- Traffic barrier

-

Traffic barriers keep vehicles within their roadway and prevent vehicles from colliding with dangerous obstacles. Traffic barriers installed at the road side also prevent errant vehicles from traversing steep (non-recoverable) slopes. Traffic barriers installed at the medians of divided highways are also referred to as median barriers. The latter also prevent errant vehicles from entering the opposing carriageway of traffic and help to prevent head-on collisions.

Contents

Need and placement

Traffic barriers constitute hazards themselves and should only be used when the obstacle poses a greater threat than the barrier itself.[1] In all cases, roadside hazards must be assessed for the danger they pose to traveling motorists based on size, rigidity and distance from the edge of travelway. For instance, small roadside signs and some large signs (ground-mounted breakaway post) often do not merit roadside protection as the barrier itself may pose a greater threat to general health and well-being of the public than the obstacle it intends to protect. In many regions of the world, the concept of clearzone is taken into account when examining the distance of an obstacle or hazard from the edge of travelway.

Clearzone also known as clear recovery area or horizontal clearance[2] is defined (through study) as a lateral distance in which a motorist on a recoverable slope may travel outside of the travelway and return their vehicle safely to the roadway. This distance is commonly determined as the 85th percentile in a study comparable to the method of determining speed limits on roadways through speed studies and varies based on the classification of a roadway. In order to provide for adequate safety in roadside conditions, hazardous elements, whether they be obstacles or steep slopes can be placed outside of the clearzone in order to reduce or eliminate the need for roadside protection.

- Common sites for installation of traffic barrier:

- Bridge ends

- Near steep slopes from roadway limits

- At drainage crossings or culverts where steep or vertical drops are present

- Near large signs/illumination poles or other roadside elements which may pose hazards

When barrier is needed, careful calculations are completed to determine length of need[3] which take into account the aforementioned factors. Specifically, the traffic volumes and therefore, the classification of the roadway in addition to the distance of the hazard from the edge of travelway and the distance or offset of the barrier to be placed or installed from the edge of travelway. It is the case in current times, that barrier or rail that is to be used in construction and maintenance operations has undergone extensive testing in both government and private research facilities in order to determine proper 'crash-worthiness' and effectiveness in conditions which are prescribed for its use. In particular, most roadside protection, whether it be a concrete barrier or rail, or a metal beam fence will perform properly only when placed in adequate proximity to the travelway so as to prevent vehicle impacts at large (obtuse) angles.[4] The method in which a barrier protects motorists from roadside hazards is in how it dissipates the energy of an impact.

Barrier types and performance

Traffic barriers are categorized in two ways: by the function they serve, and by how much they deflect when a vehicle crashes into them.

Barrier functions

Roadside barriers are used to protect traffic from roadside obstacles or hazards, such as slopes steep enough to cause rollover crashes, fixed objects like bridge piers, and bodies of water. Roadside barriers can also be used wide medians, to prevent vehicles from colliding with hazards within the median.

Median barriers are used to prevent vehicles from crossing over a median and striking an oncoming vehicle in a head-on crash. Unlike roadside barriers, they must be designed to be struck from either side.

Bridge barrier is designed to restrain vehicles from crashing off the side of a bridge and falling onto the roadway, river or railroad below. It is usually higher than roadside barrier, to prevent trucks, buses, pedestrians and cyclists from vaulting or rolling over the barrier and falling over the side of the structure. Bridge rails are usually multi-rail tubular steel barriers or reinforced concrete parapets and barriers

Work zone barriers are used to protect traffic form hazards in work zones. Their distinguishing feature is they can be relocated as conditions change in the road works. Two common types are used: temporary concrete barrier and water-filled barrier. The latter is composed of steel-reinforced plasic boxes that are put in place where needed, linked together to form a longitudinal barrier, then ballasted with water. These have an advantage in that they can be assembled without heavy lifting equipment, but they cannot be used in freezing weather.

Barrier stiffness

Barriers are divided into three groups, based on the amount they deflect when struck by a vehicle and the mechanism the barrier uses to resist the impact forces. In the United States, traffic barriers are tested and classified according to the AASHTO Manual for Assessing Safety Hardware (MASH) standards, which recently superseded Federal Highway Administration NCHRP Report 350. Barrier deflections listed below are results from crash tests with a 2000 kg pickup truck traveling 100 km/h, colliding with the rail at a 25 degree angle.[5]

Flexible barriers include cable barriers and weak post corrugated guide rail systems. These are referred to as flexible barriers because they will deflect 1.6 m to 2.6 m when struck by a typical passenger car or light truck. Impact energy is dissipated through tension in the rail elements, deformation of the rail elements, posts, soil and vehicle bodywork, and friction between the rail and vehicle.

