- Navajo Generating Station

-

Navajo Generating Station

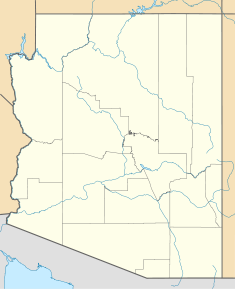

Navajo Generating StationLocation of Navajo Generating Station Country United States Location Navajo Nation, near Page, Arizona Coordinates 36°54′12″N 111°23′25″W / 36.90333°N 111.39028°WCoordinates: 36°54′12″N 111°23′25″W / 36.90333°N 111.39028°W Commission date 1974, 1975, 1976 Owner(s) U.S. Bureau of Reclamation (24.3%)

Salt River Project (21.7%)

Los Angeles Dept. of Water and Power (21.2%)

Arizona Public Service (14.0%)

NV Energy (11.3%)

Tucson Electric Power (7.5%)Operator(s) Salt River Project Power station information Primary fuel Coal Generation units 3[1] Power generation information Installed capacity 2250 MW[2] Navajo Generating Station is a 2250 megawatt coal-fired powerplant located on the Navajo Indian Reservation, near Page, Arizona, USA. This plant provides electrical power to customers in Arizona, Nevada, and California. It also provides the power for pumping Colorado River water for the Central Arizona Project, supplying about 1.5 million acre feet (1.85 km3) of water annually to central and southern Arizona.

Contents

History

In the 1950’s and 1960’s, there was a need for new electric generation in the Southwest to supply power to growing populations in southern California, Arizona and Nevada. The US Bureau of Reclamation also needed a large source of power for running the pumps of the planned Central Arizona Project (CAP).

A number of power projects were initially considered to fill these needs, most notably Bridge Canyon and Marble Canyon hydroelectric dams on the Colorado River. However, the proximity of the proposed dams to the Grand Canyon raised opposition, initially from the National Park Service and then more vigorously from a coalition of environmental groups which promoted construction of a thermal or nuclear power plant as an alternative. [3] As a result, the proposed dams were abandoned in favor of the Navajo Power Project, consisting of the Navajo Generating Station along with the Kayenta mine, BM&LP railroad, and 800 miles (1,300 km) of 500 KV transmission lines.

The site selected for the new power plant was about six miles (10 km) east of Glen Canyon Dam and three miles (5 km) south of Lake Powell on 1,786 acres (7.23 km2) of land leased from the Navajo Nation. The site was close to a source of competitively priced fuel and a reliable source of surface water for cooling. The nearby city of Page and U.S. Highway 89 provided existing infrastructure to support construction and operation of the project. The contract for engineering and construction was awarded to Bechtel Corporation, which began construction on the site in April, 1970.[4] Generating units 1, 2, and 3 were completed in 1974, 1975, and 1976 respectively at a total cost of about $650 million.

Between 1977 and 1990, following Clean Air Act amendments for assessing and protecting visibility in national parks and wilderness areas, the EPA, Salt River Project and other entities cooperated in visibility studies to assess possible effects that NGS emissions might have on those areas.

The series of studies culminated in the Winter Haze Intensive Tracer Experiment (WHITEX) and the Navajo Generating Station Visibility Study (NGSVS). Those studies indicated that controlling SO2 emissions might improve winter visual range in the Grand Canyon by 2% to 7%, which prompted the EPA to propose a rule requiring NGS to reduce SO2 emissions by 70%.

NGS and environmental groups, however, negotiated an approach that would achieve a greater degree of improvement at lower cost. They agreed to, and recommended a requirement of a 90% reduction in SO2 emissions based on an annual average, with installation to be completed in 1999. The EPA accepted the recommendation and implemented those conditions in its final rule.[5]

The technology selected for flue gas desulfurization was wet SO2 scrubbing with forced oxidation. Stone & Webster, the architect-engineering firm for the scrubber project, began construction in 1994 and completed the work on Units 3, 2, and 1 in 1997, 1998, and 1999 respectively.[6] The cost of the scrubber project was about $420 million.

In 2007, a BART analysis was conducted for nitrogen oxide (NOx) emissions, prompted by Clean Air Act regional haze regulations. The analysis concluded that Low NOx burners with separated overfire air (SOFA) would provide the best available retrofit technology alternative in accordance with EPA BART guidelines.[7] Consequently, low NOx burners with SOFA were added to units 3, 2, and 1 during eight-week outages in February through March of 2009, 2010, and 2011 respectively.

Design and Specifications

The plant has three identical 750 MW steam electric generating units. Major components of each unit include a boiler, turbine, generator, closed-cycle cooling system, and environmental control equipment.

The boilers are tangentially fired, balanced draft, reheat type steam generators, supplied by Combustion Engineering. Designed for supercritical operation, they supply steam to the turbines at 3500 psi (241 bar) and 1000 °F (537 °C).

The main turbines are General Electric (GE) tandem compound reheat turbines, each directly coupled to a generator and designed to rotate at 3600 rpm.

Steam discharged from the turbines enters a condenser where water circulating through tubes cools and condenses it, producing a vacuum that maximizes the pressure drop across the turbine. The heat picked up by the circulating water is removed by evaporation in six induced-draft cross flow cooling towers (two per unit). The plant uses up to 28,000 acre feet (35,000,000 m3) of water per year from Lake Powell, or about 1/2 gallon (1.9L) per kWh, mainly for cooling water and scrubber operation.[8]

The plant consumes about 8 million tons of low sulfur bituminous coal each year, supplied by Peabody Energy’s Kayenta mine near Kayenta, Arizona. The coal is hauled 75 miles from mine silos to the plant by the Black Mesa and Lake Powell electric railroad. Characteristics of the coal in 2010 included a sulfur content of 0.62%, an ash content of 10.4%, and higher heating value (HHV) of 10,820 Btu/lb.[9]

The plant has three 775 ft (236 meter) tall flue gas stacks, listed among the tallest structures in Arizona. The stacks were constructed of reinforced concrete, supporting an internal metal liner. The plant's original stacks were demolished in the late 1990's after being replaced by larger diameter stacks of the same height, resulting in the plant having six stacks visible for a time.

