- Shear modulus

-

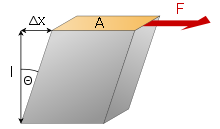

Shear modulus SI symbol: G SI unit: gigapascal Derivations from other quantities: G = τ / γ In materials science, shear modulus or modulus of rigidity, denoted by G, or sometimes S or μ, is defined as the ratio of shear stress to the shear strain:[1]

where

= shear stress;

= shear stress;- F is the force which acts

- A is the area on which the force acts

- in engineering,

= shear strain. Elsewhere, γxy = θ

= shear strain. Elsewhere, γxy = θ - Δx is the transverse displacement

- l is the initial length

Shear modulus is usually expressed in gigapascals (GPa) or in thousands of pounds per square inch (kpsi).

The shear modulus is always positive.

Contents

Explanation

Material Typical values for

shear modulus (GPa)

(at room temperature)Diamond[2] 478. Steel[3] 79.3 Copper[4] 44.7 Titanium[3] 41.4 Glass[3] 26.2 Aluminium[3] 25.5 Polyethylene[3] 0.117 Rubber[5] 0.0006 The shear modulus is one of several quantities for measuring the stiffness of materials. All of them arise in the generalized Hooke's law:

- Young's modulus describes the material's response to linear strain (like pulling on the ends of a wire),

- the bulk modulus describes the material's response to uniform pressure, and

- the shear modulus describes the material's response to shearing strains.

The shear modulus is concerned with the deformation of a solid when it experiences a force parallel to one of its surfaces while its opposite face experiences an opposing force (such as friction). In the case of an object that's shaped like a rectangular prism, it will deform into a parallelepiped. Anisotropic materials such as wood and paper exhibit differing material response to stress or strain when tested in different directions. In this case, when the deformation is small enough so that the deformation is linear, the elastic moduli, including the shear modulus, will then be a tensor, rather than a single scalar value.

Waves

Influences of selected glass component additions on the shear modulus of a specific base glass.[6]

In homogeneous and isotropic solids, there are two kinds of waves, pressure waves and shear waves. The velocity of a shear wave, (vs) is controlled by the shear modulus,

where

- G is the shear modulus

- ρ is the solid's density.

Shear modulus of metals

The shear modulus of metals measures the resistance to glide over atomic planes in crystals of the metal. In polycrystalline metals there are also grain boundary factors that have to be considered. In metal alloys, the shear modulus is observed to be higher than in pure metals due to the presence of additional sources of resistance to glide.

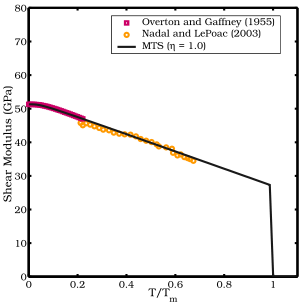

The shear modulus of metals is usually observed to decrease with increasing temperature. At high pressures, the shear modulus also appears to increase with the applied pressure. Correlations between the melting temperature, vacancy formation energy, and the shear modulus have been observed in many metals.[9]

Several models exist that attempt to predict the shear modulus of metals (and possibly that of alloys). Shear modulus models that have been used in plastic flow computations include:

- the MTS shear modulus model developed by[10] and used in conjunction with the Mechanical Threshold Stress (MTS) plastic flow stress model.[11][12]

- the Steinberg-Cochran-Guinan (SCG) shear modulus model developed by[13] and used in conjunction with the Steinberg-Cochran-Guinan-Lund (SCGL) flow stress model.

- the Nadal and LePoac (NP) shear modulus model[8] that uses Lindemann theory to determine the temperature dependence and the SCG model for pressure dependence of the shear modulus.

MTS shear modulus model

The MTS shear modulus model has the form:

where µ0 is the shear modulus at 0 K, and D and T0 are material constants.

SCG shear modulus model

The Steinberg-Cochran-Guinan (SCG) shear modulus model is pressure dependent and has the form

where, µ0 is the shear modulus at the reference state (T = 300 K, p = 0, η = 1), p is the pressure, and T is the temperature.

NP shear modulus model

The Nadal-Le Poac (NP) shear modulus model is a modified version of the SCG model. The empirical temperature dependence of the shear modulus in the SCG model is replaced with an equation based on Lindemann melting theory. The NP shear modulus model has the form:

where

and µ0 is the shear modulus at 0 K and ambient pressure, ζ is a material parameter, kb is the Boltzmann constant, m is the atomic mass, and f is the Lindemann constant.

