- Mopani Copper Mine

-

Mopani Copper Mines Plc Type Public Company Industry Mining, Materials Founded N/A Headquarters Kitwe, Zambia Key people Emmanuel B Mutati, CEO Products Copper, Cobalt Revenue N/A Employees 15,500 total Website N/A Mopani Copper Mines PLC (“Mopani”) is a Zambian registered company owned by Carlisa Investments Corporation (a joint venture company comprising Glencore International AG (73.1%) and First Quantum Minerals Ltd (16.9%)) and ZCCM-IH (10%).[1] Minority shareholders are spread throughout the world in various locations.[2]

Mopani Mines produces and sells copper and cobalt to the international market.

Contents

Overview

The Company has mine sites at Mufulira and Nkana, which are located on the Copperbelt in Zambia. The Corporate Head Office is established in Kitwe and lies adjacent to the Nkana assets. Nkana has been in operation since 1931 and Mufulira, which has been in operation since 1933 lies 50 kilometres north of Kitwe.

The Company operates the Mufulira mine, smelter, concentrator and copper refinery and the Nkana mine, concentrator and cobalt plant.[3] The name “Mopani” was chosen by vote amongst employees. The Mopani tree is an indigenous Zambian hard wood with a long life and is extremely resilient.

History

Mopani Copper Mines Plc was originally part of the Zambia Consolidated Copper Mines Limited (ZCCM Ltd) entity, being state owned until privatisation in 2000.[4]

On April 1, 2000, Mopani purchased the Zambia Consolidated Copper Mines Limited (“ZCCM”) assets at Mufulira consisting of Underground Mine, Concentrator, Smelter, and Refinery and at Nkana, which include the Underground Mines, Concentrator and Cobalt Plant from the Government of the Republic of Zambia (GRZ).

Following privatisation the Zambian Government retained a stake in the mining industry through ZCCM Investments Holdings Plc (ZCCM-IH) which is an investments holdings company, quoted on the Lusaka, London, and Euronext Stock Exchanges, and has the majority of its investments held in the copper mining sector of Zambia.

It was important for a name to be found that retained the acronym “MCM” after privatization, because MCM is the London Metal Exchange listed name for copper produced at Mufulira Refinery. Mufulira copper is considered amongst the purest copper in the world.

MCM produced 134,800 tonnes of copper and 2,040 tonnes of cobalt in 2003.[5] At that time, MCM invested in a number of oxide copper projects at several of its properties, including an in-situ leaching project at Mufulira and leaching at Nkana, and has achieved significant production increases at its underground mining operations in Kitwe and Mufulira. Copper production from internal sources was supplemented by the purchase of some 18,000 tonnes of copper in high-grade oxide concentrate bought from the Democratic Republic of the Congo, and 185,325 tonnes of copper concentrate toll treated from Copper-miner Equinox in 2007.[6]

The company installed ISA smelt furnace, Matte Settling Electric Furnace, Oxygen plant, at the Mufulira smelter during 2004 and 2005, at a total cost of US$ 213 million.

The Mopani Copper Mine has generated over $380 million in tax payments to the Zambian government since privatization in 2000 through royalties, import/customs duties and income taxes.[7]

Mufulira Mine

Mufulira used to be the largest mine in Africa employing around 10,000. Presently the Mufulira Mine currently employs 5,000 people. Assets; includes a concentrator, a refinery and a smelter; and produces 35,000 tonnes of contained copper in ore each year through the process of open stopping. The copper is then taken to the concentrator.

There are three types of mining methods currently in use at Mufulira mine site. The first is the original drill and blast underground mining method (MCR – Mechanised Continuous Retreat or modified Sub Level Caving) used in Mufulira main, secondly Room and Pillar with waste rock backfill employed at Mufulira East Portal, and thirdly Insitu Leaching of old stopes.

Mufulira Concentrator

The Concentrator operates in a conventional manner, and has a capacity of 8,500 tonnes of ore per day. Primary stage crushing of ore is done underground while the secondary and tertiary stage crushing take place at the Concentrator. Ball mills grind the crushed ore for subsequent flotation to produce a copper concentrate grade of 40-43%. Concentrator recovery is approximately 94.5%.

