- Cue stick

-

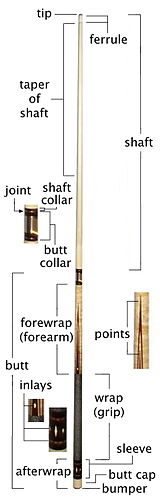

A cue stick (or simply cue, more specifically pool cue, snooker cue, or billiards cue), is an item of sporting equipment essential to the games of pool, snooker and carom billiards. It is used to strike a ball, usually the cue ball. Cues are tapered sticks, typically about 58 inches (1.5 m) long and 18–21 ounces (510–600 g) for pool (shorter for carom and longer for snooker, and lighter for both). Most cues are made of wood, but occasionally the wood is covered or bonded with other materials including, graphite, carbon fiber or fiberglass. An obsolete term for a cue, used from the 16th to early 19th centuries, is billiard stick.[3][4]

Contents

History

The forerunner of the cue was the mace, an implement similar to a light-weight golf club, with a foot that was generally used to shove rather than strike the cue ball.[3] When the ball was frozen against a rail cushion, use of the mace was difficult (the foot would not fit under the edge of the cushion to strike the ball squarely), and by 1670 experienced players often used the tail or butt end of the mace instead.[3] The term "cue" comes from queue, the French word for "tail", in reference to this practice,[3] a style of shooting that eventually led to the development of separate, footless cue sticks by about 1800, used initially as adjuncts to the mace,[3] which remained in use until well into the 19th century.[5] In public billiard rooms only skilled players were initially allowed to use the cue, because the fragile cloth could be torn by novices.[3] The introduction of the cue, and the new game possibilities it engendered, led to the development of cushions with more rebound, initially stuffed with linen or cotton flocking, but eventually replaced by rubber.[3]

The idea of the cue initially was to try to strike the cue-ball as centrally as possible to avoid a miscue.[3] The concept of spin on the cue ball was discovered before cue-tips had been invented; e.g. striking the bottom of the cue ball to make it go backwards upon contact with an object ball.[3] François Mingaud was studying the game of billiards while being held in Paris as a political prisoner, and experimented with a leather cue tip. In 1807, he was released and demonstrated his invention.[3] Mingaud is also credited with the discovery that by raising the cue vertically, to the position adopted by the mace, he could perform what is now known as a massé shot.[3]

In pre-tip days, it was common for players to twist the ends of their cue into a plaster wall or ceiling so that a chalk-like deposit would form on the end, reducing the chance of a miscue.[3] The first systematic marketing of chalk was by John Carr[disambiguation needed

], a marker in John Bartley's billiard rooms in Bath. Between Carr and Bartley, it was discovered how "side" (sidespin) could be used to the advantage of players, and Carr began selling chalk in small boxes. He called it "twisting powder", and the magical impression this gave the public enabled him to sell it for a higher price than if they realized it was simply chalk in a small box.[3] "English", an American term for sidespin, derives from the British discovery of sidespin's effects, as "massé" comes from the French word for "mace".[3]

], a marker in John Bartley's billiard rooms in Bath. Between Carr and Bartley, it was discovered how "side" (sidespin) could be used to the advantage of players, and Carr began selling chalk in small boxes. He called it "twisting powder", and the magical impression this gave the public enabled him to sell it for a higher price than if they realized it was simply chalk in a small box.[3] "English", an American term for sidespin, derives from the British discovery of sidespin's effects, as "massé" comes from the French word for "mace".[3]Types

Pool and snooker cues average around 57 inches in length (148 cms) and are of three major types. The simplest type is a one-piece cue; these are generally stocked in pool halls for communal use. They have a uniform taper, meaning they decrease in diameter evenly from the end or butt to the tip. A second type is the two-piece cue, divided in the middle for ease of transport, usually in a cue case. A third variety is another two-piece cue, but with a joint located three-quarters down the cue (usually 12 or 16 inches away from the butt), known as a "three-quarter two-piece", used primarily by snooker players.

