- Mooney–Rivlin solid

-

Continuum mechanics  LawsScientists

LawsScientistsIn continuum mechanics, a Mooney–Rivlin solid[1][2] is a hyperelastic material model where the strain energy density function

is a linear combination of two invariants of the left Cauchy–Green deformation tensor

is a linear combination of two invariants of the left Cauchy–Green deformation tensor  . The model was proposed by Melvin Mooney in 1940 and expressed in terms of invariants by Ronald Rivlin in 1948.

. The model was proposed by Melvin Mooney in 1940 and expressed in terms of invariants by Ronald Rivlin in 1948.The strain energy density function for an incompressible Mooney–Rivlin material is[3][4]

where C1 and C2 are empirically determined material constants, and

and

and  are the first and the second invariant of the unimodular component of the left Cauchy–Green deformation tensor:[5]

are the first and the second invariant of the unimodular component of the left Cauchy–Green deformation tensor:[5]where

is the deformation gradient. For an incompressible material, J = 1.

is the deformation gradient. For an incompressible material, J = 1.Contents

Derivation

The Mooney–Rivlin model is a special case of the generalized Rivlin model (also called polynomial hyperelastic model[6]) which has the form

with C00 = 0 where Cpq are material constants related to the distortional response and Dm are material constants related to the volumetric response. For a compressible Mooney–Rivlin material N = 1,C01 = C2,C11 = 0,C10 = C1,M = 1 and we have

If C01 = 0 we obtain a neo-Hookean solid, a special case of a Mooney–Rivlin solid.

For consistency with linear elasticity in the limit of small strains, it is necessary that

where κ is the bulk modulus and μ is the shear modulus.

Cauchy stress in terms of strain invariants and deformation tensors

The Cauchy stress in a compressible hyperelastic material with a stress free reference configuration is given by

For a compressible Mooney–Rivlin material,

Therefore, the Cauchy stress in a compressible Mooney–Rivlin material is given by

The quantity

has the form of a pressure. The stress can then be expressed in the form

For an incompressible Mooney–Rivlin material with J = 1

Note that if J = 1 then

Then, from the Cayley-Hamilton theorem,

Hence, the Cauchy stress can be expressed as

where

Cauchy stress in terms of principal stretches

In terms of the principal stretches, the Cauchy stress differences for an incompressible hyperelastic material are given by

For an incompressible Mooney-Rivlin material,

Therefore,

Since λ1λ2λ3 = 1. we can write

Then the expressions for the Cauchy stress differences become

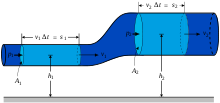

Uniaxial extension

For the case of an incompressible Mooney–Rivlin material under uniaxial elongation,

and

and  . Then the true stress (Cauchy stress) differences can be calculated as:

. Then the true stress (Cauchy stress) differences can be calculated as:Simple tension

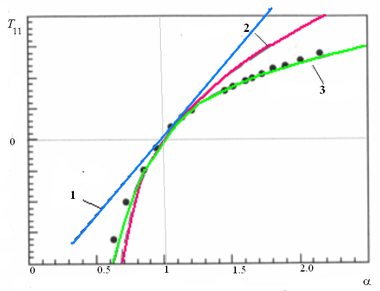

Comparison of experimental results (dots) and predictions for Hooke's law(1, blue line), neo-Hookean solid(2, red line) and Mooney–Rivlin solid models(3, green line)

In the case of simple tension, σ22 = σ33 = 0. Then we can write

In alternative notation, where the Cauchy stress is written as

and the stretch as α, we can write

and the stretch as α, we can writeand the engineering stress (force per unit reference area) for an incompressible Mooney–Rivlin material under simple tension can be calculated using

. Hence

. HenceIf we define

then

The slope of the

versus β line gives the value of C2 while the intercept with the

versus β line gives the value of C2 while the intercept with the  axis gives the value of C1. The Mooney–Rivlin solid model usually fits experimental data better than Neo-Hookean solid does, but requires an additional empirical constant.

axis gives the value of C1. The Mooney–Rivlin solid model usually fits experimental data better than Neo-Hookean solid does, but requires an additional empirical constant.Equibiaxial tension

In the case of equibiaxial tension, the principal stretches are λ1 = λ2 = λ. If, in addition, the material is incompressible then λ3 = 1 / λ2. The Cauchy stress differences may therefore be expressed as

The equations for equibiaxial tension are equivalent to those governing uniaxial compression.