The new stacks were required to accommodate cooler flue gas saturated with water vapor that resulted when wet SO2 scrubbers were added.Performance

Annual net generation: 17,136,152 Megawatt-hours

Net capacity factor: 87%

Net heat rate: 10,112 Btu/ kWh.[9]

Environmental Controls

Particulate

Hot side electrostatic precipitators (ESP’s), constructed as part of the original plant, remove 99% of particulate from the flue gas. The SO2 scrubbers remove an additional 50% of particulate remaining in the flue gas after passing through the ESP’s.

Flue-gas desulfurization

Each unit has a forced oxidation wet scrubber for flue-gas desulfurization, using limestone slurry in two countercurrent–flow absorber vessels to remove 92% of SO2 from the flue gas. The three scrubbers in total consume about 24 MW of power, and use 130,000 tons of limestone and 3,000 acre·ft (3,700,000 m3) of water per year, producing 200,000 tons of gypsum per year.

Nitrogen oxide

Low NOx burners with separated overfire air used to control nitrogen oxide emissions.

Emissions summary

Component Rate (lb/mmBtu) Rate (lb/MWh) Annual plant total (tons/year) SO2 0.471 4,076 NOx 0.21 2.385 20,633 CO2 2,295 19,859,041 Wastewater handling

NGS was built with one of the first zero liquid discharge (ZLD) systems in a power plant, recovering all cooling tower blow-down and runoff from developed areas of the site. The waste water is processed through three brine concentrators and a crystallizer, which remove the solids and produce distilled water for re-use within the plant. [11] Several lined ponds are used in conjunction with the ZLD system to capture and regulate the flow of waste water to the system.

Byproducts handling

The plant sells about 500,000 tons of fly ash per year for use in the manufacture of concrete and Flexcrete insulating block building product.[12] Bottom ash and gypsum, a byproduct of the scrubber operation, are dewatered in the removal process; and, along with any fly ash not sold, are landfilled on-site as solids. No wet impoundments are used for ash or byproduct disposal.

References

- ^ "Existing Electric Generating Units in the United States, 2007" (Excel). Energy Information Administration, U.S. Department of Energy. 2007. http://www.eia.doe.gov/cneaf/electricity/page/capacity/capacity.html. Retrieved 2009-07-09.

- ^ "Navajo Generating Station". SRP.

- ^ Jennifer E. Zuniga (2000). "The Central Arizona Project". Bureau of Reclamation History Program. U.S. Bureau of Reclamation. http://www.usbr.gov/projects//ImageServer?imgName=Doc_1303158888395.pdf. Retrieved 2011-06-01.

- ^ "Chapter I. Introduction and History of the Navajo Project". Environmental Planning for the Navajo Generating Station Status Report. Prepared by Bechtel Corporation, The Navajo Project. 1970. pp. 1 - 3. OCLC 4711442.

- ^ Mike Sundblom, Arizona Department of Environmental Quality. "RA BART (Reasonably Attributable Best Available Retrofit Technology) Case Study, Navajo Generating Station, Appendix C". Western Regional Air Partnership. http://www.wrapair.org/forums/amc/projects/ra_bart_case/Navajo-C.doc. Retrieved 2011-08-22.

- ^ "Part 71 Federal Operating Permit Statement of Basis – Navajo Generating Station, Permit No. NN-ROP-05-06". Navajo Nation Environmental Protection Agency. 2006. p. 2. http://www.navajonationepa.org/airqty/Pdf_files/NGS_sob052708.pdf. Retrieved 2011-08-27.

- ^ ENSR Corporation - AECOM (2007). "BART Analysis for the Navajo Generating Station Units 1 - 3". Western Regional Air Partnership. pp. 6-1 & 6-2. http://www.wrapair.org/forums/ssjf/documents/bart/2007-11_SRP_Navajo_BART_Analysis_Report.pdf. Retrieved 2011-08-27.

- ^ "Navajo Generating Station Water Intake Project Environmental Assessment". 2005. p. 34. OCLC 282222859. http://www.srpnet.com/about/pdfx/ngsintake.pdf. Retrieved 2011-09-19.

- ^ a b "US Energy Information Administration electric power plant data". US Department of Energy. http://205.254.135.24/cneaf/electricity/page/eia906_920.html. Retrieved 2011-05-04.

- ^ "EPA Clean Air Markets Data & Maps". US Environmental Protection Agency. http://camddataandmaps.epa.gov/gdm/index.cfm. Retrieved 2011-05-30.

- ^ "GE Water & Process Technologies – RCC Thermal Products & ZLD". General Electric. http://www.gewater.com/pdf/events/2009/power_ind/GE-Thermal-Products-ZLD.pdf. Retrieved 2011-05-20.

External links

Power stations in Arizona Coal-fired

generating stationsHydroelectric dams Wind farms Solar thermal plants Nuclear plants Utility companies Arizona Electric Power Cooperative • Arizona Public Service • Salt River Project • Tucson Electric PowerCategories:- Coal-fired power stations in Arizona

- Buildings and structures in Coconino County, Arizona

- Arizona geography stubs

- United States power station stubs

Wikimedia Foundation. 2010.