Mufulira Smelter

The smelter smelts the copper concentrate mixed with silica in the Isasmelt furnace.[8] The product from the ISA furnace is matte and slag which goes to the Matte Settling Electric Furnace. Slag is tapped out and discarded. Matte is tapped out and taken to the PS converters for further processing to blister copper. The blister copper is then further processed in Anode furnaces and, thereafter, the copper is cast into anodes in a twin casting wheel. The anodes are then sent to the Refinery for electro-refining.[9]

The Mufulira smelter was first built in 1937. Prior to privatization in 2000, 100% of all SO2 went into the atmosphere, and the latest information confirms that the situation has improved since, including notably through the investment financed by EIB’s loan to Mopani copper mine for modernization of the copper smelter. The project has successfully established the capacity to eliminate 170,000 tonnes of SO2 a year, materially contributing to the protection of the environment.[10]

Mufulira Refinery (including Agitation Leach, Heap Leach, SX & EW Plants)

In the Refinery copper anodes coming from the Smelter are electro-refined to produce cathodes having 99.99 % Cu and conforming to LME grade A. This is done by putting anodes and cathodes alternately in a cell, in which copper sulphate electrolyte solution is circulated and current is passed. Copper ions thus generated from anodes move towards cathode and get deposited on starter plates [cathodes]. The cathode plates are taken out from the cells at a certain interval. The cathodes thus produced are bundled and are mostly exported.

During electrolysis precious metals like Gold, Silver, Platinum, selenium, palladium etc. settle down along with other impurities at the bottom of the cells. This is removed and collected at the end of anode cycle. This product known as Anode Slime is washed, dried packed and exported for recovering precious metals.

At the Refinery there are also three SX Plants and one Electro-winning Plant. PLS from the Agitation Leach, Mufulira West heap leach and In-Situ Leach operations are first treated at SX Plants and then taken to the Electro-wining Plant for the production of copper cathodes.

Mopani Mine Mine head Gear - South ore Body at Nkana.Molten copper being poured at Mufulira.New shower and toilet blocks under construction.Leach Ponds - Mufilira.Milling Hall.Smelter control room.Nkana Mine

Nkana mine is one of the largest in Africa,[11] a copper mine located 1km south-west of Kitwe.

At Nkana, copper and cobalt ore is produced from five sources: Four underground mines namely: Mindola North Shaft, Mindola Sub Vertical Shaft, Central Shaft, South Ore Body (SOB) Shaft and Open Pits dotted across the Nkana Oxide Cap. Vertical crater retreat (VCR), both caving and post-fill, have been the predominant mining method utilised within the Nkana mine, but is now being converted to a combination of sub-level caving (SLC) and open stoping techniques.

Vertical shafts from the surface provide access to each of the four underground mines. In addition, in the deeper sections of the Mindola mine and Central Shaft, sub vertical shafts extend services to the 5500L and 3580L respectively.

The Nkana mine has been in operation since 1932[12] and has produced 6,000,000 tonnes of copper so far. Its reserves underground include 108,145,000 tonnes of ore at 1.83% copper and 0.12 cobalt.*

Copper and cobalt mineralisation occur within the ore shale.[13] Copper mineralisation in the deposits changes from mostly chalcopyrite in the South Orebody, to chalcopyrite-bornite in the Central area and to bornite-chalcopyrite at Mindola. Cobalt occurs as carrollite and cobaltiferous pyrite in approximately equal proportions. The mine produces copper and cobalt from three sources: Mindola Shaft, Central Shaft and South Orebody Shaft. Vertical crater retreat is the predominant mining method while sublevel open-stopping and sublevel caving methods are also used.[14]Other metallurgical facilities, under a management contract by an affiliate of the Anglo American Group at privatisation, include the Nkana smelter (not owned by Mopani), acid plant (not owned by Mopani) and copper refinery (not owned by Mopani). There is extensive mine tailings around this mine.

