- Governor (device)

-

For other uses, see governor (disambiguation).

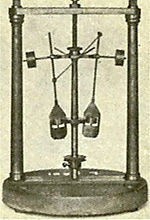

A governor, or speed limiter, is a device used to measure and regulate the speed of a machine, such as an engine. A classic example is the centrifugal governor, also known as the Watt or fly-ball governor, which uses a rotating assembly of weights mounted on arms to determine how fast the engine shaft is spinning, and then uses proportional control to regulate the shaft rotational speed.

Contents

History

Centrifugal governors were used to regulate the distance and pressure between millstones in windmills since the 17th century. Early steam engines employed a purely reciprocating motion, and were used for pumping water – an application that could tolerate variations in the working speed. It was not until the Scottish engineer James Watt introduced the rotative steam engine, for driving factory machinery, that a constant operating speed became necessary. Between the years 1775 and 1800, Watt, in partnership with industrialist Matthew Boulton, produced some 500 rotative beam engines. At the heart of these engines was Watt’s self-designed "conical pendulum" governor: a set of revolving steel balls attached to a vertical spindle by link arms, where the controlling force consists of the weight of the balls.

Building on Watt’s design was American engineer Willard Gibbs who in 1872 theoretically analyzed Watt’s conical pendulum governor from a mathematical energy balance perspective. During his Graduate school years at Yale University, Gibbs observed that the operation of the device in practice was beset with the disadvantages of sluggishness and a tendency to overcorrect for the changes in speed it was supposed to control.[1]

Gibbs theorized that, analogous to the equilibrium of the simple Watt governor (which depends on the balancing of two torques: one due to the weight of the “balls” and the other due to their rotation), thermodynamic equilibrium for any work-producing thermodynamic system depends on the balance of two entities. The first is the heat energy supplied to the intermediate substance, and the second is the work energy performed by the intermediate substance. In this case, the intermediate substance is steam. These sorts of theoretical investigations culminated in the 1876 publication of the Gibbs' famous work On the Equilibrium of Heterogeneous Substances and in the construction of the Gibbs’ governor, shown adjacent. These formulations are ubiquitous today in the natural sciences in the form of the Gibbs' free energy equation, which is used to determine the equilibrium of chemical reactions; also known as Gibbs equilibrium.[2]

Example uses

- On aircraft propellers the governor senses shaft rpm, and adjusts or controls the angle of the blades to vary the torque load on the engine. Thus as the aircraft speeds up (as in a dive) or slows (in climb) the RPM is held constant.

- A Pneumatic governor mechanism senses air flow from the flywheel blower used to cool an air-cooled engine. The typical design includes an air vane mounted inside the engine's blower housing and linked to the carburetor's throttle shaft. A spring pulls the throttle open and as the engine gains speed, increased air flow from the blower forces the vane back against the spring, partially closing the throttle. Eventually a point of equilibrium will be reached and the engine will run at a relatively constant speed. Pneumatic governors are simple in design and inexpensive to produce. However, they do not regulate engine speed very accurately and are affected by air density, as well as external conditions that may influence airflow.

- Centrifugal flyweight mechanism driven by the engine is linked to the throttle and works against a spring in a fashion similar to that of the pneumatic governor, resulting in essentially identical operation. A centrifugal governor is more complex to design and produce than a pneumatic governor. However, the centrifugal design is more sensitive to speed changes and hence is better suited to engines that experience large fluctuations in loading.

- Electronic servo motor is linked to the throttle and controlled by an electronic module [disambiguation needed

] that senses engine speed by counting electrical pulses emitted by the ignition system or a magnetic pickup. The frequency of these pulses varies directly with engine speed, allowing the control module to apply a proportional voltage to the servo to regulate engine speed. Due to their sensitivity and rapid response to speed changes, electronic governors are often fitted to engine-driven generators designed to power computer hardware, as the generator's output frequency must be held within narrow limits to avoid malfunction.

] that senses engine speed by counting electrical pulses emitted by the ignition system or a magnetic pickup. The frequency of these pulses varies directly with engine speed, allowing the control module to apply a proportional voltage to the servo to regulate engine speed. Due to their sensitivity and rapid response to speed changes, electronic governors are often fitted to engine-driven generators designed to power computer hardware, as the generator's output frequency must be held within narrow limits to avoid malfunction.

See also

- Speed limiter

- Regulator

- Servomechanism

- Hit and miss engine

References

- ^ Wheeler, Lynder Phelps (1947), "The Gibbs Governor for Steam Engines", in Wheeler, Lynder Phelps; Waters, Everett Oyler; Dudley, Samuel William, The Early Work of Willard Gibbs in Applied Mechanics, New York: Henry Schuman, pp. 63–78

- ^ Wheeler, L. (1951). Josiah Willard Gibbs - the History of a Great Mind. Woodbridge, CT: Ox Bow Press.

External links

Categories:- Mechanisms

- Mechanical power control

Wikimedia Foundation. 2010.