- Fuse cutout

-

In electrical distribution, a fuse cutout or cut-out fuse is a combination of a fuse and a switch, used in primary overhead feeder lines and taps to protect distribution transformers from current surges and overloads. An overcurrent caused by a fault in the transformer or customer circuit will cause the fuse to melt, disconnecting the transformer from the line. It can also be opened manually by utility linemen standing on the ground and using a long insulating stick called a hot stick.

A cutout consists of three major components:

- The cutout body, an open "C"-shaped frame that supports the "fuse holder" and a porcelain insulator that electrically isolates the conductive portions of the assembly from the support to which the insulator is fastened.

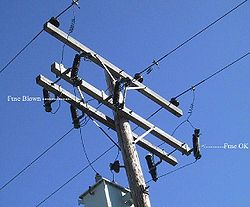

- The fuse holder, often called the "fuse tube" or "door", which contains the interchangeable fuse element and also acts as a simple knife switch. When the contained fuse operates or blows, the fuse holder will drop open, disengaging the knife switch, and hang from a hinge assembly. This hanging fuse holder provides a visible indication that the fuse has operated and assurance that the down-stream circuit is electrically isolated.

- The fuse element, or "fuse link", is the replaceable portion of the assembly that operates due to high electrical currents.

The fuse elements, or fuse links used in most distribution cutouts are tin or silver alloy fuse links that melt (or operate) when exposed to high current conditions. Ampere ratings of fuse elements vary from 1 ampere to 200 amperes.

Cutouts are typically mounted about 20 degrees off vertical so that the center of gravity of the fuse holder is displaced and the fuse holder will rotate by its own weight and dangle when the fuse blows. Tension on the fuse link normally holds an ejector spring in a stable position. When the fuse blows, this tension is released which causes the ejector spring to rapidly pull the unmelted stub of the fuse link out of the fuse holder tube to reduce surge duration and damage to the transformer and fuse holder. This quenches any arc in the fuse holder.

Each fuse holder typically has an attached pull ring that can be engaged by a hook at the end of a fiberglass hot stick operated by a lineworker standing on the ground or from a bucket truck, to manually open the switch. While often used for switching, the standard cutout shown is not designed to be manually opened under load. For applications where the switch is likely to be used to interrupt power manually, a "load break" version is available that has an attachment to quench the arc.

Up until the mid 1990s each manufacturer used their own dimensional standards for cutout design; by the late 1990s most cutouts were of an "interchangeable design". This design allows for the interchangeable use of cutout bodies and fuse holders manufactured by different vendors.

The fuse holder may be replaced by a solid blade, which would allow the fuse holder assembly to be used as a switch only.

If equipped with appropriate mechanism, cutouts can act as sectionalizers, used in combination with autoreclosing circuit breakers. Autoreclosers sense and interrupt brief fault currents and then automatically attempt to restore service a few times (typically 3 or 4); in the meanwhile, (while unenergized) sectionalizer automatically opens in an attempt to isolate the fault from the energy source. After a preset number of operations (such as 3 or 4) the recloser remains open.

External links

- Patent 1,939,371 — 1930 cutout with single hinge

- Patent 2,176,227 — 1932 cutout with double hinge

- Patent 2,519,289 — 1944 cutout with lightning arrestor inside the insulator

- Patent 6,583,708 — recent cutout design

Categories:- Electric power systems components

- Electrical components

- Electric power

- Electric power distribution

Wikimedia Foundation. 2010.