In April 2011 Mopani announced its intentions to sink a new $295million shaft at Mufulira, this should extend the life of the mine by some twenty-five years.[15] The synclinorium shaft will have a production capacity of 115 million tonnes of copper ore.[16] Once commissioned in the first quarter of 2015 it will create about 600 jobs.

Nkana Concentrator

The Nkana Concentrator is located in Kitwe and treats copper-cobalt sulphide ore using a bulk flotation and segregation flotation flowsheet to produce separate copper and cobalt concentrates. The Nkana Concentrator is the most important mineral processing unit of Mopani, as it contributes to produce high purity cobalt metal.

Nkana Cobalt Plant

The cobalt plant treats the cobalt concentrates to produce high purity cobalt metal.[17]

Mopani Social & Community Involvement

MCM is spending around US$16-20 million per year on social projects which includes: operating two hospitals and seven township clinics, five first-aid centres and public health departments at Nkana and Mufulira. Mopani also runs two schools for 1,850 pupils, HIV and malaria prevention and control programmes, supports local orphanages, charities and sports clubs. Retired miners have also been supplied with opportunities for post-retirement employment at a Mopani supported farm near Mufulira.[18]

Education

Mopani continues to offer high standards of education at its schools. At the time of vesting in the year 2000, the Mopani schools namely MCM Nkana School and MCM Mufulira School, were primary schools (up to grade 7) but beginning 2005, Mopani increased its investment in the schools resulting in the addition of two secondary schools, i.e. one in Kitwe and the other in Mufulira. The schools have a total population of 1,847 pupils — both employees’ and community members’ children, who are selected on merit. These schools are amongst the best on the Copperbelt both in terms of infrastructure and performance. The annual average cost of running the schools is US$1.5 million. Besides investments in its own schools, the Company gives various awards to students at institutions of higher learning and in some cases prizes for pupils in primary and secondary schools for academic excellence. The company has also been instrumental in rehabilitating infrastructure in some public institutions - the most recent project being the rehabilitation of infrastructure at a Government school in Kitwe. The works included building of a perimeter wall, construction of a new ablution block, rehabilitation of an old ablution block and installation of a water tank all at a cost of USD 54, 000.00.

Health

Mopani owns and operates two ISO 9001:2008 certified hospitals, the Malcolm Watson hospital in Mufulira and the Wusakile Hospital[19] in Kitwe. It also runs seven township clinics and five first aid centres with complementary fully fledged public health facilities at both Nkana and Mufulira respectively.[20] Activities include the implementation of the integrated malaria control programmes (since October 2000), and HIV/AIDS programmes (since January 2003) at both Nkana and Mufulira respectively. Mopani continues to pursue a plan to ensure long-term control of malaria and HIV prevention at district, provincial and national levels in collaboration with other stakeholders.

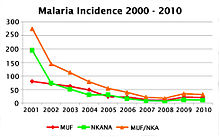

The services at the seven clinics within the nearby communities have gone a long way in enhancing child and maternal health and hence reducing the hospital admission rates by 60%. With regard to the catchment population, Mopani’s health facilities provide medical and public health services to close to 95,000 people with Mufulira accounting for a third of this total number. The integrated malaria programme aims at reducing the incidence rate from about 216/1000 population in October 2000 when the programme commenced to less than 20/1000 population within Mopani’s catchment areas. The population covered is 60,446 and 34,065 at Nkana and Mufulira respectively. The average annual expenditure on the malaria programme is US$650,000.00.

The chart below indicates the incidence trend during the period under review:

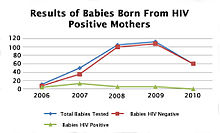

Mopani developed an HIV/AIDS Policy in 2002 and commenced its programme implementation in January, 2003. The HIV/AIDS[21] Programme aims at influencing behavioural change among employees and the immediate community to prevent new infections and the incidence of HIV. In addition to the above, the programme has a treatment and care component as well. This programme has been conducted in collaboration with partners including Comprehensive HIV/AIDS Programme Management (CHAMP), AIDSRelief as well as the Zambian Government through the Ministry of Health. The number of persons enrolled on treatment increased from 24 in 2004 to 7,300 by April 2011 (including 600 children) at all the company’s medical facilities. Increased access to antiretroviral therapy has enhanced the quality of life and in turn reduced incidences of morbidity and mortality among individuals on treatment.