See also

References

- ^ IUPAC, Compendium of Chemical Terminology, 2nd ed. (the "Gold Book") (1997). Online corrected version: (2006–) "shear modulus, G".

- ^ McSkimin, H.J.; Andreatch, P. (1972). "Elastic Moduli of Diamond as a Function of Pressure and Temperature". J. Appl. Phys. 43 (7): 2944–2948. Bibcode 1972JAP....43.2944M. doi:10.1063/1.1661636.

- ^ a b c d e Crandall, Dahl, Lardner (1959). An Introduction to the Mechanics of Solids. Boston: McGraw-Hill. ISBN 0070134413.

- ^ Material properties

- ^ Spanos, Pete (2003). "Cure system effect on low temperature dynamic shear modulus of natural rubber". Rubber World. http://www.thefreelibrary.com/Cure+system+effect+on+low+temperature+dynamic+shear+modulus+of...-a0111451108.

- ^ Shear modulus calculation of glasses

- ^ Overton, W.; Gaffney, John (1955). "Temperature Variation of the Elastic Constants of Cubic Elements. I. Copper". Physical Review 98 (4): 969. Bibcode 1955PhRv...98..969O. doi:10.1103/PhysRev.98.969.

- ^ a b Nadal, Marie-Hélène; Le Poac, Philippe (2003). "Continuous model for the shear modulus as a function of pressure and temperature up to the melting point: Analysis and ultrasonic validation". Journal of Applied Physics 93 (5): 2472. Bibcode 2003JAP....93.2472N. doi:10.1063/1.1539913.

- ^ March, N. H., (1996), Electron Correlation in Molecules and Condensed Phases, Springer, ISBN 0306448440 p. 363

- ^ Varshni, Y. (1970). "Temperature Dependence of the Elastic Constants". Physical Review B 2 (10): 3952. Bibcode 1970PhRvB...2.3952V. doi:10.1103/PhysRevB.2.3952.

- ^ Chen, Shuh Rong; Gray, George T. (1996). "Constitutive behavior of tantalum and tantalum-tungsten alloys". Metallurgical and Materials Transactions A 27 (10): 2994. Bibcode 1996MMTA...27.2994C. doi:10.1007/BF02663849.

- ^ Goto, D. M.; Garrett, R. K.; Bingert, J. F.; Chen, S. R.; Gray, G. T. (2000). "The mechanical threshold stress constitutive-strength model description of HY-100 steel". Metallurgical and Materials Transactions A 31 (8): 1985–1996. doi:10.1007/s11661-000-0226-8.

- ^ Guinan, M; Steinberg, D (1974). "Pressure and temperature derivatives of the isotropic polycrystalline shear modulus for 65 elements". Journal of Physics and Chemistry of Solids 35 (11): 1501. Bibcode 1974JPCS...35.1501G. doi:10.1016/S0022-3697(74)80278-7.

Elastic moduli for homogeneous isotropic materials Bulk modulus (K) · Young's modulus (E) · Lamé's first parameter (λ) · Shear modulus (G) · Poisson's ratio (ν) · P-wave modulus (M)Conversion formulas Homogeneous isotropic linear elastic materials have their elastic properties uniquely determined by any two moduli among these, thus given any two, any other of the elastic moduli can be calculated according to these formulas.

Categories:

Categories:

Wikimedia Foundation. 2010.

![\mu(p,T) = \frac{1}{\mathcal{J}(\hat{T})}

\left[

\left(\mu_0 + \frac{\partial \mu}{\partial p} \cfrac{p}{\eta^{1/3}} \right)

(1 - \hat{T}) + \frac{\rho}{Cm}~k_b~T\right]; \quad

C := \cfrac{(6\pi^2)^{2/3}}{3} f^2](1/7616e4c9faafde0355f4179475cde39b.png)

![\mathcal{J}(\hat{T}) := 1 + \exp\left[-\cfrac{1+1/\zeta}

{1+\zeta/(1-\hat{T})}\right] \quad

\text{for} \quad \hat{T}:=\frac{T}{T_m}\in[0,1+\zeta],](0/a70586526461814feccb6bac91d254f0.png)