Pool

A typical two-piece cue for pocket billiards is usually made mostly of hard rock maple, with a fiberglass or phenolic resin ferrule, usually 0.75 to 1 inch (19 to 25 mm) long, and steel joint collars and pin. Pool cues average around 58 inches (150 cm) long, are commonly available in 17–21 ounces (0.48–0.60 kg) weights, with 19 ounces (0.54 kg) being the most common, and usually have a tip diameter in the range of 12.75 – 13.25 mm.[6] A conical taper, with the shaft gradually shrinking in diameter from joint to ferrule, is favored by some, but the "pro" taper is increasingly popular, straight for most of the length of the shaft from ferrule back, flaring to joint diameter only in the last 1⁄4 to 1⁄3 of the shaft. While there are many custom cuemakers, a very large number of quality pool cues are manufactured in bulk. In recent years, more technological materials such as fiberglass, carbon fiber, aluminum, etc., have been increasingly used for shafts and butts, and there has been a trend toward experimentation with rubber, memory foam and other soft wraps.

Carom

Carom billiards cues tend to be shorter and lighter than pool cues, with a shorter ferrule, a thicker butt and joint, a wooden joint pin (ideally) and collarless wood-to-wood joint, a conical taper, and a smaller tip diameter. Typical dimensions are 54–56 inches (140–140 cm) long, 16.5–18.5 ounces (0.47–0.52 kg) in weight, with a 11–12 mm diameter tip.[6] The specialization makes the cue stiffer, for handling the heavier billiard balls and acting to reduce deflection.[1]:79, 241 The wood used in carom cues can vary widely, and most quality carom cues are hand made.

Snooker

Cues designed for snooker will usually be slightly shorter than those for pool, at 57 inches (1.4 m), but with a detachable butt extension that can make the cue 6 inches (15 cm) or more longer.[7] Many snooker cues are jointed, usually with brass fittings, 2⁄3 or even 3⁄4 of the way back toward the butt bumper, providing an unusually long shaft, rather than at the half-way point, where pool and carom cues are jointed. This necessitates an extra-long cue case. Some models are jointed in two places, with the long shaft having a smooth and hard-to-notice wood-to-wood joint. Snooker cue tips are usually 8.5 – 10.5 mm in diameter, to provide more accuracy and finesse with snooker balls, smaller than pool and carom varieties. Snooker butts are usually flat on one side, so that the cue may be laid flat on the table bed and slid along the baize under a cushion to strike the cushion-ward side of the cue ball when it is frozen to the cushion (such a shot is not legal in pool or carom games under most rulesets). The very tactile flat part of the butt also helps the player develop a very specific way of holding the cue, consistent on every shot, so that the stroke is more uniform, shot after shot (snooker, in the case of many if not most shots, requires quite a bit more precision than pool).

Specialty

Manufacturers also provide a variety of specialty cues tailored to specific shots. Pool break cues have often thin tips made from very hard leather or phenolic resin to ensure that the full force of the stroke is transferred to the cue ball during the break shot, and to avoid excessive wear-and-tear on the tips and ferrules of players' main shooting cues. Phenolic-tipped break cues often have a merged phenolic ferrule-tip, instead of two separate pieces.

Jump cues are shorter, lighter (12 ounces and less) cues that make performing a legal jump shot easier, and also often have a very hard tip. Some standard-sized break cues include a two-piece butt allowing a player to remove the lower, heavier half of the butt to produce a jump cue; these are usually referred to as jump–break or break–jump cues. The uncommon massé cue is short and heavy, with a wider tip to aid in making massé shots.

Practitioners of artistic billiards and artistic pool sometimes have twenty or more cues, each specifically tailored to a particular trick shot. Other specialty cues have multiple sections, between which weights can be added. Another specialization is the butt extension, which can be slipped over or screwed into the normal butt, to lengthen the cue and reduce dependency on the mechanical bridge.

A high quality two-piece cue with a nearly invisible wood-to-wood joint, so that it looks like a cheap one-piece house cue, is called a sneaky pete.[8] Such a cue may be used by a hustler to temporarily fool unsuspecting gamblers into thinking that he or she is a novice.

