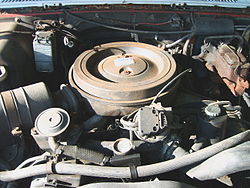

- Detroit Diesel V8 engine

-

Detroit Diesel/General Motors V8 Diesel Manufacturer Detroit Diesel, AM General Production 1982-1993 and 1992-current Predecessor LF9 350 cu in (5.7 L) diesel Successor Duramax V8 engine Displacement 6.2L/379cid and 6.5L/395cid Cylinder bore 6.2L: 3.98 in (101 mm); 6.5L: 4.06 in (103 mm) Piston stroke 6.2L: 3.80 in (97 mm); 6.5L: 3.82 in (97 mm) Cylinder block alloy Iron Cylinder head alloy Iron Valvetrain 16 OHV Compression ratio 21.5:1, Marine 18:1 Turbocharger Borg-Warner GM-X series, also available naturally aspirated Fuel system 1993 And older-Mechanical rotary pump. 1994 And newer-Electronic rotary pump Fuel type Diesel General Motors introduced a line of Diesel V8 engine engines for their C/K pickup trucks in 1982. This engine family, designed by GM division Detroit Diesel, was produced by GM through 2000, when it was replaced by the new Duramax line. AM General's subsidiary General Engine Products (GEP) still produces a military variant of this engine for the HMMWV.[1]

The General Motors light-truck 6.2 and 6.5 L Diesel engines were optional in all 1982 through 2000 Chevrolet and GMC C/K series pickup trucks, Suburbans, Blazer/Jimmy, Tahoe/Yukon, vans, and motor homes. The engine was standard on AM General HMMWV, Hummer H1 and Commercial Utility Cargo Vehicle vehicles. The ready availability and low cost of these engines has made them popular for conversion projects and kit vehicles. These engines are often a popular choice for conversion in Land Rovers, Land Cruisers, and similar vehicles.

Contents

6.2L

The original 6.2 L (379 cu in) Diesel V8 was introduced in 1982 for the Chevrolet/GMC C/K trucks and was produced until 1993. The 6.2L diesel emerged as a high-MPG alternative to the V8 gasoline engine lineup, and achieved better mileage than the General Motors 4.3L V6 gasoline engines of the 80s, at a time when the market was focused on mileage more than power.

Applications

- 1982–1993 Chevrolet/GMC C/K

- 1992 - 1993 AM General Hummer H1

- 198x - 1993 AM General HMMWV

- GM version of the CUCV

- 1982-93 Chevrolet Van

Specifications

- Engine RPO Codes: LH6 ('C' series, with EGR) and LL4 ('J' series)

- Displacement: 6.2L / 379 cu in

- Bore x Stroke: 3.98 × 3.80 in (101 × 97 mm)

- Block / Head: Cast iron / Cast iron

- Aspiration: Natural

- Valvetrain: OHV 2-V

- Compression: 21.5:1

- Injection: Indirect

- Horsepower / Torque (at start): 130 hp (97 kW) @ 3,600 rpm / 240 lb·ft (325 N·m) @ 2,000 rpm

- Horsepower / Torque (at final): 143 hp (107 kW) @ 3,600 rpm / 257 lb·ft (348 N·m) @ 2,000 rpm

- Horsepower / Torque (army): 165 hp (123 kW) @ 3,600 rpm / 330 lb·ft (447 N·m) @ 2,100 rpm

- Max RPMs: 3,600

- Idle RPMs: 650 + or - 25

6.5L

The 6.5 L (395 cu in) version was introduced in 1992 to replace the 6.2. Most 6.5s are equipped with a turbo. This engine was never meant to be a power and torque competitor with Ford/International and Dodge/Cummins, but rather a simple designed workhorse engine that made credible power, achieved decent fuel economy and met emissions standards in half-ton trucks. The Duramax 6600 replaced the 6.5 in light trucks beginning in 2001 and the C3500HD medium duty cab and chassis (replaced by C4500 Kodiak/Topkick) and vans beginning in 2003, but the 6.5 (6500 Optimizer) is still produced by AM General for the HMMWV.

There are several GM 6.5 liter diesel engine production options. The Turbocharged L56, (VIN "S") was used in most 1/2 ton (1500) and light duty 3/4 ton (2500) trucks. One percent of the 1/2 ton (1500) contained a naturally aspirated version of the 6.5. Heavy duty 3/4 ton and 1 ton trucks used the Turbocharged L65 (VIN "F") engine. The L56 is emissions controlled with EGR and catalytic converters. The L65 engine has no EGR, and has no catalytic converter. There is a soot trap on L65 engines that is often mistaken for a catalytic converter. The L49 (VIN "P") and L57 are both naturally aspirated engines. L57 is listed as HO or Heavy Duty. Additional RPO codes are LQM (175HP) and LQN (190HP).

