinese for wok cooking is becoming popular. Some of these companies have also started marketing in the West. However, the product range sold in Western markets is a subset of that in their domestic market; some Japanese electronics manufacturers only sell domestically.

Small stand-alone induction cookers are relatively inexpensive, priced from around US$20.

Units may have two, three, four or five induction zones, but four (normally in a 30-inch-wide unit) is the most common in the US and Europe. Two coils are most common in Hong Kong and three are most common in Japan. Some have touch-sensitive controls. Some induction stoves have a memory setting, one per element, to control the time that heat is applied.

Cookware considerations

The cookware that can be used on an induction hob will be generally the same as those that can be used on a conventional electric or gas hob. Some manufacturers mark the cookware or packagaging with symbols to indicate compatibility with induction, gas, or electric heat. Induction hobs (cooktops) work well with any pans with a high ferrous metal content at the base. Cast iron pans and any black metal or iron pans will work on an induction hob. Stainless steel pans will often work on an induction hob provided the sole of the pan is a grade of stainless steel that is magnetic. If a magnet sticks well to the sole of the pan, it will work on an induction hob.

For frying on an induction hob, a pan with a base that is a good heat conductor is needed to spread the heat quickly and evenly. The sole of the pan will be either a steel plate pressed into the aluminium, or a layer of stainless steel over the aluminium. The high thermal conductivity of aluminium pans makes the temperature more uniform across the pan. Stainless frying pans with an aluminium base will not have the same temperature at their sides as an aluminium sided pan will have. Cast iron frying pans work well with induction hobs but the material is not as good a thermal conductor as aluminum.

When boiling water, the water spreads the heat and prevents hot spots. For products such as sauces, it is important that at least the base of the pan incorporates a good heat conducting material such as aluminium to spread the heat evenly across the base. For really delicate products such as thick sauces, a pan with aluminium throughout is better, since the heat flows up the sides through the aluminium, allowing the chef to heat the sauce rapidly but evenly.

See also

References

- ^ Llorente, S.; Monterde, F.; Burdio, J.M.; Acero, J. (2002). "A comparative study of resonant inverter topologies used in induction cookers". http://ieeexplore.ieee.org/iel5/7757/21322/00989392.pdf?arnumber=989392. Retrieved 2009-05-20.

- ^ http://theinductionsite.com/proandcon.shtml

- ^ http://theinductionsite.com/how-induction-works.shtml#HOWMUCH retrieved 2011 Sept 9

- ^ a b http://theinductionsite.com/proandcon.shtml Induction site, pro and con list , retrieved 2011 01 06

- ^ Hans Bach, Dieter Krause, Low thermal expansion glass ceramics, Springer, 2005 ISBN 3540241116 page 77, lists IEC, UL, Canadian, Australian and other standards with impact resistance requirements

- ^ Technical support document for residential cooking products. Volume 2: Potential impact of alternative efficiency levels for residential cooking products. (see Table 1.7). U.S. Department of Energy, Office of Codes and Standards.

- ^ Greg Sorensen; David Zabrowski (August 2009). "Improving Range-Top Efficiency with Specialized Vessels". Appliance Magazine. http://www.appliancemagazine.com/editorial.php?article=2257&zone=114&first=1. Retrieved 2010-08-07.

- ^ Understanding Source and Site Energy : ENERGY STAR. Retrieved 18 November 2011

- ^ Energy Star (March 2011). "Methodology for Incorporating Source Energy Use". http://www.energystar.gov/ia/business/evaluate_performance/site_source.pdf.

- ^ http://www.heh.com/hehWeb/ElectricLiving/ElectricalAppliancesInformation/DomesticAppliances/ElectricCooker/InductionCooker_en.htm Honk Kong Electric company Web site on household appliances, retrieved 2011 Feb 21

- ^ Roger Fields, Restaurant Success by the Numbers: A Money-Guy's Guide to Opening the Next Hot Spot, Random House of Canada, 2007 ISBN 1580086632, pp.144-145

- ^ a b c d e f g , W. C.Moreland, The Induction Range: Its Performance and Its Development Problems, IEEE Transactions on Industry Applications, vol. TA-9, no. 1, January/February 1973 pages 81-86

- ^ Fairchild Semiconductors (2000-07). "AN9012 Induction Heating System Topology Review". http://www.fairchildsemi.com/an/AN/AN-9012.pdf. Retrieved 2009-05-20.

- ^ Renesas Technology Europe (2008). "Induction cooking Basics". http://eu.renesas.com/media/applications/consumer_industrial/induction_cooking/Renesas_Induction_Cooking.pdf. Retrieved 2009-05-20.

- ^ see e.g. UK Patent Application GB190612333, entitled "Improvements in or relating to Apparatus for the Electrical Production of Heat for Cooking and other purposes", applied for by Arthur F. Berry on 26 May 1906 and accepted on 25 May 1907

- ^ Kitchen of the Future has Glass-Dome Oven and Automatic Food Mixer, Popular Mechanics Apr 1956, page 88

- ^ US Patent 3889090 "Induction Heat Cooking Apparatus", Raymond W Mackenzie

- ^ US Patent 4163139 "Cooking vessel capacitive decoupling for induction cooking apparatus", Terence D Malarkey et al

- ^ US Patent 3996442 "Induction heating coil assembly for heating cooking vessels", William C Moreland II et al

- ^ US Patent 3796850 "Pan detector for induction heating cooking unit", William C Moreland II et al

External links

- Technical Support Document for Residential Cooking Products

- Video demonstrating how an induction cooktop works

Categories:- Cooking appliances

- Electromagnetic components

Wikimedia Foundation. 2010.