Shaft

Shafts are made with various tapers, the two most common being the pro taper and the European taper. The pro taper has the same diameter from the tip to 30-35 cm (12-14 inches) toward the joint, at which point it begins to widen. The European taper widens continually and smoothly from the ferrule toward the joint. Despite their names, the continually sloping European taper is found in most North American bar and house cues, and not all professional players prefer a straight pro taper on their custom, two-piece models.

Tip

Dime- and nickel-radius cue tips (left to right, respectively)

Dime- and nickel-radius cue tips (left to right, respectively)

Leather tips of varying curvature and degrees of hardness are glued to (or in some cases screwed into) the ferrule. The de facto standard curvatures for a pool tip are dime- and nickel-radius, determined by shaping a tip so that when one puts a nickel or dime to it, they have the same curvature. The tip end of the cue will vary in diameter but is typically in the 9 to 14 millimeter range with 12–13 mm for pool cues, and 9–10 mm for Snooker cues being most common.

Rounder (i.e., smaller radius) tips impart spin to the cue ball more easily since the point of contact between the tip and the ball requires less distance from the center hit to impart the same amount of spin, due to the increased tangential contact. Tips for break and jump cues are usually nickel radius or even flatter, and sometimes made of harder materials such as phenolic resin; the shots are forceful, and usually require less spin.

A leather tip naturally compresses and hardens with subsequent shots. Without proper care, the surface of the tip can develop an undesired smoothness or glossiness which can significantly reduce the desired friction between the tip and the cue ball. Cue chalk is applied to the tip of the cue, ideally after every other shot or so, to help achieve the desired friction and minimize the chance of a miscue. This is especially important when the cue tip does not hit the cue ball in its center and thereby imparts spin to the cue ball.

There are different grades of hardness for tips, ranging from very soft to very hard. Softer tips (major brands include Elk Master) hold chalk better, but tend to degrade faster from abrasion (from chalk and scuffers), shaping (from cue tip shapers/tackers/picks), and mushrooming (the sides of the tip bulge out from long normal use or from hard hits that compact the tip in all directions). Harder tips (major brands include Blue Diamond Plus, Triangle and Le Professional or "Le Pro") maintain their shape much better, but because of their hardness, chalk tends to not hold as well as it does on softer tips. The hardness of a leather tip is determined from its compression and tanning during the manufacturing process.

All cue tips once were of a one-piece construction, as are many today (including LePro and Triangle). More recently some tips are made of layers that are laminated together (major brands include Moori and Talisman). Harder tips and laminated tips hold their shape better than softer tips and one-piece tips. Laminated tips generally cost more than one-piece tips due to their more extensive manufacturing process. A potential problem with layered tips is delamination, where a layer begins to separate from another or the tip completely comes apart. This is not common and usually results from improper installation, misuse of tip tools, or high impact massé shots. One-piece tips are not subject to this problem, but they do tend to mushroom more easily.

Ferrule

The end of the shaft has a cuff known as the ferrule which is used to hold the cue tip in place and to bear the brunt of impact with the cue ball so that the less resilient shaft wood does not split. Ferrules are predominantly made of ivory (in case of billiards and pool), carbon fiber, or a plastic such as melamine resin, aegis or phenolic resin which are extremely durable, high-impact materials that are resistant to cracking, chipping, and breaking. Brass is mostly used for snooker cues, although you might come across a Canadian snooker cue with a non-metal ferrule.

Joint

The heavy, lower piece of the cue is the cue butt, and the smaller, narrower end is the shaft. The two cue pieces are attached at the joint; normally a screw rising from butt end's joint (male) is threaded into a receptacle on the shaft (female), or vice versa. The joints are made of various materials, most frequently a plastic, brass, stainless steel, or wood outer layer, but some custom cues are made of bone, antlers, or other more expensive materials that are less common, but serve the same effect. Most snooker cues have brass-to-brass joints. The internal male and female connection points are almost always brass or steel because they respond less to temperature changes and thus expand and contract less than other materials, preserving the life of the cue. Joints have different sizes as well as different male and female ends on the shaft and butts of the cues. Traditional designs employ a fully threaded connection, while newer versions (marketed under such names as Uni-loc, Accu-loc and Tru-loc) employ half-threaded "quick pin release" connections that allow players to assemble and disassemble their cues faster.