Semi-rigid barriers include box beam guide rail, heavy post blocked out corrugated guide rail and thrie-beam[clarification needed] guide rail. They deflect three to six feet: more than rigid barriers, but less than flexible barriers. Impact energy is dissipated through deformation of the rail elements, posts, soil and vehicle bodywork, and friction between the rail and vehicle. Box beam systems also spread the impact force over a number of posts due to the stiffness of the steel tube. These barrier systems deflect up to 1.5 m.

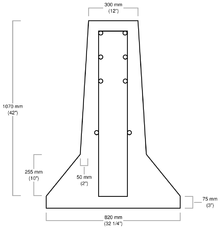

42 inches (110 cm)-high version of the Jersey barrier for deflecting automobiles and semi-trailer trucks.

42 inches (110 cm)-high version of the Jersey barrier for deflecting automobiles and semi-trailer trucks.

Rigid barriers are usually constructed of reinforced concrete. A permanent concrete barrier will only deflect a negligible amount when struck by a vehicle. Instead, the shape of a concrete barrier is designed to redirect a vehicle into a path parallel to the barrier. This means they can be used to protect traffic from hazards very close behind the barrier, and generally require very little maintenance. Impact energy is dissipated through redirection and deformation of the vehicle itself. Jersey barriers and F-shape barriers also lift the vehicle as the tires ride up on the angled lower section. For low-speed or low-angle impacts on these barriers, that may be sufficient to redirect the vehicle without damaging the bodywork. The disadvantage is there is a higher likelihood of rollover with a small car than the single slope or step barriers.[6] Impact forces are resisted by a combination of the rigidity and mass of the barrier. Deflection is usually negligible.

An early concrete barrier design was developed by the New Jersey State Highway Department. This led to the term Jersey barrier being used as a generic term, although technically it applies to a specific shape of concrete barrier. Other types include constant slope barriers, concrete step barriers and F-shape barriers.

Concrete barriers usually have smooth finishes. At some impact angles, coarse finishes allow the drive wheel of front wheel drive vehicles to climb the barrier, potentially causing the vehicle to roll over. However, along parkways and other areas where aesthetics are considered important, reinforced concrete walls with stone veneers or faux stone finishes are sometimes used. These barrier walls usually have vertical faces to prevent vehicles from climbing the barrier.

Barrier end treatments

Early traffic barrier designs often paid little attention to the ends of the barriers. Vehicles that struck blunt ends could stop abruptly or have steel rail sections penetrate into the passenger compartment, resulting in severe injuries or fatalities.[7] As a result, barrier terminals were developed that brought the end of the terminal down to ground level. While this prevented the rail from penetrating the vehicle, it could also vault a vehicle into the air or cause it to roll over, since the barrier end formed a ramp. To address the vaulting and rollover crashes, energy absorbing terminals were developed. These have a large steel impact head that engages the frame or bumper of the vehicle. The impact head is driven back along the guide rail, dissipating the vehicle's kinetic energy by bending or tearing the steel in the guide rail sections. A guide rail may also be terminated by folding it back to the point that the terminal is unlikely to be hit end-on, or, if possible, by embedding the end in a hillside or cut slope.

References

- ^ "Barrier Need". TxDOT RDM. 2010-05-01. http://onlinemanuals.txdot.gov/txdotmanuals/rdw/barrier_need.htm#i1005219. Retrieved 2011-01-11.

- ^ "Cross Sectional Elements". TxDOT RDM. 2010-05-01. http://onlinemanuals.txdot.gov/txdotmanuals/rdw/cross_sectional_elements.htm#BGBGBJBI. Retrieved 2011-01-11.

- ^ "Determining Length of Need of Barrier". TxDOT RDM. 2010-05-01. http://onlinemanuals.txdot.gov/txdotmanuals/rdw/determining_length_of_need_of_barriers.htm. Retrieved 2011-01-11.

- ^ "Placement of Guardrail". TxDOT RDM. 2010-05-01. http://onlinemanuals.txdot.gov/txdotmanuals/rdw/placement_of_guardrail.htm#i1005448. Retrieved 2011-01-11.

- ^ Roadside Design Guide, American Association of State Highway Transportation Officials, 2004, pages 5-10 to 5-23

- ^ Frequently Asked Questions: Barriers, Terminals, Transitions, Attenuators, and Bridge Railings, Federal Highway Administration http://safety.fhwa.dot.gov/roadway_dept/policy_guide/road_hardware/qa_bttabr.cfm#brrs4 accessdate = 2/15/2011

- ^ Roadside Design Guide, American Association of State Highway Transportation Officials, 2004, page 8-1

Categories:- Transport engineering

- Street furniture

- Road infrastructure

- Road transport

- Safety equipment

- Common sites for installation of traffic barrier:

Wikimedia Foundation. 2010.