- Tea processing

-

Main article: Tea

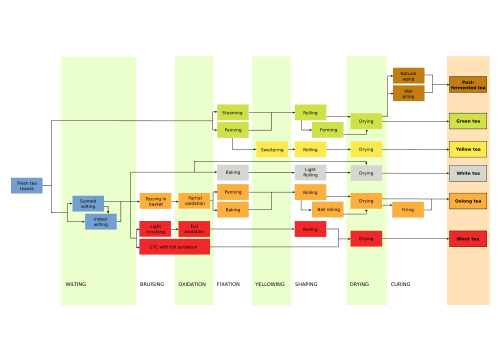

Tea processing is the method in which the leaves from the tea plant Camellia sinensis are transformed into the dried leaves for brewing tea. The categories of tea are distinguished by the processing they undergo. In its most general form, tea processing involves different manners and degree of oxidation of the leaves, stopping the oxidation, forming the tea and drying it. The innate flavour of the dried tea leaves is determined by the type of cultivar of the tea bush, the quality of the plucked tea leaves, and the manner and quality of the production processing they undergo.

Contents

General

Although each type of tea has different taste, smell, and visual appearance, tea processing for all tea types consists of a very similar set of methods with only minor variations:

Tea plucking done by women tea pickers at Puttabong Tea Estate, Darjeeling

Tea plucking done by women tea pickers at Puttabong Tea Estate, Darjeeling Worker picking tea flushes in Tanzania.

Worker picking tea flushes in Tanzania.

- Picking: Tea leaves and flushes, which includes a terminal bud and two young leaves, are plucked from Camellia sinensis bushes typically twice a year during early spring and early summer or late spring.[1][2] Autumn or winter pickings of tea flushes are much less common, though they occur when climate permits. Picking is done by hand when a higher quality tea is needed, or where labour costs are not prohibitive. Hand-picking is done by pulling the flush with a snap of the wrist and does not involve twisting or pinching the flush, since doing the latter reduces the quality of the leaves. Tea flushes and leaves can also be picked by machine, though there will be more broken leaves and partial flushes. It is also more difficult to harvest by machine on mountain slopes where tea is often grown.

- Withering/ Wilting: The tea leaves will begin to wilt soon after picking, with a gradual onset of enzymatic oxidation. Withering is used to remove excess water from the leaves and allows a very slight amount of oxidation.[1] The leaves can be either put under the sun or left in a cool breezy room to pull moisture out from the leaves.[2] The leaves sometimes lose more than a quarter of their weight in water during withering. The process is also important in promoting the breakdown of leaf proteins into free amino acid and increases the availability of freed caffeine both of which changes the taste of the tea.[3]

- Bruising: In order to promote and quicken oxidation, the leaves may be bruised by shaking and tossing in a bamboo tray,[1] tumbling in baskets or by being kneaded or rolled over by heavy wheels. The bruising breaks down the structures inside and outside of the leaf cells and allows from the co-mingling of oxidative enzymes with various substrates, which allows for the beginning of oxidation.[3] This also releases some of the leaf juices, which may aid in oxidation and change the taste profile of the tea.

- Oxidation / Fermentation: For teas that require oxidation, the leaves are left on their own in a climate-controlled room where they turn progressively darker. This is accompanied by agitation in some cases.[1] In this process the chlorophyll in the leaves is enzymatically broken down, and its tannins are released or transformed. This process is sometimes referred to as "fermentation" in the tea industry. The tea producer may choose when the oxidation should be stopped, which depends on the desired qualities in the final tea as well as the weather conditions (heat and humidity). For light oolong teas this may be anywhere from 5-40% oxidation, in darker oolong teas 60-70%, and in black teas 100% oxidation. Oxidation is highly important in the formation of many taste and aroma compounds, which give a tea its liquor colour, strength, and briskness.[3] Depending on the type of tea desired, under or over-oxidation/fermentation can result in grassy flavours, or overly thick winey flavours.[4]

