- Monsanto process

-

The Monsanto process is an important method for the manufacture of acetic acid by catalytic carbonylation of methanol. This process operates at a pressure of 30–60 atm and a temperature of 150–200 °C and gives a selectivity greater than 99%. It was developed 1960 by German BASF and improved by Monsanto in 1966, which introduced a new catalyst system.[1] The Monsanto process has largely been supplanted by the Cativa process, a similar iridium-based process developed by BP Chemicals Ltd which is more economical and environmentally friendly.

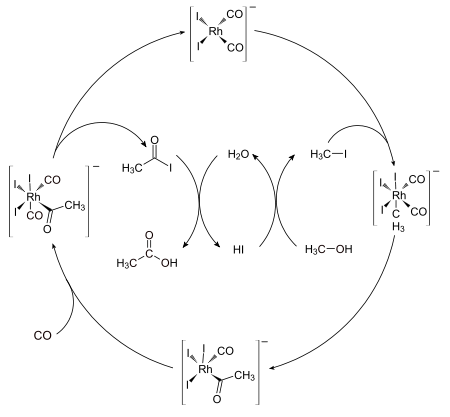

Catalytic cycle

The catalytically active species is the anion cis-[Rh(CO)2I2]− (1). The catalytic cycle has been shown to involve six steps, two of which do not involve rhodium: conversion of methanol to methyl iodide and the hydrolysis of the acetyl iodide to acetic acid. The first organometallic step is the oxidative addition of methyl iodide to cis-[Rh(CO)2I2]− to form the hexacoordinate species [(CH3)Rh(CO)2I3]− (2). This anion rapidly transforms, via the migration of a methyl group to the carbonyl ligand, affording the pentacoordinate acetyl complex [(CH3CO)Rh(CO)I3]− (3). This five-coordinate complex then reacts with carbon monoxide to form the six coordinate dicarbonyl complex (4) which decomposes by reductive elimination to form acetyl iodide (CH3COI) and regenerate the active form of the catalyst. Acetyl iodide is then hydrolyzed to acetic acid.[2]

The reaction has been shown to be first-order with respect to methyl iodide and the catalyst (1). Hence the rate-determining step of the catalytic cycle has been proposed to be the oxidative addition of methyl iodide to the catalyst (1). It is believed that this occurs via the nucleophilic attack by the rhodium centre on the carbon of methyl iodide.

Tennessee Eastman acetic anhydride process

Acetic anhydride is produced by carbonylation of methyl acetate in a process that was inspired by the Monsanto acetic acid synthesis.[3]

- CH3CO2CH3 + CO → (CH3CO)2O

In this process lithium iodide converts methyl acetate to lithium acetate and methyl iodide, which in turn affords through carbonylation acetyl iodide. Acetyl iodide reacts with acetate salts or acetic acid to give the product. Rhodium iodides and lithium salts are employed as catalysts. Because acetic anhydride is not stable in water, the conversion is conducted under anhydrous conditions in contrast to the Monsanto acetic acid synthesis.

References

- ^ http://www.greener-industry.org.uk/pages/ethanoicAcid/6ethanoicAcidPM2.htm

- ^ Jones, J. H. (2000). "The CativaTM Process for the Manufacture of Acetic Acid". Platinum Metals Rev. 44 (3): 94–105. http://www.platinummetalsreview.com/pdf/pmr-v44-i3-094-105.pdf.

- ^ Zoeller, J. R.; Agreda, V. H.; Cook, S. L.; Lafferty, N. L.; Polichnowski, S. W.; Pond, D. M. (1992). "Eastman Chemical Company Acetic Anhydride Process". Catalysis Today 13 (1): 73–91. doi:10.1016/0920-5861(92)80188-S.

- http://www.uyseg.org/catalysis/ethacid/ethacid2.htm

- http://www.uyseg.org/greener_industry/pages/ethanoicAcid/6ethanoicAcidPM2.htm

Principles Reactions Types of compounds Applications Related branches of chemistry Categories:- Organometallic chemistry

- Rhodium

- Catalysis

- Chemical processes

Wikimedia Foundation. 2010.