Butt

The bulk of the weight of the cue is usually distributed in the cue butt portion. Whether the weight be 16 oz. or 22 oz., the weight change is mainly in the butt (usually in the core, under the wrap). A good cue will have this weight from the hardwood used, not added weight. Butts have varying constructions, from 3-piece to one-piece, as well as other custom versions that people have developed. These translate into different "feels" because of the distribution of weight as well as the balance point of the cue. Traditionally, players want the balance point of a cue near the top end of the wrap or around 7 inches from where they grip the butt. The cue butt is often inlaid with exotic woods such as cocobolo and bocote as well as other materials such as ebony and ivory. Usually parts of the butt are sectioned off with decorative rings. The use of various types of wraps on the cue butt, such as Irish linen or leather, provide a player with a better grip as well as absorbing moisture. Low-priced cues usually feature a nylon wrap which is considered not as good a "feel" as Irish Linen. Fiberglass and Graphite cues usually have a "Veltex" grip that is made of fiberglass/graphite, but is smoother and not glossy. Some people also prefer a cue with no wrap, and thus just a glossed finish on wood. Sometimes these no-wrap cues are more decorated because of the increased area for design and imagination. The butts of less expensive cues are usually spliced hardwood and a plastic covering while more high-end cues use solid rosewood or ebony.

Bumper

The final part a cue is the bumper, made of rubber (pool) or leather (snooker). Though often considered less important than other parts of a cue, this part is essential for protecting a cue. The bumper protects the cue when it rests on the ground or accidentally hits a wall, table, etc. Without the bumper, such impacts might crack the butt over an extended period of time. The "feel" of the cue (see below) is also an issue – without the bumper, the resonance of the cue hitting the cue ball may vibrate differently than in a cue with a properly attached, tight bumper. Though minuscule, the bumper also adds some weight on the end of the cue, preserving a balance that also impacts the feel of a cue.

Materials and design

The choice of materials used in the construction of the cue butt and the artistry of the design can lead to cues of great beauty and high price. Good quality pool cues are customarily made from straight grained hard rock maple wood, especially the shaft. Snooker cues, by contrast, are almost always made of ash wood, although you might come across one with a maple shaft. Maple is stiffer than ash, and cheaper. Cues are not always for play, some are purely collectible and can reach prices of tens of thousands of dollars for the materials they are made of and their exquisite craftsmanship. There have been a number of famous cue makers over the years. Among the most famous are George Balabushka, Herman Rambow, John Parris (Church Vale, London), Hunt & O'Byrne (Butler's Wharf, London), Palmer, Longoni, Samsara, Southwest, and Szamboti whose cues are often very valuable to collectors. A good B-brand for a snooker cue might be an Adam (made in Hong Kong) or an SM, which stands for snooker master.[citation needed] These "collector" cues often have ornate inlays with precious metals and stones, and varying woods to display designs and works of art, but mainly fine workmanship and top quality materials.[9] The woods can be stained to be absorbed into the wood and transparent or painted upon. These cues are also valued because of how well they perform. Competitors of custom cue makers and mass-production manufacturers usually try to make cues look like they are made of expensive materials by using overlays and decals. Although these deter the cost of the cues, they do not degrade the cue's effectiveness in gameplay. Another mark of quality is the precision that inlays are set in the wood. High quality inlays are set perfectly in the wood without any extra space to be filled; they are also perfectly symmetrical on all sides as well as clean cut so that the points are sharp and not rounded. The use of machines has aided much in the production of high quality inlays as well as other ornaments.