- Fixation / Kill-green: Kill-green or shāqīng (殺青) is done to stop the tea leaf oxidation at a desired level. This process is accomplished by moderately heating tea leaves, thus deactivating their oxidative enzymes and removing unwanted scents in the leaves, without damaging the flavour of the tea.[1] Traditionally, the tea leaves are panned in a wok[1] or steamed,[2] but with advancements in technology, kill-green is sometimes done by baking or "panning" in a rolling drum. In some white teas and some black teas such as CTC blacks, kill-green is done simultaneously with drying.[4]

- Sweltering / Yellowing: Unique to yellow teas, warm and damp tea leaves from after kill-green are allowed to be lightly heated in a closed container, which causes the previously green leaves to yellow. The resulting leaves produce a beverage that has a distinctive yellowish-green hue due to transformations of the leaf chlorophyll.[5] Through being sweltered for 6–8 hours at close to human body temperatures, the amino acids and polyphenols in the processed tea leaves undergo chemical changes to give this tea its distinct briskness and mellow taste.[6]

- Rolling / Shaping:The damp tea leaves are then rolled to be formed into wrinkled strips, by hand[1] or using a rolling machine which causes the tea to wrap around itself. This rolling action also causes some of the sap, essential oils, and juices inside the leaves to ooze out, which further enhances the taste of the tea.[1] The strips of tea can then be formed into other shapes, such as being rolled into spirals, kneaded and rolled into pellets, or tied into balls, cones and other elaborate shapes. In many type of oolong, the rolled strips of tea leaf are then rolled to spheres or half spheres and is typically done by placing the damp leaves in large cloth bags, which are then kneaded by hand or machine in a specific manner.

- Drying: Drying is done to "finish" the tea for sale. This can be done in a myriad of ways including panning, sunning, air drying, or baking. However, baking is usually the most common. Great care must be taken to not over-cook the leaves. The drying of the produced tea are responsible for many new flavour compounds particularly important in green teas.[7]

- Aging / Curing: While not always required, some teas required additional aging, secondary-fermentation, or baking to reach their drinking potential. For instance, a green tea puerh, prior to curing into a post-fermented tea, is often bitter and harsh in taste, but becomes sweet and mellow through fermentation by age or dampness.[2] Additionally, oolong can benefit from aging if fired over charcoal.[1] Flavoured teas are manufactured in this stage by spraying the tea with aromas and flavours or by storing them with their flavorants.

Without careful moisture and temperature control during its manufacture and life thereafter, fungi will grow on tea. This form of fungus causes real fermentation that will contaminate the tea and may render the tea unfit for consumption.

Type specific processing

Tea is traditionally classified based on the degree or period of "fermentation" the leaves have undergone[8][9]:

-

Organic Darjeeling White Tea processed at Arya Tea Estate in Darjeeling

Organic Darjeeling White Tea processed at Arya Tea Estate in Darjeeling

- White tea

- Young leaves or new growth buds that have undergone minimal oxidation through a slight amount of withering before halting the oxidation with heat.[10][11] Withering of the leaves can last from around one to three days depending on the season and temperature of the processing environment.[11][12]. Though the young leaves may be shaped before drying, leaf buds processed into white tea are usually dried immediately after withering. The buds may be shielded from sunlight to prevent the formation of chlorophyll. White tea is produced in lesser quantities than most other styles, and can be correspondingly more expensive than tea from the same plant processed by other methods. It is less well known in countries outside of China, though this is changing with increased western interest in organic or premium teas.

