- Nut (hardware)

-

A nut is a type of hardware fastener with a threaded hole. Nuts are almost always used opposite a mating bolt to fasten a stack of parts together. The two partners are kept together by a combination of their threads' friction, a slight stretch of the bolt, and compression of the parts. In applications where vibration or rotation may work a nut loose, various locking mechanisms may be employed: Adhesives, safety pins or lockwire, nylon inserts, or slightly oval-shaped threads. The most common shape is hexagonal, for similar reasons as the bolt head - 6 sides give a good granularity of angles for a tool to approach from (good in tight spots), but more (and smaller) corners would be vulnerable to being rounded off. Other specialized shapes exist for certain needs, such as wing nuts for finger adjustment and captive nuts for inaccessible areas.

Nuts are graded with strength ratings compatible with their respective bolts; for example, an ISO property class 10 nut will be able to support the bolt proof strength load of an ISO property class 10.9 bolt without stripping. Likewise, an SAE class 5 nut can support the proof load of an SAE class 5 bolt, and so on.

Contents

Types

- Acorn nut (cap nut)

- Barrel nut

- Cage nut

- Clip-on nut (J-nut or U-nut)

- Coupling nut

- Cross dowel

- Flange nut (collar nut)

- Insert nut

- Internal wrenching nut (Allen nut)

- Knurled nut (thumb nut)

- Lug nut

- Nut-type MJT

- Panel nut

- PEM nut (for metal)

- Plate nut (nut plate)

- Rivet nut or blind nut

- Self-aligning nut

- Sex bolt

- Slotted nut

- Split nut

- Sleeve nut

- Square nut

- Staked/welded nut (for plastic)

- Swage nut

- T-nut

- T-slot nut (T-groove) nut

- Weld nut

- Well nut

- Wing nut

Locknuts

- Castellated nut

- Distorted thread locknut

- Centerlock nut

- Elliptical offset locknut

- Toplock nut

- Interfering thread nut

- Tapered thread nut

- Jam nut

- Jet nut (K-nut)

- Keps nut (K-nut or washer nut) with a star-type lock washer

- Nyloc plate nut

- Polymer insert nut (Nyloc)

- Serrated face nut

- Serrated flange nut

- Speed nut (Sheet metal nut or Tinnerman nut)

- Split beam nut

Standard metric hex nuts sizes

nut quotation

nut quotation

Note that flat (wrench) sizes differ from industry standards. For example, wrench sizes of fastener used in Japanese built cars comply with JIS automotive standard.

Nominal diameter

hole D (mm)Pitch

P (mm)Flat size

A/F (mm)External diameter

A/C (mm)Height H (mm) 1st

choice2nd

choicecoarse fine ISO DIN JIS Hex Nut Jam Nut Nylon Nut 1 0.25 2.5 1.2 0.25 1.4 0.3 1.6 0.35 3.2 1.8 0.35 2 0.4 4 1.6 1.2 - 2.5 0.45 5 2 1.6 - 3 0.5 5.5 6.4 2.4 1.8 4 3.5 0.6 6 4 0.7 7 7 7 8.1 3.2 2.2 5 5 0.8 8 8 8 9.2 4 2.7 5 6 1 0.75 10 10 10 11.5 5 3.2 6 7 1 11 5.5 3.5 - 8 1.25 1 13 13 12 15 6.5 4 8 10 1.5 1.25 or 1 16 17 14 19.6 8 5 10 12 1.75 1.5 or 1.25 18 19 17 22.1 10 6 12 14 2 1.5 21 22 19 11 7 14 16 2 1.5 24 24 22 27.7 13 8 16 18 2.5 2 or 1.5 27 15 9 18.5 20 2.5 2 or 1.5 30 30 34.6 16 10 20 22 2.5 2 or 1.5 32 24 3 2 36 41.6 19 27 3 2 41 30 3.5 2 46 53.1 24 33 3.5 2 36 4 3 55 63.5 29 39 4 3 42 4.5 3 45 4.5 3 48 5 3 52 5 4 56 5.5 4 60 5.5 4 64 6 4 Classifications

Mechanical specifications of Metric/English sized nuts[1] Material Proof strength Tensile yield strength (min.) Tensile ultimate strength (min.) Nut marking Nut class ISO 898 (Metric) Low or medium carbon steel 380 MPa (55 ksi) 420 MPa (61 ksi) 520 MPa (75 ksi)

5 Medium carbon steel Q&T 580 MPa (84 ksi) 640 MPa (93 ksi) 800 MPa (116 ksi)

8 Alloy steel Q&T 830 MPa (120 ksi) 940 MPa (136 ksi) 1040 MPa (151 ksi)

10 SAE J995 (English) Low or medium carbon steel 55 ksi (379 MPa) 57 ksi (393 MPa) 74 ksi (510 MPa)

2 Medium carbon steel Q&T 85 ksi (586 MPa) 92 ksi (634 MPa) 120 ksi (827 MPa)

5 Alloy steel Q&T 120 ksi (827 MPa) 130 ksi (896 MPa) 150 ksi (1034 MPa)

8 Manufacture

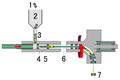

Use of two nuts to prevent self-loosening

In normal use, a nut-and-bolt joint holds together because the bolt is under a constant tensile stress called the preload. The preload pulls the nut threads against the bolt threads, and the nut face against the bearing surface, with a constant force, so that the nut cannot rotate without overcoming the friction between these surfaces. If the joint is subjected to vibration, however, the preload increases and decreases with each cycle of movement. If the minimum preload during the vibration cycle is not enough to hold the nut firmly in contact with the bolt and the bearing surface, then the nut is likely to become loose.

Specialist locking nuts exist to prevent this problem, but sometimes it is sufficient to add a second nut. For this technique to be reliable, each nut must be tightened to the correct torque. The inner nut is tightened to about a quarter to a half of the torque of the outer nut. It is then held in place by a wrench while the outer nut is tightened on top using the full torque. This arrangement causes the two nuts to push on each other, creating a tensile stress in the short section of the bolt that lies between them. Even when the main joint is vibrated, the stress between the two nuts remains constant, thus holding the nut threads in constant contact with the bolt threads and preventing self-loosening. When the joint is assembled correctly, the outer nut bears the full tension of the joint. The inner nut functions merely to add a small additional force to the outer nut and does not need to be as strong, so a thin nut (also called a jam nut) can be used.[2]

See also

- Tapped hole

- Threaded insert

- Washer

References

- ^ Bickford & Nassar 1998, p. 153.

- ^ The Use of Two Nuts to Prevent Self Loosening, Bolt Science Limited, accessed 2011-07-17

Bibliography

- Bickford, John H.; Nassar, Sayed (1998), Handbook of bolts and bolted joints, CRC Press, ISBN 9780824799779, http://books.google.com/books?id=NaZwZK2xm-QC.

External links

Categories:- Threaded fasteners

- Screws

- Fasteners

Wikimedia Foundation. 2010.