- Gas centrifuge

-

A gas centrifuge is a device that performs isotope separation of gases. A centrifuge relies on the principles of centripetal force accelerating molecules so that particles of different masses are physically separated in a gradient along the radius of a rotating container. A prominent use of gas centrifuges is for the separation of uranium-235 from uranium-238. The gas centrifuge was developed to replace the gaseous diffusion method of uranium-235 extraction. High degrees of separation of these isotopes relies on using many individual centrifuges arranged in cascade, that successively achieve higher concentrations. This process yields higher concentrations of uranium-235 while using significantly less energy compared to the gaseous diffusion process.

Contents

Centrifugal process

The centrifuge relies on the force resulting from centripetal acceleration to separate molecules according to their mass, and can be applied to most fluids.[1] The dense (heavier) molecules move towards the wall and the lighter ones remain close to the center. In addition, if one creates a thermal gradient in a perpendicular direction by keeping the top of the rotating column cool and the bottom hot, the resulting convection current carries the lighter molecules to the top while the heavier ones settle at the bottom, from which they can be continuously withdrawn.

In practice, several such centrifuges are connected in series. Each centrifuge receives one input and produces two output lines, corresponding to light and heavy fractions. The input of each centrifuge is the output (heavy) of the previous centrifuge and the output (light) of the following stage. This produces an almost pure light fraction from the output (light) of the first centrifuge and an almost pure heavy fraction from the output (heavy) of the last centrifuge.

Gas centrifugation process

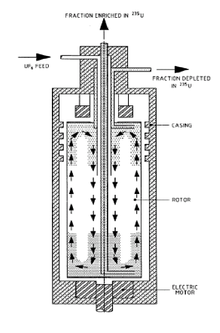

The gas centrifugation process utilizes a unique design that allows gas to constantly flow in and out of the centrifuge. Unlike most centrifuges which rely on batch processing, the gas centrifuge utilizes continuous processing, allowing cascading, in which multiple identical processes occur in succession. The gas centrifuge consists of a cylindrical rotor, a casing, an electric motor, and three lines for material to travel. The gas centrifuge is designed with a casing that completely encloses the centrifuge.[2] The cylindrical rotor is located inside the casing, which is evacuated of all air to produce a near frictionless rotation when operating. The motor spins the rotor, creating the centripetal force on the components as they enter the cylindrical rotor. There are two output lines, one located at the top of the centrifuge and the other located at the bottom. The heavier molecules will segregate to the bottom of the centrifuge while the lighter molecules will segregate to the top of the centrifuge. The output lines take these separations to other centrifuges to continue to the centrifugation process.[3]

Separative work units

The separative work unit (SWU) is a measure of the amount of work done by the centrifuge and has units of mass (typically kilogram separative work unit). The work WSWU necessary to separate a mass F of feed of assay xf into a mass P of product assay xp, and tails of mass T and assay xt is expressed in terms of the number of separative work units needed, given by the expression

- where

is the value function, defined as

is the value function, defined as

Practical application of centrifugation

Separating Uranium-235 from Uranium-238

The separation of uranium requires the material in a gaseous form; uranium hexafluoride (UF6) is used for uranium enrichment. Upon entering the centrifuge, the lighter uranium-235 isotope collects towards one end of the centrifuge while the heavier uranium-238 isotope at the other. The enriched uranium is sent upstream to another centrifuging stage and the depleted uranium downstream to the previous stage. Usually, enrichments plants may include thousands of centrifuges arranged in cascades.

Separation of zinc isotopes

For some uses in nuclear technology, the content of zinc-64 in zinc metal has to be lowered in order to prevent formation of radioisotopes by its neutron activation. Diethyl zinc is used as the gaseous feed medium for the centrifuge cascade. An example of a resulting material is depleted zinc oxide, used as a corrosion inhibitor.

History

Suggested in 1919, the centrifugal process was first successfully performed in 1934. Jesse Beams and coworkers at the University of Virginia developed the process by separating two chlorine isotopes through a vacuum ultracentrifuge. It was one of the initial isotopic separation means pursued during the Manhattan Project, but research was discontinued in 1944 as it was felt that the method would not produce results by the end of the war, and that other means of uranium enrichment (gaseous diffusion and electromagnetic separation) had a better chance of success in the short term. However this method was successfully used in the Soviet nuclear program, making the Soviet Union the most effective supplier of enriched uranium.

In the long term, especially with the development of the Zippe-type centrifuge, the gas centrifuge has become a very economical mode of separation, using considerably less energy than other methods and having numerous other advantages. Enrichment by centrifuge has been used in particular by Abdul Qadeer Khan in Pakistan, and the method was smuggled to at least three different countries by the end of the 20th century.[2]

See also

Footnotes

References

- "Basics of Centrifugation." Cole-Parmer Technical Lab. 14 Mar. 2008

- "Gas Centrifuge Uranium Enrichment." Global Security.Org. 27 Apr. 2005. 13 Mar. 2008

- "What is a Gas Centrifuge?" 2003. Institute for Science and International Security. 14 Mar. 2008

External links

Categories:

Wikimedia Foundation. 2010.