- Green tea

- This tea has undergone the least amount of oxidation. The oxidation process is halted by the quick application of heat after tea picking, either with steam, the Japanese method, or by dry cooking in hot pans, the traditional Chinese method.[7] Tea leaves may be left to dry as separate leaves or they may be rolled into small pellets to make Gunpowder tea. This process is time consuming and is typically done with pekoes of higher quality. The tea is processed within one to two days of harvesting, and if done correctly retains most of the chemical composition of the fresh leaves from which it was produced.[7]

- Oolong tea

- This tea's oxidation is stopped somewhere between the standards for green tea and black tea. The processing typically takes two to three days from withering to drying[1] with a relatively short oxidation period[7] of several hours. In Chinese, semi-oxidized teas are collectively grouped as blue tea (青茶, literally: blue-green tea / "celadon tea"), while the term "oolong" is used specifically as a name for certain semi-oxidized teas.[13] Common wisdom about lightly oxidized teas in Taiwan (a large producer of Oolong) is that too little oxidation upsets the stomach of some consumers. Even so, some producers attempt to minimize oxidation in order to produce a specific taste.

- Black tea

- The tea leaves are allowed to completely oxidize. Black tea is the most common form of tea in southern Asia (Sri Lanka, India, Pakistan, Bangladesh, etc.) and in the last century many African countries including Kenya, Burundi, Rwanda, Malawi and Zimbabwe. The literal translation of the Chinese word is red tea, which is used by some tea lovers. The Chinese, Japanese, and Koreans call it red tea because the actual tea liquid is red. Speakers of many other languages call it black tea because the tea leaves used to brew it are usually black. However, red tea may also refer to rooibos, an increasingly popular South African tisane. Black tea is first withered to induce protein breakdown and reduce water content (68-77% of original), heavily rolled or torn to bruise and disrupt the leaf cell structures and activate oxidation.[3][7] The oxidation process takes between 45–90 minutes[7] to 3 hours[3] and is done at high humidity between 20-30 degrees Celsius, transforming much of the catechins of the leaves into complex tannin.[7] Black tea is further classified as either orthodox or as Crush, Tear, Curl (CTC), a production method developed around 1932. Unblended black teas are also identified by the estate they come from, their year and the flush (first, second or autumn). Orthodox processed black teas are further graded according to the post-production leaf quality by the Orange Pekoe system, while CTC teas use a different grading system.[14]

- Post-fermented tea

- Teas that are allow to undergo a second oxidation after the fixation of the tea leaves, such as Pu-erh, Liu'an, and Liubao, are collectively referred to as secondary or post-fermentation teas in English.[15] In Chinese they are categorized as Dark tea or black tea. This is not to be confused with the English term Black tea, known in Chinese as red tea. Pu-erh, also known as Póu léi (Polee) in Cantonese is the most common type of post-fermetation tea in the market.

- Yellow tea

- This tea is processed in a similar manner to green tea, but instead of immediate drying after fixation, it is stacked, covered, and gently heated in a humid environment. This initiates oxidation in the chlorophyll of the leaves through non-enzymatic and non-microbial means, which results in a yellowish or greenish-yellow colour.[5] This tea is popular in Japanese tea ceremonies due to its appearance, but the flavor as well is distinctive. The name derives from this "yellowing" process, and possibly includes a reference to the colour yellow which indicates the emperor, as this was a tea popular at court ceremonies for its bright colour and smooth pouring before the Imperial court.

-

Da Hong Pao tea, an Oolong tea

-

Fuding Bai Hao Yinzhen tea, a white tea

-

Green Pu-erh tuo cha, a type of compressed raw pu-erh

References

- ^ a b c d e f g h i j Li, Guang (2007), Ling Chun Chin, ed., "The Traditional Processing of Wuyi Rock Teas: An Interview with Master Ling Ping Xang", The Art of Tea (Wushing Book Publisher) (2): 76–83

- ^ a b c d Chan, Kam Pong (November 2006). First-Step to Chinese Puerh Tea (簡易中國普洱茶). Taipei, Taiwan: WuShing Books Publications Co. Ltd.. ISBN 978-957-8964-33-4.

- ^ a b c d e Roberts, E. A. H. (1958), "The Chemistry of Tea Manufacture", J. Sci. Food Agric. 9

- ^ a b "Detection of optimum fermentation time for black tea manufacturing using electronic nose". Sensors and Actuators B 122: 627–634. 2007.