"Feel"

Different materials used in the construction of a cue can have an effect upon its playing "feel". Different hardnesses in tips, ferrules, woods, steels, and plastics alter the vibration felt in an experienced player's hands. The common view is that harder materials transfer less resonance through the wood of the cue, not allowing a player to feel as well if the shot was shot as intended. Note: all cue sticks are made of wood. But if it is a graphite or fiberglass cue, it is only the outer layer that is bonded with the inner core of wood. The feel of graphite and fiberglass cues have been criticized by the pool playing community for being very bad in that they are harder to maintain (compared to wood cues) and feel stiff. Because of this, they are usually used as break cues. If the fiberglass or graphite on a cue is scratched, it is rendered unrepairable. Also, after some use, the materials become very glossy and thus not as smooth as they were originally. Wood does not have this problem as it can be sanded or put in a cue lathe. Sanding of a cue shaft is not recommended unless a thinning of its diameter as well as removal of the finish is desired, the only exception being sandpaper so fine, it'll hardly take any wood away. One common way to make a cue run smoothly is to use a damp, then a dry cloth. The rise in the popularity of synthetic materials used is considered much due to the sponsors of professional players, as well as new players thinking that there is an improvement in technology of cues by use of graphite and fiberglass, much like how tennis and golf have used lighter materials. But this is not the case for cues because they must have a specified weight according to the rules, and composite materials do not add significant strength.

Deflection

Also known as "squirt", cue ball deflection is the natural result of stroking with sidespin, or "english". When the cue ball is struck to the left or right of center, it does not go exactly in the direction of the stroke of the cue but rather is deflected offline, making it necessary for the player to compensate. The farther the strike is from the center, the more the cue ball is deflected offline. Cue ball deflection also tends to increase somewhat with a faster stroke, for most cues from 2% to 3% over the normal playing range of 5 mph to 15 mph cue ball speed.

Cues vary widely in how much they deflect the cue ball. The lowest deflecting cue that one billiards retailer has tested has only eliminated about 20% of the deflection caused by the average cue.[10] Lower deflecting shafts require less compensation and many believe this equals greater accuracy, but they also tend to spin the ball more and some feel that means less control. Also there is a period of adjustment to a shaft that performs very differently and some are not willing or able to take the time to change from what has become so familiar over many years.

Pivot points

Each shaft has its own "pivot point" which is directly determined by the amount of cue ball deflection or "squirt" it produces. The calculated pivot point for each shaft is measured from the front of the tip. If one bridges exactly at a shaft's pivot point and holds the bridge very steady, one can pivot the cue by moving one's back hand and no matter where one strikes the cue ball it will track off on the same line as if struck dead center. Pivot points are interesting and may be useful but the player must also consider "swerve" and "throw". Swerve is the tendency of the cue ball to curve slightly in the direction of the applied sidespin, like a mild form of massé. Throw is caused by the friction between the cue ball and the object ball and is much stronger than most realize – for example, if one shoots a straight in shot firmly with left spin and hit the back of the pocket, if a snapshot could be taken at the moment the cue ball contacts the object ball one would see that the balls are actually aligned significantly to the left of the center of the pocket. There is a popular "pivot point test" that uses this sort of straight shot to determine pivot points but because the throw effect was not considered people have been getting wildly inaccurate results. [1][dead link]

Cue maintenance

After prolonged use of a cue, it inevitably loses its perfect smoothness, shape, cleanliness, and feel. Tips usually start to mushroom if they are soft and they start to hold less chalk. Ferrules become the "blue-ring" infested house cues in pool halls and bars. Shafts develop a distinguished blue tint and aren't as smooth as when they were new. The glossy and shiny parts of the cue become dull, oily, and full of fingerprints. Wraps develop scents of smoke and sweat, and may even start to disentangle and come loose. The butts of cues may start to rattle and the bumpers on the end may be absent.

Tip

Various tools are used to maintain the domed shape of the tip and its rough texture, enabling enough chalk to be held on the surface. First trim the edges of the mushrooming excess leather that is over the diameter of the ferrule with a knife, razor, or specially designed tool. If a tip is left mushroomed, the shots will be less consistent and may lead to more miscues and scratches. Also, imparting spin on the ball is less accurate as opposed to a well-maintained tip. Then reshape with tip shapers (such as Williards Tip Shaper, ATROX tool, sandpaper, or other tools) which reshape the tip to look like the preferred curvature. Finally, use a rougher sandpaper, a tip scuffer, and/or tip pick to roughen and perforate the tip, respectively. Scuffers and sandpaper are known to reduce tip size over time if used too liberally (periodically). That is the reason tip picks were designed; they poke holes into the tip so that there are perforations for chalk to be embedded into. This serves the same purpose in allowing more chalk to be held on the tip. Though these tools are useful, it is not recommended to use them too often. Usually one wants to "tune-up" the tip after it has started to mushroom, or poor performance is noticed, or before an important game such as a tournament. Using tip tools too much decreases the lifetime of the tip. Chalk is naturally abrasive to the tip and if chalked periodically (every turn), it should keep the tip rough enough. Tips should be replaced before its side wears down to not less than 1 mm from the ferrule. Using a tip thinner than this risks damaging the ferrule, a potentially more expensive repair than a new tip. A replacement tip generally costs from 25 cents to $25, excluding an installation service charge, which usually costs $10 or less.

