- Sinking (metalworking)

-

Sinking, also known as doming, dishing or dapping, is a metalworking technique whereby flat sheet metal is formed into a non-flat object by hammering it into a concave indentation. While sinking is a relatively fast method, it results in stretching and therefore thinning the metal, risking failure of the metal if it is 'sunk' too far.

Sinking is used in the manufacture of many items, from jewellery to plate armour.

Technique

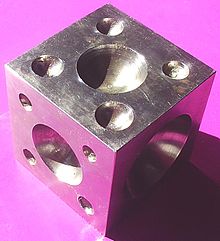

Sinking is performed by using a curved hammer or mallet-driven punch to force sheet metal into an indentation. The exact nature of these tools will vary greatly depending on the scale and nature of the work. Fine work will typically require a small doming punch and a doming block. Larger work may involve a special sinking hammer and sinking stump. The forming indentation need not be permanent; metal can be sunk into sandbags or lead blocks.

Sinking may be done when the metal is cold or hot. If a piece is extensively worked cold, it will work harden and require annealing to prevent cracking.

It also may be useful to planish the metal to smooth it out.

References

- Finegold, Rupert and William Seitz. Silversmithing. Krause; 1983. ISBN 0-8019-7232-9

- Price, Brian R. Techniques of Medieval Armour Reproduction. Boulder, CO: Paladin Press, 2000. ISBN 1-58160-098-4

Metalworking Forming, fabrication, and finishing General Forming processes Coining · Drawing · Electrohydraulic forming · Electromagnetic forming · Explosive forming · Forging · Hydroforming · Progressive stamping · Punching · Rolling · Sinking · Spinning · Swaging · Tube bendingJoining processes Finishing processes Anodizing · Galvanizing · Heat treatment · Mass finishing · Patination · Peening · Plating · PolishingCasting · Fabrication · Forming · Jewellery · Machining · Metallurgy · Smithing · Tools and terminology · Welding Categories:- Metal forming

- Jewellery making

Wikimedia Foundation. 2010.