- ^ a b ZHOU, Ji-rong; CHEN, Yu-qiong; SUN, Ya; NI, De-jiang (2005), "Studies on the Piling Technological Effects on Luyuan Yellow Tea", Food Science

- ^ GONG, Yong xin; CAI, Lie wei; CAI, Shi wen; JIN, Hua jun (2000), "Study on the Effect of Stack cover Process on the Taste of Yellow Tea", JOURNAL OF TEA SCIENCE

- ^ a b c d e f g Graham, Harold N. (1992), "Green Tea Composition, Consumption, and Polyphenol Chemistry", PREVENTIVE MEDICINE 21: 334–350

- ^ StarChefs (2006). "The Rainbow of Tea". http://www.starchefs.com/features/tea/html/types.shtml. Retrieved 2006-12-21.

- ^ (in Chinese) Tea processing: Introduction to the Six Tea Manufacturing Processes, 中国文艺版权, http://www.wenyi.com/culture/TEA/chaye/cyjg.htm

- ^ Zhang, Li Wang (1994-04), "A Further Study white tea quality control (再探白茶品质的控)制" (in Chinese), Chinese Tea Processing

- ^ a b Guo, Li; Kai, Liang Sui; Lin, Chi (2011), "Reasearch regarding the standardization of Chinese white tea wilting processes (中国白茶的标准化萎凋工艺研究)" (in Chinese), Chinese Agricultural Science Bulletin 27 (2): 382-385

- ^ Huang, Guo Zhi (1996), "The steps for processing Yinghong no.9 into White Tea (英红九号加工白茶的技术指标研究)"" (in Chinese), China Guangdong Tea 2

- ^ The Best Tea House Co. Ltd. (2005). "The Classification and Production of Tea" (in Chinese). http://www.besttea.com.hk/tea_categories.htm. Retrieved 2006-12-21.

- ^ Hoh, Erling; Mair, Victor H. (2009), The True History of Tea, Thames & Hudson, Thames & Hudson, ISBN 978-0500251461

- ^ Wen, Zhijie; Zhang, Ling Yun; Wu, Ping; He, Yong Qiang (2010), "Research on the action on microbes on post-fermented tea processing (黑茶加工中微生物作用的研究)" (in Chinese), Tea Communication 37 (2)

External links

- Tea processing steps with explanations (Chinese)

- Government site describing tea production (Chinese)

Tea Black tea Oolong tea - Bai Ji Guan

- Red Robe

- Darjeeling Oolong

- Dongding (Tung-ting)

- Dong Fang Mei Ren

- Huangjin Gui (Golden Osmanthus)

- Qilan tea

- Pouchong

- Rou Gui

- Shui Jin Gui

- Shui Hsien (Shui Xian)

- Tie Luohan

- Tieguanyin (Iron Goddess)

Green tea - Aracha

- Bancha

- Green Spiral

- Chun Mee

- Da Fang

- Genmaicha

- Liuan Leaf

- Gunpowder

- Gyokuro

- Hojicha

- Hou Kui

- Huang Shan Mao Feng

- Hyson

- Kabusecha

- Kamairicha

- Konacha

- Kukicha

- Longjing (Dragon Well)

- Matcha

- Mao Jian

- Mecha

- Meng Ding Gan Lu

- Sencha

- Shincha

- Tamaryokucha

White tea Yellow tea Post-fermented tea Blended and

flavoured teasTea culture Tea beverages Other - Camellia sinensis (tea plant)

- Tea bag

- Teapot

- Consumption

- Flowering tea

- Glass-holder

- Health effects

- Tea processing

- Samovar

- Tea brick

- Tea garden

- Tea house

- Tea tasting

- Teakettle

See also Categories:- Tea

- Tea varieties

Wikimedia Foundation. 2010.