Ferrule

Next item down is the ferrule. If one looks around at most house cues in pool halls and bars, one will notice distinguished blue rings around the ferrule (if the chalk used is blue). This is because of poor chalking technique. Many beginners tend to chalk their cues too hard and in a circular motion. In general this would be ok, but the problem is they do not know when to use a new chalk. Chalk should be replaced when it has a hole that is relatively deep. When people use chalk that has a large hole in it and rotate the chalk in a circular motion, it makes the ring around the ferrule. This ring is usually hard to get rid of unless taken care of early. Different chalks have different stain factors and powdery breakdown that can determine how hard it is to remove the stain. For light stains, one can quickly wipe it away with the fingers or a tissue; it is best to refrain from using damp products near a cue because if moisture gets into the wood it can ruin it due to the expansion and contraction of the water. Certain cleaning products can also be used to clean the stain, but it is best to prevent the stain in the first place. When chalking, one should do a light circular motion as well as scraping the whole chalk cube across points that are not covered well with chalk. Done correctly over a substantial time, the chalk has a shallow hole and is relatively flat. This is because one is chalking lightly and not grinding the chalk into the tip, as well as scraping, so that even if there were high walls around the deep hole, they would wear down after some time.

Shaft

A heavy chalker will usually also have a blue tint shaft (from blue chalk, other colors for other colored chalk). Exceptionally powdery or stainable chalks trickle down from the tip down to the shaft and as one strokes, one spreads the chalk on the shaft and stain it over time. This cannot be helped in some places where it is dirty and players place chalk incorrectly on the table, thus getting it on the hands and table cloth even more. After chalking the cue, one should place the chalk facing up so that the process of putting the chalk down does not fling powdered chalk onto the table, thus lessening the amount that gets on the hands and subsequently on the cue, or put it in a pouch (snooker players). Good chalk etiquette also lessens chalk on the table cloth, which can damage the cloth over time by the balls rolling and carrying chalk with it as it rolls and cuts microfibers in the cloth, eventually giving it a fuzzy feel. Basically it will prolong the life of the pool table as well. To clean the shaft after it has been stained, use a very slightly damp cloth/tissue and wipe it down and then dry it right away. That should remove surface stains, but if the stains have gone without care for a long time, one may need to use very fine sandpaper and/or steel wool, or even a toned down (household)vinegar solution. This will actually remove a tiny layer on the shaft and get rid of the stain, but it will also open up the pores in the wood of the shaft to be more susceptible to future staining or damage, which is why one should burnish the wood to close up the pores. This is a home remedy, and is not as good as a professional cleanup on a cue lathe. These methods are also good for regaining the smoothness lost from dirty hands, chalk, and dirt buildup on the shaft. Another way to keep the shaft clean is to keep the hands clean by washing them frequently, since hands usually get sweaty after playing for a long period of time. Some players like to bring a towel with them to tournaments, allowing for them to wipe their hands as well as wipe down their cue; tissues and napkins work just as well if they are clean. One might even bring two small towels: one wet, the other dry.

Joint

A cue's joint sometimes is not perfectly sealed and can get moisture in the wood if it is exposed. In humid areas with large temperature changes, this might ruin the joints and thus the cue itself. To protect the joints, one can purchase a cue case or joint protectors that cover the joints for added protection. Joints are also a frequent place where grease is attracted, especially in brass versions. To remove this grease, fine wool wire can be used (grade 0-0), or simply Brasso(tm). A bit of graphite (pencil) is put on the male end, to prevent any loud squeeks.

