- Mortar and pestle

-

Mortar and Pestle

A simple kitchen mortar and pestleOther names Mortar Grinder Uses Grinding

MixingRelated items Mill A mortar and pestle is a tool used to crush, grind, and mix solid substances (trituration). The pestle is a heavy bat-shaped object, the end of which is used for crushing and grinding. The mortar is a bowl, typically made of hard wood, ceramic or stone. The substance to be ground is placed in the mortar and ground, crushed or mixed with the pestle.

Contents

Etymology

The English word mortar derives from classical Latin mortarium, meaning, among several other usages, "receptacle for pounding" and "product of grinding or pounding". The classical Latin pistillum, meaning "pounder", led to English pestle. The Roman poet Juvenal applied both mortarium and pistillum to articles used in the preparation of drugs, reflecting the early use of the mortar and pestle as a pharmacist's or apothecary's symbol.[1] The antiquity of these tools is well documented in early literature, such as the Egyptian Ebers Papyrus of ~1550 BCE (the oldest preserved piece of medical literature) and the Old Testament (Numbers 11:8 and Proverbs 27:22).[2]

Medical use

Mortars and pestles were traditionally used in pharmacies to crush various ingredients prior to preparing an extemporaneous prescription. The mortar and pestle, along with the Rod of Asclepius, the Green Cross, and others, is one of the most pervasive symbols of pharmacology,[3] along with the show globe. For pharmaceutical use, the mortar and the head of the pestle are usually made of porcelain, while the handle of the pestle is made of wood. This is known as a Wedgwood mortar and pestle and originated in 1779. Today the act of mixing ingredients or reducing the particle size is known as trituration. Mortars and pestles are also used as drug paraphernalia to grind up pills to speed up absorption when they are ingested, or in preparation for insufflation.

Food preparation

Mortars are also used in cooking to prepare ingredients such as guacamole, gazpacho and pesto (which derives its name from the pestle pounding), as well as grinding spices into powder. The molcajete, a version used by pre-Hispanic Mesoamerican cultures including the Aztec and Maya, stretching back several thousand years, is made of basalt and is used widely in Mexican cooking. It likely evolved from the more primitive metate grinding slab. Other Native American tribes used mortars carved into the bedrock to grind acorns and other nuts. Many such depressions can be found in their former territories.

In Japan, very large mortars are used with wooden mallets to prepare mochi. A regular sized Japanese mortar and pestle are called a suribachi and surikogi, respectively. Granite mortars and pestles are used in Southeast Asia, as well as Pakistan and India. In India, it's used extensively to make spice mixtures for various delicacies as well as day to day dishes. With the advent of motorized grinders, use of the mortar and pestle has decreased. It is traditional in various Hindu ceremonies (such as weddings, and upanayanam) to crush turmeric in these mortars. In Malay, it is known as lesung. Large stone mortars, with long (2–3 feet) wood pestles were used in West Asia to grind meat for a type of meatloaf, or kibbeh, as well as the hummus variety known as masabcha.

Material

Good pestle and mortar-making materials must be hard enough to crush the substance rather than be worn away by it. They cannot be too brittle either, or they will break during the pounding and grinding. The material should also be cohesive, so that small bits of the mortar or pestle do not get mixed in with the ingredients. Smooth and non-porous materials are chosen that will not absorb or trap the substances being ground. In food preparation, a rough or absorbent material may cause the strong flavor of a past ingredient to be tasted in food prepared later. Also, the food particles left in the mortar and on the pestle may support the growth of microorganisms. When dealing with medications, the previous prepared drugs may interact or mix, contaminating the currently used ingredients.

Rough ceramic mortar and pestle sets can be used to reduce substances to very fine powders, but stain easily and are brittle. Porcelain mortars are sometimes conditioned for use by grinding some sand to give them a rougher surface which helps to reduce the particle size. Glass mortars and pestles are fragile, but stain-resistant and suitable for use with liquids. However, they do not grind as finely as the ceramic type.

Other materials used include marble, stone, wood (highly absorbent), bamboo, iron, steel, brass and basalt. Mortar and pestle sets made from the wood of old grape vines have proved reliable for grinding salt and pepper at the dinner table. Uncooked rice is sometimes ground in mortars to clean them. This process must be repeated until the rice comes out completely white. Some stones, such as molcajete, need to be seasoned first before use. Metal mortars are kept lightly oiled.

Automatic mortar grinder

Since the results obtained with hand grinding are neither reproducible nor reliable, most laboratories work with automatic mortar grinders. Grinding time and pressure of the mortar can be adjusted and fixed, saving time and labor.

The first automatic Mortar Grinder was invented by F. Kurt Retsch in 1923 – the "Retschmill".[4]

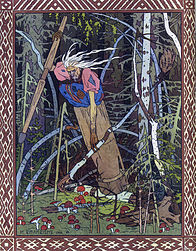

Folklore

In Russian tales, Baba Yagá is portrayed as a hag who flies through the air in a mortar, using the pestle as a rudder.

See also

References

- ^ Satire VII line 170: et quae iam ueteres sanant mortaria caecos. (and the mortars that cure old blind men)

- ^ www.usip.edu The mortar and pestle from the renaissance to the present

- ^ Pharmaceutical Symbols, Museum of the Royal Pharmaceutical Society of Great Britain. Page 2. Retrieved 2009-10-21.

- ^ Retsch: Size reduction with mortar grinders and disc mills. Rose Scientific Ltd. Retrieved 2009-10-21.

External links

Categories:- Food grinding tools

- Alchemical tools

- Laboratory porcelainware

- Laboratory equipment

Wikimedia Foundation. 2010.