Most encouraging of the interventions is the Prevention of Mother to Child Transmission (PMTCT),[22] with a notable downward trend of babies testing positive in spite of being born to HIV positive mothers. Additionally availability at work for employees on treatment has improved as their condition has been well managed. Most of the treatment and prevention costs on the HIV programme are incorporated in the medical costs. However, there is a component of training of the HIV programme team members in line with the Company’s HIV policy where an average of US$60,000.00 is spent per annum.

Support to Former Employees

Former employees have been provided with opportunities for post-retirement employment and notable among them is at a Mopani supported farm near Mufulira.

The 1,300 hectare farm plot was acquired at the end of 2004 and was managed as a project for 106 former employees with their respective dependants under the supervision of a Farm Manager employed by Mopani until August 2010. The former employees were assisted in forming a Cooperative whose activities include growing of bananas, bee keeping, poultry and dairy farming, piggery and vegetable growing.[23]

During the period of the project - from acquisition of the land to the full implementation of a running Cooperative, Mopani spent approximately US$1million. The company continues to help as and when assistance is required.

Public Roads

Since inception in April 2000, Mopani has helped with the maintenance of public roads, and in particular the Sabina/Mufulira road. In the years prior to 2011, expenditure on roads averaged US$320,000 per annum and this was largely to mend potholes. However, effective May 2011, Mopani commenced major road works to rehabilitate four public roads namely Central, Mindolo and Chibuluma roads in Kitwe, which will be followed by Sabina/Mufulira road at a cost of US$ 10.5 million.Urban Roads Facelift - The Long Cry Heard, AllAfrica.com 07/06/2011

Sanitation Infrastructure in Wusakile Township

For a long time, the Company has had to contend with high medical costs owing to recurrent typhoid fever in Wusakile Township. This has been due to the continued use of dilapidated communal toilets which were meant for fewer people than the current number of people using them. To overcome this problem, Mopani commenced the construction of 1,500 units of individual sanitation facilities in April 2011 at a cost of US$4.5 million.[24] The project is being carried out in collaboration with the Government of the Republic of Zambia and Nkana Water and Sewerage Company.

Sport

Since inception Mopani has supported Nkana Football Club and Mufulira Wanderers Football Club with a monthly grant. Other sports that receive regular support are rugby, tennis, golf, swimming and occasionally boxing and squash. As regards golf, besides supporting the Nkana and Mufulira Golf Clubs, Mopani has consistently supported the Zambia Open Golf tournaments. The average annual support to sporting activities is US$ 200,000.00.[25]

Other Areas of Support

Mopani supports a number of other social causes on an ad hoc basis, such as traditional ceremonies and deserving charitable organisations both financially and materially depending on the need. Notable on some of the support rendered in the past is the donation of grain worth US$ 5 million to the GRZ during the 2005 drought.

Social Investment US$,000 2002 2033 2004 2005 2006 2007 2008 2009 2010 Total Hospitals & Clinics 4,837 5001 6,173 6,866 9,235 13,782 18,485 9,114 11,117 84,646 Donations 142 156 105 215 *5,368 330 129 63 160 6,668 Schools 453 531 767 1,338 1,621 2,343 2,746 1,092 1,967 12,858 Maleria 213 234 395 545 767 1,236 1,289 266 759 5,704 Roads 0 318 343 374 434 387 384 418 200 2,858 Sport 111 135 229 279 348 213 283 34 150 1,782 HIV/AIDS 0 0 0 136 171 123 43 15 915 1,403 Farms Ex Workers 0 0 178 172 198 341 180 0 0 1,069 Total 5,792 6,375 8,190 9,925 18,142 18,755 23,539 11,002 15,268 116,988 *Includes US$ 5m Zambia and the World Copper Market

In Zambia, Africa's top copper producer, the copper industry is estimated to represent more than half of the country’s GDP, and plays a crucial role in enabling economic development.