Butt

The butt end of the cue requires the least amount of maintenance because players do not touch it much outside the wrap. A quick wipedown with a slightly damp cloth on the areas with a wood finish (not the wrap) followed by a dry wipedown should get rid of any dirt, oil, and fingerprints. Using a bit of linseed oil prevents it from becoming brittle. The wrap may smell or become loose. The smell is from wherever one plays as well as sweaty or dirty hands. Although it cannot be washed, it can be replaced. As with the other maintenance issues, prevention is better than replacement of a cue part. Certain materials for the wrap fare better than others. For instance, Irish Linen will not loosen like other wrap materials because it gets stronger as it gets wet.

Rattling butts may be due to bad construction or the joint needs some attention. It could also be a loose weight inside the butt, a crack in the butt end or the cue may just require a new tip. It should not affect game play except psychologically.

Preventing the loss of bumper is easy; do not play around with them and they should not come loose. If a bumper does become loose, tighten it up again, possibly using a screwdriver.

Cue care in general

To minimize the risk of warping, a cue stick should not be leaned on its tip against anything, and it should be kept in a place that varies little in temperature. Normally, a cue is kept in a soft or hard cue case for easy transport and protection from moisture, the elements, and sudden temperature changes. An abrasive sandpaper should not be used on a cue with a protective finish, as this will scratch or remove it. Every 12 months or so it is advisable to apply a little raw linseed oil on the shaft and wipe dry after leaving overnight.

In other sports and games

Small cue sticks are also used in the tabletop puck game novuss and other cued variants of carrom.

In deck shuffleboard long cues are used to propel pucks down the court. Unlike billiard cues, but more like the ancestral mace, the shuffleboard cue features a broad head, used for shoving, but not striking. The head is sometimes similar to an elongated croquet mallet, but more commonly it is not unlike a small shovel with an edge that may either be straight, or curved in a half-moon shape to better hold and direct the puck. The implement may be all-wooden, or made of other materials, such as metal, plastic or fiberglass.

See also

References

- ^ a b Shamos, Mike (1999). The New Illustrated Encyclopedia of Billiards. New York: Lyons Press. ISBN 1-55821-797-5.

- ^ "Cue Maker and Cues Glossary". EasyPoolTutor. 2003–2007. http://www.easypooltutor.com/glossary-cat-1.html. Retrieved 2007-12-01.

- ^ a b c d e f g h i j k l m n Everton, Clive (1986). The History of Snooker and Billiards (rev. ver. of The Story of Billiards and Snooker, 1979 ed.). Haywards Heath, UK: Partridge Pr. pp. 8–11. ISBN 1-8522-5013-5.

- ^ Oxford English Dictionary (2nd ed.). Oxford: Oxford U. Pr. 1989. "billiard stick" entry.

- ^ Phelan, Michael (1859). The Game of Billiards. New York: D. Appleton & Co. p. 44.

- ^ a b Kilby, Ronald (May 23, 2009). "So What's a Carom Cue?". CaromCues.com. Medford, OR: Kilby Cues. http://www.caromcues.com/CaromvsPoolCues.htm. Retrieved November 20, 2009.[dead link]

- ^ See online and offline retailers. Virtually all modern snooker cues are 56.5 to 58 inch, with 57 accounting for about 90% of the market (of major manufacturers, only Peradon default to 58). Weights range from 17 to 19 ounces (0.48–54–kg) High-end cues are almost always compatible with one or more butt extension types, and often include one.

- ^ Mataya Laurance, Ewa; Thomas C. Shaw (1999). The Complete Idiot's Guide to Pool & Billiards. New York: Alpha Books. p. 79. ISBN 0-02-862645-1.

- ^ CueMuseum.com

- ^ "Deflection Ratings". http://www.platinumbilliards.com/rating_deflect.php. Retrieved 2008-06-01.

External links

- The Cue Museum - An online museum dedicated to important works from notable and important cue stick makers throughout history. Also a resource for collectors featuring articles as well as cue stick history.

- The American Cuemakers Association - An organization dedicated to promoting pool cues as a unique collectible art form.

Categories:- Snooker equipment

Wikimedia Foundation. 2010.