Changes were made by GM to the 6.5 in their light trucks for emissions or reliability improvement. The 1992-1993 model years used a 6.5-specific Stanadyne DB-2 mechanical injection pump. GM replaced the DB-2 with the electronic throttle DS-4 in 1994-2000 vehicles. In mid-1996 GM implemented a redesigned engine cooling system incorporating twin non bypass-blocking thermostats and a 130 GPM water pump. This improved the flow through the block by 70-75% and flow to the radiator 7%.

Applications

- 1994 - 1999 Chevy Blazer/ 2-door Tahoe / GMC Yukon/Chevy K-2500,K-3500

- 1992 - 1999 Chevrolet Suburban / GMC Suburban

- 1992 - 1999 Chevrolet and GMC C/K

- 2000 Chevrolet and GMC C/K 2500 & 3500

- 2001 Chevrolet and GMC C/K 3500

- 1994 - 2004 AM General Hummer H1

- 1994–present AM General HMMWV

Specifications

- Engine RPO Codes: L49, L56, L57, L65, LQM, and LQN.

- Displacement: 6.5L / 397 cu in

- Bore x Stroke: 4.06 x 3.82 (in.)

- Block / Head: Cast iron / Cast iron

- Aspiration: Turbocharged (Borg-Warner GM-X series) Also available naturally aspirated.

- Valvetrain: OHV 2-V

- Compression: GM Early 21.3:1, GM Late 20.3:1, AMG/GEP Marine 18:1

- Injection: Indirect

- Power / Torque (lowest): 180 hp (134 kW) @ 3,400 rpm / 360 lb·ft (488 N·m) @ 1,700 rpm

- Power / Torque (highest): 215 hp (160 kW) @ 3,200 rpm / 540 lb·ft (732 N·m) @ 1,800 rpm

- Max RPMs: 3,400

Common problems

- Main Bearing Web Crack: In both 6.2L and 6.5L engines this is reportedly fixed with a combination of improved higher nickel cast iron alloy and lower block re-design including, but not limited to, a main bearing girdle. These features are in the new for 2007 AM General GEP P400 6500 Optimizer enhanced 6.5L diesel presently being sold to the US Government for the 6 ton armored HMMWV.[1]

- Crank Failure: Related to age failures of the harmonic balancer, the vibration damped accessory drive pulley, or the dual mass flywheel.

- Pump Mounted Driver: Relates to thermal failures. The PMD is screwed to the DS-4 injection pump on the 1994-2001 GM 6.5 diesel utilizing fuel flow to dissipate heat. The injection pump is mounted in the intake valley (a high heat area). The PMD contains two power transistors that should be cooled by proper contact with the injection pump body. If the pump is not precisely machined to make complete contact with the transistors via the silicone thermal gasket and paste, the PMD is improperly installed without the gasket or paste, the PMD is installed off center with the pump body, or corrosion develops on the mounting surface the PMD will overheat. Several companies manufacture an extension harness and heat-sink kits. These allow an owner or their mechanic to relocate the PMD away from the injection pump to a lower heat environment and/or a place that can get more air flow.

- Cylinder Head Cracking: higher mileage 6.5 engines exhibit stress related fractures in the cylinder head bowl. Stronger cylinder heads remedy this problem.

Fuel system

The fuel system on both of these engines relies on a very basic setup. On the 6.2L engines, a camshaft driven mechanical lift pump draws fuel from the tank to the injection pump (also camshaft driven). On 6.5L engines, the lift pump is electrically powered. The injection pump delivers fuel precisely as the injectors need to fire correctly. The fuel system uses Indirect injection and, on 1982-1993 engines, is completely mechanical, much like the Ford 6.9 & 7.3 International Harvester IDI fuel system utilizes. The 1994+ system is similar, but uses the electronically controlled Stanadyne DS4831 series of injection pumps instead of the mechanical DB2831 series found on 1992-1993 6.5's and the DB2829 found on 6.2's.

See also

- List of GM engines

- GM Duramax engine

References

- ^ a b "General Engine Products :: Product Information". AM General. http://www.amgeneral.com/vehicles_gep_productinfo.php. Retrieved 2010-12-02.

External Links

Categories:- GM engines

- Detroit Diesel engines

- Marine diesel engines

- Diesel engines by model

Wikimedia Foundation. 2010.