Pure shear

A pure shear deformation can be achieved by applying stretches of the form [7]

The Cauchy stress differences for pure shear may therefore be expressed as

Therefore

For a pure shear deformation

Therefore I1 = I2.

Simple shear

The deformation gradient for a simple shear deformation has the form[7]

where

are reference orthonormal basis vectors in the plane of deformation and the shear deformation is given by

are reference orthonormal basis vectors in the plane of deformation and the shear deformation is given byIn matrix form, the deformation gradient and the left Cauchy-Green deformation tensor may then be expressed as

Therefore,

The Cauchy stress is given by

For consistency with linear elasticity, clearly μ = 2(C1 + C2) where μ is the shear modulus.

Rubber

Elastic response of rubber-like materials are often modeled based on the Mooney—Rivlin model. The constants C1,C2 are determined by the fitting predicted stress from the above equations to experimental data. The recommended tests are uniaxial tension, equibiaxial compression, equibiaxial tension, uniaxial compression, and for shear, planar tension and planar compression. The two parameter Mooney–Rivlin model is usually valid for strains less than 100%.

Notes and references

- ^ Mooney, M., 1940, A theory of large elastic deformation, Journal of Applied Physics, 11(9), pp. 582-592.

- ^ Rivlin, R. S., 1948, Large elastic deformations of isotropic materials. IV. Further developments of the general theory, Philosophical Transactions of the Royal Society of London. Series A, Mathematical and Physical Sciences, 241(835), pp. 379-397.

- ^ Boulanger, P. and Hayes, M. A., 2001, Finite amplitude waves in Mooney–Rivlin and Hadamard materials, in Topics in Finite Elasticity, ed. M. A Hayes and G. Soccomandi, International Center for Mechanical Sciences.

- ^ C. W. Macosko, 1994, Rheology: principles, measurement and applications, VCH Publishers, ISBN 1-56081-579-5.

- ^ The characteristic polynomial of the linear operator corresponding to the second rank three-dimensional Finger tensor (also called the left Cauchy–Green deformation tensor) is usually written

- ^ Bower, Allan (2009). Applied Mechanics of Solids. CRC Press. ISBN 1439802472. http://solidmechanics.org/. Retrieved January 2010.

- ^ a b Ogden, R. W., 1984, Nonlinear elastic deformations, Dover

See also

Categories:- Continuum mechanics

- Non-Newtonian fluids

- Rubber properties

- Solid mechanics

Wikimedia Foundation. 2010.

![\boldsymbol{\sigma} = \cfrac{2}{J}\left[\cfrac{1}{J^{2/3}}\left(\cfrac{\partial{W}}{\partial \bar{I}_1} + \bar{I}_1~\cfrac{\partial{W}}{\partial \bar{I}_2}\right)\boldsymbol{B} -

\cfrac{1}{J^{4/3}}~\cfrac{\partial{W}}{\partial \bar{I}_2}~\boldsymbol{B} \cdot\boldsymbol{B} \right] + \left[\cfrac{\partial{W}}{\partial J} -

\cfrac{2}{3J}\left(\bar{I}_1~\cfrac{\partial{W}}{\partial \bar{I}_1} + 2~\bar{I}_2~\cfrac{\partial{W}}{\partial \bar{I}_2}\right)\right]~\boldsymbol{\mathit{1}}](b/74b172f8e241a41aa805133430a6105a.png)

![\boldsymbol{\sigma} = \cfrac{2}{J}\left[\cfrac{1}{J^{2/3}}\left(C_1 + \bar{I}_1~C_2\right)\boldsymbol{B} -

\cfrac{1}{J^{4/3}}~C_2~\boldsymbol{B} \cdot\boldsymbol{B} \right] + \left[2D_1(J-1)-

\cfrac{2}{3J}\left(C_1\bar{I}_1 + 2C_2\bar{I}_2~\right)\right]\boldsymbol{\mathit{1}}](4/d04c0aa5c4eee115f9a533cec1046d6c.png)

![\boldsymbol{\sigma} = \cfrac{1}{J}\left[-p~\boldsymbol{\mathit{1}} + \cfrac{2}{J^{2/3}}\left(C_1 + \bar{I}_1~C_2\right)\boldsymbol{B} -

\cfrac{2}{J^{4/3}}~C_2~\boldsymbol{B}\cdot\boldsymbol{B} \right]](3/9a37e3888cc72c30bd4381a0b649119b.png)