Zambia has vast high-grade reserves of the metal used in power and construction. The majority of the copper deposits in Zambia are found along the “Copperbelt” a 500 million year old mountain chain, which hosts world class copper deposits. Its output is expected to more than double from current levels to around 2 million tonnes by 2015.[26]

Copper has had a spectacular run with prices racing ahead to consecutive new highs. Continued strong demand on the back of a recovering world economy, coupled with tight supply, has stoked increasing interest in the market.

At the peak of the recession many western investors either fled or scaled back their presence in the copper belt. This departure of the western investors saw Chinese investors taking up the abandoned positions. In 2009 alone, China invested over $400m into Zambia's mining industry.[27]

The copper belt region is once again thriving, and an astounding $3.6 billion industry beckons in mining-related activities in north-west Zambia. According to some estimates, Zambia is set to become one of the world's top five copper producers by 2013.[28]

References

- ^ Mopani Copper Mine Glencore International Plc. Retrieved 28 July 2011.

- ^ "Brief History of ZCCM-IH" ZCCM Investments Holdings Plc. Retrieved 28 July 2011.

- ^ Mopani Copper Mine Glencore International Plc. Retrieved 28 July 2011.

- ^ "Brief History of ZCCM-IH" ZCCM Investments Holdings Plc. Retrieved 28 July 2011.

- ^ "Mopani spending $560m to triple production" Mining Weekly, 26 August 2005. Retrieved 28 July 2011.

- ^ "Equinox signs final offtake agreements for Zambia copper project" Mining Weekly, 18 July 2007. Accessed 28 July 2011.

- ^ Mopani Copper Project European Investment Bank. 31 May 2011. Retrieved 28 July 2011.

- ^ "Mopani Copper Mines Copper Smelter" First Quantum Minerals. Retrieved 28 July 2011.

- ^ Acid Plant Database Sulphuric-acid.com. Retrieved 28 July 2011.

- ^ Mopani Copper Project European Investment Bank. 31 May 2011. Retrieved 28 July 2011.

- ^ Nkana Mine Mindat.org

- ^ Nkana Mine Miningweekly.com. 3 December 2004. Accessed 28 July 2011.

- ^ Journal of the Geological Society; March 1984 [1]

- ^ Nkana Mine Miningweekly.com. 3 December 2004. Retrieved 28 July 2011.

- ^ "Mopani to spend $ 295 million to sink a shaft at its Nkana mine site" Lusaka Times, 23 April 2011. Retrieved 28 July 2011.

- ^ "Mopani Copper may spend about USD 295 million to sink new shaft at its Nkana mine" Steel Guru, 27 April 2011. Retrieved 28 July 2011.

- ^ Copper Cobalt Mining Plant in Zambia MillExpert.com. Retrieved 28 July 2011.

- ^ Mopani Copper Project European Investment Bank. 31 May 2011. Retrieved 28 July 2011.

- ^ Mopani Copper Mines (Wusakile) Hospital MED Pages. Retrieved 28 July 2011.

- ^ James H. Sablerolles, "Corporate Social (Who's) Responsibility?" Hogeschool Utrecht, July 2010. p.7

- ^ "HIV and AIDS in Zambia" AVERT. Retrieved 28 July 2011.

- ^ "Preventing Mother-to-child Transmission of HIV (PMTCT)" AVERT. Retrieved 28 July 2010.

- ^ James H. Sablerolles, "Corporate Social (Who's) Responsibility?" Hogeschool Utrecht, July 2010. p.8

- ^ Lusaka Times 19 April 2011. Retrieved 28 July 2011.

- ^ James H. Sablerolles, "Corporate Social (Who's) Responsibility?" Hogeschool Utrecht, July 2010.

- ^ "Zambia copper output at 2 mln t by 2015" Reuters Africa, 30 April 2011

- ^ "Chinese to invest at least $400 million in Zambian copper/cobalt ops" Mineweb, 8 June 2009

- ^ "Zambia set to enter world’s top five copper producers" Mining Review, 12 July 2011

Categories:- Mining companies

- Mining in Zambia

Wikimedia Foundation. 2010.