- Firestop

-

A firestop is a passive fire protection system of various components used to seal openings and joints in fire-resistance rated wall and/or floor assemblies, based on fire testing and certification listings.

Unprotected openings in fire separations void the fire-resistance ratings of the fire separations that contain them, allowing spread of fire past the limits of the fire safety plan of the entire building. Firestops are designed to restore the fire-resistance ratings of rated wall and/or floor assemblies by impeding the spread of fire through the opening by filling the openings with fire resistant materials.

Contents

Opening types

- Electrical through-penetrations

- Mechanical through-penetrations

- Structural through-penetrations

- Unpenetrated openings (e.g. openings for future use)

- Re-entries of existing firestops

- Control or sway joints within fire-resistance rated wall or floor assemblies

- Junctions between fire-resistance rated wall or floor assemblies

- "Head-of-wall" (HOW) joints, where non-loadbearing wall assemblies meet floor assemblies

-

Fire test of mortar based firestop

-

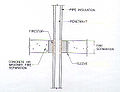

Mechanical pipe with metallic piping through-penetrations in 2 hour concrete floor slab

-

Firestop Mortar seal of an electrical cable tray

Materials

Firestop components include Intumescents, Cementatious mortars, Silicone, Firestop pillows, Mineral fibres, and Rubber compounds.

Ratings

Firestops achieve a fire rating by combining certain materials in an arrangement specific to the item (e.g., pipe, cable) penetrating the fire rated wall or floor, and the construction arrangement of the fire rated wall or floor itself. The materials used in firestops do not have ratings on their own. For instance, a two-hour rated pipe penetration firestop may consist of a layer of caulking over packed rockwool. This overall arrangement provides the 2 hr. rating, not the caulking. However, both the individual firestop materials and the overall firestop assembly are 'listed' per listing and approval use and compliance.

Maintenance

Firestops should be maintained in accordance with the listing and approval use and compliance. Construction documentation sometimes includes an inventory of all firestops in a building, with drawings indicating location and the certification listings of each firestop. Using this documentation, the building owner can meet the requirements of the fire code related to fire barriers during the period of building occupation. Otherwise, improper repairs may result, which would violate the fire code, and could allow a fire to propagate between areas intended by code to be separated during a fire event.

Examples of fire barrier penetrations without firestopping

Older buildings often have no firestops at all. In that case, a thorough inspection can identify all vertical and horizontal fire barriers and their fire ratings, and all breaches in these barriers, which can be sealed approved methods.

-

Improper breach of fire-resistance rated drywall assembly.

Non-listed firestop attempts

Firestops which are created by contractors or building maintenance personnel which are not listed are sometimes referred to as "deemed-to-comply", and are not credited with adequate fire resistance rating for building code compliance purposes. These are short term cost cutting measures at the expense of fire safety and code compliance. Common mistakes include citing a listing for products that may be for other uses. For instance, an insulation with an active listing for having a certain flamespread rating does not mean it is acceptable for firestopping purposes.

-

Polyurethane foam used to fill a cable tray penetration. At Browns Ferry Nuclear Power Plant, a seal of this nature resulted in significant fire losses.

-

Common concrete with no testing intended for certification listing is not a proper firestop.

Re-entry

It is often necessary to the life of the building to install new electrical cables or mechanical systems piping through a hole in a fire rated barrier which has been properly fire stopped during initial construction, in which case the firestops are referred to as being "re-entered". In order to maintain the intent of the original fire protection plan of the building, firestops re-entries must be performed in compliance with the certification listing upon which the original installed configuration was based.

Work sequencing with spray fireproofing

Spray fireproofing of structural steel is most efficiently accomplished before interior partitions are built, which can result in a conflict with fire stops in firewalls. Firestops must adhere to the bare, dry, unobstructed surfaces of the fire barrier which is penetrated (e.g., metal decking), or adjacent to an interface of two fire barriers at which fire stopping is required (e.g., beams). Spray fireproofing cannot be applied prior to fire stopping at these surfaces, as the fireproofing would obstruct adherence of the fire stop materials to the fire barrier surfaces. Spraying the upper room perimeter with fireproofing may also result in covering of wall/ceiling joints and through penetrations that require fire stopping. These joints are then not visually observed and not provided with proper fire stopping, violating the fire integrity of the passive fire barrier.

Tagging

Proper maintenance is enhanced by the installation of tags on each side of the firestop, containing the information necessary to reference to documents indicating the approved procedures for the original installation and re-entries. This requires knowledge of the exact certification listing that was used for each opening, be it a building joint or a penetrant through-penetration seal.

Testing and certification

Acceptable certification listings include but are not limited to those available from

- Underwriters Laboratories, or

- Underwriters Laboratories of Canada in North America, or

- Deutsches Intitut für Bautechnik in Germany, or

- Efectis in The Netherlands, France, Norway.

- FM Global provides testing and certification of firestops, and also certification of firetop contractors[1]

Regulations and compliance

When the installed configuration is not in conformance with the appropriate certification listing, the fire-resistance rating may be less than expected. In those cases in which it is difficult to assess the impact, it often must be assumed to be zero, which means that the fire protection plan for the building is compromised. It is, therefore, necessary to be able to match each opening in fire-resistance rated wall or floor in a building with a certification listing. There are thousands of listings by various certification and testing laboratories. Both the Canadian and US Underwriters Laboratories each publish books containing just their own listings, including only those firestop manufacturers who have contracted with them for testing and certification.

Firestops should be routinely inspected and maintained to mitigate the effects of re-entries and time.

Trade jurisdiction

In North American unionised construction sites, firestopping is often performed by members of the insulating trades[citation needed]. The insulators are the only building trade that includes firestop installation, theory and practical firestop training within its apprenticeship program[citation needed].

An agreement exists between the insulators and the electricians IBEW, which assigns firestop work from electricians to insulators[citation needed], except that composite crews are required when working near live electrical conductors, whereby an electrician is required to observe and ensure the safety of the insulator.

Germany's GBA (Gütegemeinschaft Brandschutz im Ausbau) also offers a passive fire protection course, resulting in a certificate designation: "Brandschutzfachkraft" (~Passive Fire Protection Expert). In Europe as well as North America, all major firestop installers with nuclear installation experience are, by background, insulators first[citation needed]. The generic material types used and the skill sets needed between insulation and firestop installations are similar. Exceptions to the generic rule of thumb about firestopping being insulators' work, includes firestop devices that become an integral part of the plumbing system, which must be installed by plumbers during the forming of concrete.

Trade associations

United States of America:

- Alliance for Fire & Smoke Containment & Control

- Firestop Contractors International Association

- International Firestop Council

See also

- Passive fire protection

- Firestop pillow

- Penetrant

- Penetration (firestop)

- Joint (building)

- Mineral wool

- Mortar (firestop)

- Intumescent

- Endothermic

- Annulus (firestop)

- Product certification

- Certification mark

- Gerald W. Brown

- Silicone foam

- Fireproofing

- Packing (firestopping)

- Sleeve (construction)

- Heat sink

References

- ^ http://www.fmglobal.com/assets/pdf/fmapprovals/4991.pdf Approval Standard for Approval of Firestop Contractors, Class Number 4991

External links

- UL Essay On Firestops

- Deutsches Institut für Bautechnik (DIBt)

- iBMB a part of Technische Universität Braunschweig

- Underwriters' Laboratories of Canada (ULC)

- Underwriters Laboratories

Categories:- Building materials

- Passive fire protection

- Firestops

Wikimedia Foundation. 2010.