- Cerium hexaboride

-

Cerium hexaboride  Other namescerium boride, ceBIX, CEBIX

Other namescerium boride, ceBIX, CEBIXIdentifiers CAS number 12008-02-5 EC number 234-526-9 - InChI=1/B6.Ce/c1-2-3(1)5(1)4(1,2)6(2,3)5;/q-2;+2

Properties Molecular formula CeB6 Molar mass 204.986 g/mol Density 4.80 g/cm3 Melting point 2552 °C, 2825 K, 4625 °F

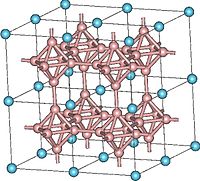

Solubility in water insoluble Structure Crystal structure Cubic Space group Pm3m ; Oh  hexaboride (verify) (what is:

hexaboride (verify) (what is:  /

/ ?)

?)

Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa)Infobox references A cerium hexaboride top hat cathode. Image courtesy of Applied Physics Technologies

Cerium hexaboride (CeB6, also called cerium boride, CeBix, CEBIX, and (incorrectly) CeB) is an inorganic chemical, a boride of cerium. It is a refractory ceramic material. It has low work function and one of the highest electron emissivity known, and is stable in vacuum. The principal use of cerium hexaboride is a coating of hot cathodes, or hot cathodes made of cerium hexaboride crystals. It usually operates at temperature of 1450 °C.

Lanthanum hexaboride (LaB6) and cerium hexaboride (CeB6) are used as coating of some high-current hot cathodes. Hexaborides show low work function, around 2.5 eV. They are also somewhat resistant to cathode poisoning. Cerium boride cathodes show lower evaporation rate at 1700 K than lanthanum boride, but it becomes equal at 1850 K and higher above that. Cerium boride cathodes have one and half the lifetime of lanthanum boride, due to its higher resistance to carbon contamination. Boride cathodes are about ten times as "bright" than the tungsten ones and have 10-15 times longer lifetime. In some laboratory tests, CeB6 has proven to be more resistant to the negative impact of carbon contamination than LaB6. They are used eg. in electron microscopes, microwave tubes, electron lithography, electron beam welding, X-Ray tubes, and free electron lasers.

Cerium hexaboride, like lanthanum hexaboride, slowly evaporates during the cathode operation. In conditions where CeB6 cathodes are operated under 1850 K, CeB6 should maintain its optimum shape longer and therefore last longer. While the process is about 30% slower than with lanthanum boride, the cerium boride deposits are reported to be more difficult to remove.[1]

References

Cerium compounds CeB6 · CeBr3 · Categories:

- Cerium compounds

- Borides

- Refractory materials

- Ceramic materials

Wikimedia Foundation. 2010.

Look at other dictionaries:

Lanthanum hexaboride — Chembox new ImageFile = ImageSize = IUPACName = OtherNames = lanthanum boride Section1 = Chembox Identifiers CASNo = 12008 21 8 PubChem = SMILES = Section2 = Chembox Properties Formula = LaB6 MolarMass = 203.776 g/mol Appearance = intense purple… … Wikipedia

Hot cathode — is also a name for a hot filament ionization gauge, a vacuum measuring device.In vacuum tubes, a hot cathode is a cathode electrode which emits electrons due to thermionic emission. ( Cf. cold cathodes, where field emission is used and which do… … Wikipedia

Dictionary of chemical formulas — This is a list of chemical compounds with chemical formulas and CAS numbers, indexed by formula. This complements alternative listings to be found at list of inorganic compounds, list of organic compounds and inorganic compounds by element. Table … Wikipedia

Samarium — promethium ← samarium → europium ↑ Sm ↓ … Wikipedia