- Mine railway

-

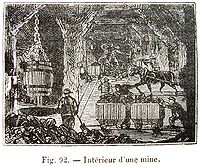

A mine railway is a railway constructed to carry materials and workers in and out of a mine.[1] Materials transported typically include ore, coal and spoil. Today most mine railways are electrically powered; in former times pit ponies, such as Shetland ponies, were used to haul the trains. In very cramped conditions, children were also used.

Contents

General

Mine wagon on wooden rails at Siebenbürgen, end of the 19th century

There is usually no direct connection from a mine railway to the mine's industrial siding or the public railway network, because of the narrow gauge track that is normally employed. This reduces the size and scale of the trucks used, called a Dram, and hence increases access, meaning that they can be taken closer to the mining face.

Original mine railways used wax-impregnated wooden rails attached to wooden sleepers, on which drams were dragged by men, children or animals. This was later replaced by L-shaped iron rails, which were attached to the mine floor, meaning that no sleepers were required and hence leaving easy access for the feet of children or animals to propel more drams.

Pit ponies

A preserved Dandy wagon of the Ffestiniog Railway. Before locomotives, slate trains would travel down to Porthmadog under gravity, and be pulled back up by horses

A preserved Dandy wagon of the Ffestiniog Railway. Before locomotives, slate trains would travel down to Porthmadog under gravity, and be pulled back up by horses Main article: Pit pony

Main article: Pit ponyThe Romans were the first to realise the benefits of using animals in their industrial workings, using specially bred pit ponies to power supplementary work such as mine pumps.

Ponies began to be used underground, often replacing child or female labour, as distances from pit head to coal face became greater. The first known recorded use in Britain was in the County Durham coalfield in 1750; however, the use of ponies never made it to the mines of the United States. At the peak in 1913, there were 70,000 ponies underground in Britain. In later years, mechanical haulage was quickly introduced on the main underground roads replacing the pony hauls and ponies tended to be confined to the shorter runs from coal face to main road (known in North East England as "putting") which were more difficult to mechanise. As of 1984, 55 ponies were still at use with the National Coal Board in Britain, chiefly at the modern pit in Ellington, Northumberland.

Dandy wagons were often attached to trains of full drams, to contain a horse or pony. Mining and later railway engineers designed their tramways so that full (heavy) trains would use gravity down the slope, while horses would be used to pull the empty drams back to the workigs. The Dandy wagon allowed for easy transportation of the required horse each time.

Probably the last colliery horse to work underground in a British coal mine, Robbie, was retired from Pant y Gasseg, near Pontypool, in May 1999.[2]

Combustion-engined operation

19th and early 20th century mine railway locomotives were operated with petrol benzene and alcohol / benzene mixtures.[3] Although such engines were probably preferred in metal mines, firedamp safety has been achieved by special types of motors and special exhaust system with cooling water injection, and mesh, chipboard or disc protection over the exhaust openings. These filters contribute greatly to reducing noxious fumes.

For safety (flammability of the fuel) modern mine railway locomotives are only operated using diesel fuel.

Battery operations

Trainload of chrome ore emerging from a mine tunnel at the Ben Bow chromite mine in Stillwater County, Montana

Trainload of chrome ore emerging from a mine tunnel at the Ben Bow chromite mine in Stillwater County, Montana

Battery powered locomotives and systems solved many of the potential explosive problems that combustion engines provided, and also emitted fewer gases within mines. However, batteries are heavy items which require long periods of charge to produce relatively short periods of full-power operation, resulting in either restricted operations or the need for the doubling-up of equipment purchasing. Hence while popular, battery systems were often practically restricted to mines where systems were short, and moving relatively low-density ore which could explode easily.

Catenary operations

Mine locomotive U 28 from AEG at the Verein Rothe Erde, Esch-sur-Alzette 1894

Mine locomotive U 28 from AEG at the Verein Rothe Erde, Esch-sur-Alzette 1894

The electric motor technology used pre-1900 to DC with a few hundred volts and a direct supply of power to the motor from the catenary enabled the use of efficient, small and sturdy tractors of simple construction. This met the needs of mine railways very well, especially for underground working and so the use of electrically powered trains soon became widespread on mine railways.

The first electric mine railway in the world was developed by Siemens & Halske for stone coal mining in Saxon Zauckerode near Dresden (now Freital) and was being worked as early as 1882 on the 5th main cross-passage of the Oppel Shaft run by the Royal Saxon Coal Works.

In 1894, the mine railway of the Aachen smelting company, Rothe Erde, was electrically driven, as were subsequently numerous other mine railways in the Rhineland, Saarland Lorraine, Luxembourg and Belgian Wallonia. There were large scale deliveries of electric locomotives for these railways from AEG, Siemens & Halske, Siemens-Schuckert Works (SSW) and the Union Electricitäts-Gesellschaft (UEG) in these countries.

Explosion-proof mining locomotives from Schalker Eisenhütte are used in all the mines owned by Ruhrkohle (today Deutsche Steinkohle).

Compressed-air operation

Compressed-air locomotives were powered by compressed air that were carried on the locomotive in compressed-air containers. This method of propulsion had the advantage of being safe but the disadvantage of high operating costs.

In operation

Until 1995 the largest single, narrow gauge, above-ground, mine and coal railway network in Europe was in the Leipzig-Altenburg lignite field in Germany. It had 726 kilometres of 900 mm track - the largest 900 mm network in existence. Of this, about 215 kilometres was removable track inside the actual pits and 511 kilometres was fixed track for the transportation of coal to the main rail network.

The last 900 mm gauge mine railway in the German state of Saxony, a major mining area in central Europe, was closed in 1999 at the Zwenkau Mine in Leipzig. Once a very extensive railway network, towards the end it only had 70 kilometres of movable 900 mm track and 90 kilometres of 900 mm fixed railway track within the Zwenkau open cast mine site itself, as well as a 20-kilometre, standard gauge, link railway for the coal trains to the power stations (1995–1999). The closure of this mine marked the end of the history of 900 mm mine railways in the lignite mines of Saxony. In December 1999, the last 900 mm railway in the Central German coal mining field in Lusatia was closed.

Mine railways as museum and heritage railways

A remnant of the coal railways in the Leipzig-Altenburg Lignite Field may be visited and operated as a museum railway. Regular museum trains also run on the line from Meuselwitz via Haselbach to Regis-Breitingen.

References

External links

Categories:- Rolling stock

- Mining equipment

- Mining engineering

- Industrial railways

Wikimedia Foundation. 2010.