- Copper-silver ionization

-

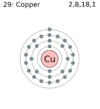

Copper electron shell

Copper electron shell

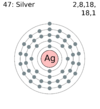

Silver electron shell

Silver electron shell

Copper-silver ionization is an industrial control and prevention process, approved by the U.S. Environmental Protection Agency (as per its Safe Water Drinking Act Lead and Copper Rule limits), against infections of Legionella, the bacteria responsible for legionellosis (Legionnaires' disease).

Contents

Process

Copper-silver ionization is a dispersive process that introduces long-lived, stable, positively charged copper and silver ions into the water system.[1] The ions bond electrostatically with negative sites on bacterial cell walls and denature proteins.[2] Over the long term, ionization thus disperses and destroys biofilms and slimes that can harbor Legionella, the bacteria responsible for legionellosis (Legionnaires' disease).[1] Complete control of a water system can take 30 to 45 days. Flow cells should be cleaned periodically to maintain the system; in a hospital, this task can be delegated to the facility's utility engineers.[3]

Forensic scientist Randy Fornshell of the Sedgwick County Regional Forensic Science Center explains that copper-silver ionization is a modern implementation of the ancient Greek practice of reducing bacteria in wine vessels by lining them with silver, and controlling algae and fungi with copper. Fornshell notes that copper-silver ionization has been effective in swimming pools (it is an alternative to chlorine) and is becoming adopted by larger municipalities.[4]

Replacing chlorination with copper-silver ionization to keep water safe was one response of Frederick Memorial Hospital, Frederick, Maryland, to new requirements in the 2001 Guidelines for Design and Construction of Hospital and Healthcare Facilities, issued by the American Institute of Architects.[5] Ionization is in many cases installed because more convenient and cost-effective than other approaches.[2]

Effectiveness

Ionization is an effective industrial control and prevention process to eradicate Legionella in potable water distribution systems and cooling towers found in health facilities, hotels, nursing homes and most large buildings. In 2003, ionization became the first such hospital disinfection process to have fulfilled a proposed four-step modality evaluation; by then it had been adopted by over 100 hospitals.[2] Additional studies indicate ionization is superior to thermal eradication.[6]

A 2011 study by Lin, Stout and Yu [7][1] found Copper-Silver ionization to be the only Legionella control technology which has been validated through a 4 step scientific approach.

Regulation & Guidelines

Ionization is recognized by the U.S. Environmental Protection Agency (EPA) to control infections of Legionella. The level of ions generated has been reported to be usually below EPA Safe Water Drinking Act Lead and Copper Rule limits.[6] EPA-approved levels of copper or silver in potable water are 1.3 ppm (Cu) and 0.1ppm (Ag). Suboptimal timing of specimen shipment for testing at reference laboratories may contribute to silver concentration above recommendations.[2] Industry leaders who manufacture coper silver ionization technology recommends copper concentration of 0.4 to 0.8 parts per million (ppm) and silver at 40 to 60 parts per billion (ppb), as compliant with EPA drinking water standards.[3]

The British Health and Safety Commission regulates U.K. ionization, advising regular system monitoring to ensure ions reach all water circuits. Also, copper in drinking water is limited to 2 ppm (mg/L) by the European Community whereas Legionella control only requires 0.4 to 0.8 ppm in concentration...well bellow the permissible limits. Headquarters (ECH) in Brussels, Belgium, and silver is not prescribed by the ECH.[1]

Netherlands companies that install and maintain ionization systems have to register with the CTGB [2] (Board for the authorization of pesticides and biocides) and have to comply to Kiwa guidelines. Copper in drinking water is limited to 2 ppm (mg/L) and additionally silver concentrations are limited to 50 ppb (µg/L). [8]

USA maximum copper limits for potable water is set at 1.3ppm whereas EU limitations is 1.0 ppm. Silver limits in the USA is set at 0.1 ppm (100 ppb) yet the EU does not have any guidelines for ionic silver concentrations.

Most industrial or residential ion generators sold around the world do not meet modern commercial fire building codes as a result of the plastic materials that enclose the electrodes. Pressure and temperature limitations are also associated to plastic chamber cells. Plastic ion chamber cells made with materials such as PVC, CPVC, ABS etc... have clear engineering limitations. Industrial type ion chamber cells with the intentions of Legionella control and prevention should be constructed of either powder coated steel or stainless steel engineered for commercial / industrial applications.

See also

External links

Footnotes

- ^ a b c Hayes 2001.

- ^ a b c d Stout & Yu 2003 "(1) Demonstrated efficacy of Legionella eradication in vitro using laboratory assays, (2) anecdotal experiences in preventing legionnaires’ disease in individual hospitals, (3) controlled studies in individual hospitals, and (4) validation in confirmatory reports from multiple hospitals during a prolonged time."

- ^ a b Shields 2002.

- ^ Knapp 2008.

- ^ Sheerin 2003.

- ^ a b Block 2001.

- ^ Lin, Stout & Yu 2011.

- ^ Netherlands National Guidelines 2009.

References

- Yusen E. Lin, PhD, MBA; Janet E. Stout, PhD; Victor L. Yu, MD (2011-2). "Controlling Legionella in Hospital Drinking Water: An Evidence-Based Review of Disinfection Methods". http://www.legionella.org/LinStoutYu2011ICHE.pdf.

- Hayes, John (December 2001). "Copper/silver ionization gaining approval". Professional Carwashing & Detailing 25 (12). http://www.carwash.com/articleprint.asp?print=1&IndexID=6632334. Retrieved 2009-03-02.

- Stout, Janet E., PhD; Yu, Victor L., MD (August 2003). "Experiences of the First 16 Hospitals Using Copper-Silver Ionization for Legionella Control: Implications for the Evaluation of Other Disinfection Modalities". Infection Control and Hospital Epidemiology 24 (8): 563–568. doi:10.1086/502251. PMID 12940575. http://www.liquitech.com/s_case.php. Retrieved 2009-03-02.

- Knapp, Adam (2008-01-25). "Chemist claims water purifying system can save money, health problems". Wichita Business Journal. http://www.bizjournals.com/wichita/stories/2008/01/28/story11.html. Retrieved 2009-03-06.

- Shields, Todd (2002-03-01). "Hospitals turn to ionization method for controlling Legionella infections (What Works)". Healthcare Purchasing News. http://www.accessmylibrary.com/coms2/summary_0286-51804_ITM. Retrieved 2009-03-06.

- Sheerin, Michael, PE (2003-09-01). [tt_news=20399 "Go with the Flow: Midstream Design Changes"]. Consulting-Specifying Engineer. http://www.csemag.com/index.php?id=1398&cHash=081010&tx_ttnews[tt_news]=20399. Retrieved 2009-03-02. "Note about link: URL uses improper characters."

- Block, Seymour Stanton (2001). Disinfection, Sterilization, and Preservation (5th ed.). Lippincott Williams & Wilkins. pp. 423–424. ISBN 9780683307405. http://books.google.com/?id=3f-kPJ17_TYC&pg=PA423&dq=%22copper-silver+ionization%22. Retrieved 2009-03-02.

- "Beoordelingsrichtlijn: Kiwa Netherlands National Guideline BRL". 2009-2-24. http://www.kiwa.nl/upload/BRL/K14010%20-%2001%20-deel%202.pdf.

Categories:- Bacterial diseases

- Industrial hygiene

Wikimedia Foundation. 2010.