- Directional solidification

-

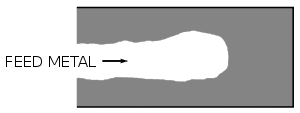

Directional solidification and progressive solidification describe types of solidification within castings. Directional solidification describes solidification that occurs from farthest end of the casting and works its way towards the sprue. Progressive solidification, also known as parallel solidification,[1] is solidification that starts at the walls of the casting and progresses perpendicular from that surface.[2]

Contents

Theory

Most metals and alloys shrink as the material changes from a liquid state to a solid state. Therefore, if liquid material is not available to compensate for this shrinkage a shrinkage defect forms. When progressive solidification dominates over directional solidification a shrinkage defect will form.[2]

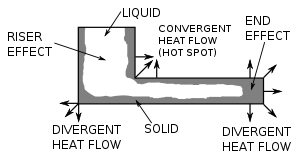

The geometrical shape of the mold cavity has direct effect on progressive and directional solidification. At the end of tunnel type geometries divergent heat flow occurs, which causes that area of the casting to cool faster than surrounding areas; this is called an end effect. Large cavities do not cool as quickly as surrounding areas because there is less heat flow; this is called a riser effect. Also note that corners can create divergent or convergent (also known as hot spots) heat flow areas.[3]

In order to induce directional solidification chills, risers, insulating sleeves, control of pouring rate, and pouring temperature can be utilized.[4]

Directional solidification can be used as a purification process. Since most impurities will be more soluble in the liquid than in the solid phase during solidification, impurities will be "pushed" by the solidification front, causing much of the finished casting to have a lower concentration of impurities than the feedstock material, while the last solidified metal will be enriched with impurities. This last part of the metal can be scrapped or recycled. The suitability of directional solidification in removing a specific impurity from a certain metal depends on the partition coefficient of the impurity in the metal in question, as described by the Scheil equation. Directional solidification is frequently employed as a purification step in the production of multicrystalline silicon for solar cells.[citation needed]

References

- ^ Stefanescu 2008, p. 67.

- ^ a b Chastain 2004, p. 104.

- ^ Stefanescu 2008, p. 68.

- ^ Chastain 2004, pp. 104–105.

Bibliography

- Chastain, Stephen (2004), Metal casting: a sand casting manual for the small foundry, Vol. II, 4, Stephen Chastain, ISBN 9780970220332, http://books.google.com/books?id=3O5kqZww24gC.

- Stefanescu, Doru Michael (2008), Science and Engineering of Casting Solidification (2nd ed.), Springer, ISBN 9780387746098, http://books.google.com/books?id=JVTJi30phCwC.

Further reading

- Campbell, John, Castings (2nd ed.), Butterworth-Heinemann, ISBN 0750647906.

- Wlodawer, Robert (1966), Directional solidification of steel castings, Pergamon Press.

Metalworking Casting Processes Centrifugal · Continuous · Die · Evaporative-pattern (Lost foam and Full mold) · Investment (Lost wax) · Permanent mold · Plaster mold casting · Sand · Semi-solid metal · Shaw process · Shell molding · SpinComponents Terminology Casting · Fabrication · Forming · Jewellery · Machining · Metallurgy · Smithing · Tools and terminology · Welding Categories:- Casting (manufacturing)

Wikimedia Foundation. 2010.