- Chemical looping combustion

-

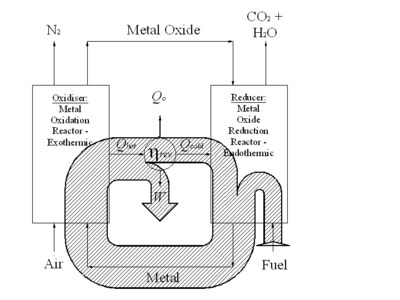

Chemical looping combustion (CLC) typically employs a dual fluidized bed system (circulating fluidized bed process) where a metal oxide is employed as a bed material providing the oxygen for combustion in the fuel reactor. The reduced metal is then transferred to the second bed (air reactor) and re-oxidized before being reintroduced back to the fuel reactor completing the loop.

Isolation of the fuel from air simplifies the number of chemical reactions in combustion. Employing oxygen without nitrogen and the trace gases found in air eliminates the primary source for the formation of nitrogen oxide (NOx), producing a flue gas composed primarily of carbon dioxide and water vapor; other trace pollutants depend on the fuel selected.

Contents

Description

Chemical looping combustion (CLC) uses two or more reactions to perform the oxidation of hydrocarbon based fuels. In its simplest form, an oxygen carrying species (normally a metal) is first oxidised in air forming an oxide. This oxide is then reduced using a hydrocarbon as reducer in a second reaction. As an example, a nickel based system burning pure carbon would involve the two redox reactions:

- 2Ni(s) + O2(g) → 2NiO(s)… (1)

- C(s) + 2NiO(s) → CO2(g) + 2Ni(s)… (2)

If (1) and (2) are added together, the reaction set reduces to straight carbon oxidation – the nickel acting as a catalyst only i.e.:

- C(s) + O2(g) → CO2(g)… (3)

CLC dates from the early 1980s when it was proposed as a system for increasing power station efficiency [1]. The gain in efficiency is possible due to the enhanced reversibility of the two redox reactions; in traditional single stage combustion, the release of a fuel’s energy occurs in a highly irreversible manner - departing considerably from equilibrium. In CLC, if an appropriate oxygen carrier is chosen, both redox reactions can be made to occur almost reversibly and at relatively low temperatures. Theoretically, this allows a power station using CLC to approach the ideal work output for an internal combustion engine without exposing components to excessive working temperatures.

Fig 1 illustrates the energy exchanges in a CLC system graphically, and shows a Sankey diagram of the energy fluxes occurring in a reversible CLC based engine. Studying Fig 1, a heat engine is arranged to receive heat at high temperature from the exothermic oxidation reaction. After converting part of this energy to work, the heat engine rejects the remaining energy as heat. Almost all of this heat rejection can be absorbed by the endothermic reduction reaction occurring in the reducer. This arrangement requires the redox reactions to be exothermic and endothermic respectively, but this is normally the case for most metals [2]. Some additional heat exchange with the environment is required to satisfy the second law; theoretically, for a reversible process, the heat exchange is related to the standard state entropy change, ΔSo, of the primary hydrocarbon oxidation reaction as follows:

Qo = ToΔSo

However, for most hydrocarbons ΔSo, is a small value and, as a result, an engine of high overall efficiency is theoretically possible.[3].

Although proposed as a means of increasing efficiency, in recent years, interest has been shown in CLC as a carbon capture technique. Carbon capture is facilitated by CLC because the two redox reactions generate two intrinsically separated flue gas streams: a stream from the oxidiser, consisting of atmospheric N2 and residual O2, but sensibly free of CO2; and a stream from the reducer containing CO2 and H2O with very little diluent nitrogen. The oxidiser exit gas can be discharged to the atmosphere causing minimal CO2 pollution. The reducer exit gas contains almost all of the CO2 generated by the system and CLC therefore can be said to exhibit 'inherent carbon capture', as water vapour can easily be removed from the second flue gas via condensation, leading to a stream of almost pure CO2. This gives CLC clear benefits when compared with competing carbon capture technologies, as the latter generally involve a significant energy penalty associated with either post combustion scrubbing systems or the work input required for air separation plants. This has led to CLC being proposed as an energy efficient carbon capture technology [4][5].

In summary CLC can achieve both an increase in power station efficiency simultaneously with low energy penalty carbon capture. Challenges with CLC include operation of dual fluidized bed (maintaining carrier fluidization while avoiding crushing and attrition), and maintaining carrier stability over many cycles.

See also

- Combustion

- Oxy-fuel combustion

- Oxidizing agent

- Redox (reduction/oxidation reaction)

- Carbon capture and storage

- Lane hydrogen producer

References

- ^ Richter, H.J. and Knoche, K.F. (1983). Reversibility of combustion processes, in Efficiency and Costing – Second law analysis of processes.. ACS symposium series. pp. 71–85.

- ^ Jerndal, E., Mattisson, T. and Lyngfelt, A. (2006). "Thermal analysis of chemical-looping combustion". Trans IChemE, Part a Chem. Eng. Res. And Des. 84: 795–806. doi:10.1205/cherd05020.

- ^ McGlashan, N.R. (2008). "Chemical looping combustion – a thermodynamic study". Proc. IMechE, Part C: J. Mech. Eng. Sci. 222: 1005–1019. doi:10.1243/09544062JMES790.

- ^ Ishida, M., and Jin, N. (1997). "CO2 Recovery in a power plant with chemical looping combustion". Energy Conv. Mgmt. 38: S187–S192. doi:10.1016/S0196-8904(96)00267-1.

- ^ Brandvoll, Ø. and Bolland, O. (2004). "Inherent CO2 capture using chemical looping combustion in a natural gas fired cycle". Trans. ASME 126: 316–321.

External links

Categories:- Combustion

- Chemical processes

- Chemical engineering

Wikimedia Foundation. 2010.