- Cromford Mill

-

Coordinates: 53°06′32″N 1°33′22″W / 53.1090°N -1.5560°E

Cromford Mill

Cromford MillCotton Spinning Mill (Water frame) Structural system Stone Arkwright Coordinates 53°06′32″N 1°33′22″W / 53.1090°N -1.5560°E Construction Built 1772 Employees 200 Floor count 5 Design team Awards and prizes and listings Grade 1 listed Cromford Mill was the first water-powered cotton spinning mill developed by Richard Arkwright in 1771 in Cromford, Derbyshire, England, which laid the foundation of his fortune and was quickly copied by mills in Lancashire, Germany and the United States. It forms the centre piece of the Derwent Valley Mills, now a World Heritage Site.

Contents

History

Following the invention of the flying shuttle for weaving cotton in 1733 the demand for spun cotton increased enormously in England. Machines for carding and spinning had already been developed but were inefficient and the cotton produced was of insufficient quality to form the warp of a fabric. In 1769, Arkwright patented a water frame to use the extra power of a water mill after he had set up a horse powered mill in Nottingham.

He chose the site at Cromford because it had year-round supply of warm water from the Cromford Sough which drained water from nearby Wirksworth lead mines, together with Bonsall Brook. Here he built a five storey mill, with the backing of Jedediah Strutt, Samuel Need and John Smalley. Starting from 1772, he ran the mills day and night with two 12 h shifts.

He started with 200 workers, more than the locality could provide, so he built housing for them nearby, one of the first manufacturers to do so. Most of the employees were women and children, the youngest being only 7 years old. Later, the minimum age was raised to 10 and the children were given 6 h of education a week, so that they could do the record keeping that their illiterate parents could not.

Water frame

Initially the first stage of the process was hand carding, but in 1775 he took out a second patent for a water-powered carding machine and this led to increased output and the fame of his factory rapidly spread. He was soon building further mills on this site and others and eventually employed 1,000 workers at Cromford. Many other mills were built under licence, including mills in Lancashire, Scotland and Germany. Samuel Slater, an apprentice of Jedediah Strutt, took the secrets of Arkwright's machines to Lowell, Massachusetts, America, where he founded a cotton industry. But Arkwright's success led to his patents being challenged in court and his second patent was overturned as having no originality. But by the time of his death in 1792, he was the wealthiest untitled person in Britain.[1]

The opening of the Cromford Canal 1793 linked Arkwright's Mill to the major Midland and Northern cities, although use of the canal was to decline as traffic moved onto the railways.[2]

The gate to Cromford Mill was shut at precisely 6 a.m. and 6 p.m. every day, and any worker who failed to get through it not only lost a day's pay but also was fined another day's pay. In 1779, Arkwright installed a cannon, loaded with grapeshot, just inside the factory gate [3], as a warning to would-be rioting textile workers, who had burned down another of his mills in Birkacre, Lancashire. The cannon was never used.

The cotton mill finally ceased operation in the nineteenth century and the buildings were used for other purposes, finally a dyeing plant. In 1979, the Grade I listed site was bought by the Arkwright Society who commenced the long task of restoring it to its original state.

The importance of this site is not that it was the first but that it was the first successful cotton spinning factory. It showed unequivocally the way ahead and was widely emulated.

Today, the mill is open to the public every day, and it attracts visitors from all over the world. Facilities include a visitors' centre, shops and a cafe. It is planned to stage a major exhibition with working machinery, with the addition of meeting rooms for educational groups, together with a library and a study centre.[4]

The nearby Cromford Canal towpath to High Peak Junction, and onwards towards Ambergate, is listed as a Biological Site of Special Scientific Interest (SSSI).[5]

Illustrations

The mill restoration in progress 2009

The state of the mill in 1995

-

The only remaining usable mill building in 1995, parts of it being presentable enough for guided tours. At the time work was in progress to replace many of the stone lintols and to replace the original Georgian windows. The single storey building was originally the full height but had been lost in the 1890 fire

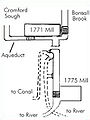

The mill waterworks

-

A composite diagram of the watercourses. Originally the sough drained into the brook back in the village, and both powered the original mill. The sough was separated and brought along a channel on the south side of Mill Road to the aqueduct. Both then supplied the second mill. A complicated set of channels and sluices controlled the supply to the mill, or, on Sundays, the canal, with the surprus drained into the river.

See also

References

External links

- Arkwright Society - Cromford Mill - with tour information

- Cromford village website

Categories:- 1772 architecture

- Textile mills in Derbyshire

- Industrial Revolution

- Spinning

- Grade I listed buildings in Derbyshire

- Watermills in England

- Museums in Derbyshire

- Textile museums in the United Kingdom

- Industry museums in the United Kingdom

- Textile mills built in the 18th century

- Visitor attractions in Derbyshire

Wikimedia Foundation. 2010.