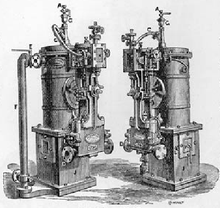

- Chaplin's Patent Distilling Apparatus with Steam Pump

-

Alexander Chaplin & Co. (also known as A.C. and Co., Alex. Chaplin & Co.) was an important and highly regarded[1] engineering and manufacturing syndicate based in the United Kingdom during the mid-19th century to early 20th century with its manufacturing and plant facilities located at Cranstonhill Engine Works, Glasgow. Of their numerous patented and manufactured products, one of the notable devices developed was the Chaplin's Patent Distilling Apparatus with Steam pump for circulating water attached. This was an early design of an evaporator, a device for producing fresh water on board ship by distillation of seawater. An example of this apparatus has been recovered from the wreck of SS Xantho (1872),[2] a steamship used in Australia to transport passengers and trade goods before ultimately sinking in Port Gregory, Western Australia in 1872. It is purported that the Alexander Chaplin distiller from the SS Xantho wreck is the only known surviving example of a Chaplin distilling apparatus on board a steamship of its time.

Contents

History

Founded in 1857, the administrative office of Alexander Chaplin & Co. was located at 63 Queen Victoria Street, London, England,[3] before being taken over by Herbert Morris, LTD in 1932.[4] Well known manufacturers,[5] Alex. Chaplin & Co. prided themselves as “always in stock or in progress”.[6] Chaplins' patent steam engines and boilers powered steam cranes, hoists, locomotives, pumping and winding engines, ship’s deck engines and sea water distilling apparatus throughout the world during the 19th and 20th century. Chaplin's patent sea water distilling apparatus with steam pump attached for circulating water was a very compact and convenient apparatus, used not only for seafaring purposes but on land as well.

The Chaplin Apparatus was adopted by many important British and Continental shipping companies including the Peninsular and Oriental, the Inman, the North German Lloyd, and the Hamburg American Companies. The British Navy used such apparatus’.[5] The Board of Bureau Chiefs of the United States Navy considered supplying the cruisers USS Baltimore (C-3) and USS Philadelphia (C-4) with distilling apparatus to provide fresh water for the boilers from distillation of sea water, but no reference was made to the Chaplin company in their reported discussions.[7] In addition to merchant and passenger ships US gunboats used such distillers as well.[8][9]

Chaplin distillers were also used in land settings. During the Sudan Campaigns (1881–1885), (1896–1899), British forces used the distillers to supply their soldiers with fresh drinking water in Suakin and Sudan. This supply of fresh drinking water was of utmost importance in the 1882 Anglo-Egyptian War. Similar distillers, such as Dr. Normandy's, were on a much larger scale, distilling some 12,000 gallons of water per hour[dubious ],[10] whereas the Chaplin distilling apparatus used onboard vessels produced roughly 23 gallons of fresh water per hour.[11] Essentially, the distilled water produced for Egypt was made in a special apparatus with various forms of condenser employed. The principle for distillation is the same as the apparatus on steamships. On ships, steam is generated in one of the ships boilers then condensed, filtered and aerated in the apparatus. On land, the engines would have to be kept running in order to pump the distilled water out of the condenser.

By the order of H.M. Council on 5 December 1865, Government emigrant, troop and other passenger vessels fitted with this distilling apparatus were permitted to sail with only half the required amount of water under Section 26 of the Passengers Act 1855. This act states “Any passenger ship propelled by sails only, or by steam engines of less power than is sufficient, without the aid of sails, to propel the ship at the rate of five statue miles per hour, may be cleared out and proceed on her voyage, having on board, in tanks or casks, only half the quantity of pure water required by the said Act to be carried for the use of the passengers, provided that…there be on board such ship an efficient apparatus for distilling fresh water from salt water”.[12] This, combined with the convenience and compact size of the apparatus made the Alexander Chaplin model very popular.

In direct competition with Alexander Chaplin, Dr. Alphonse Normandy’s (1809–1864)[13] apparatus is another successful distiller. It consists of three essential parts, the evaporator, the condenser and the refrigerator. The apparatus passes a mixture of steam and gasses from the evaporator to the tubes of the condenser. Normandy’s distiller was very complex in structure, consisting of many numerous working parts. With an elaborate layout and expensive cost, the distiller wasn’t economically plausible from a moderate vessel’s standpoint (book). In France, the apparatus of Rocher and Nantes and that of Galle and Mazeline of Havre, have been "highly appreciated by French authorities and French seamen".[5]

How it works

For successful preparation of potable water from seawater, the following conditions of a distilling apparatus are essential. First, the distilled product must be aerated so it may be immediately available for drinking and storage purposes. Second, the amount of coal used to obtain the maximum volume of drinkable water must be at a minimum expenditure level and third, the apparatus’ working parts must be simple enough to prevent from breaking down and to enable unskilled attendants to safely operate. "The Alexander Chaplin distilling apparatus is among the forms of apparatus which have most fully satisfied such conditions".[5] Commons:File:Chaplin Distilling Apparatus with Key.pdf

The apparatus

The Alexander Chaplin & Co. distilling apparatus is designed for use on board steam vessels and may be connected from the main boiler or a donkey boiler. The apparatus consists of a coiled pipe approximately 60 feet in length placed inside a cylindrical casing. The casing is cast iron and the coils are made of copper. The coils are supplied with steam by one of two methods. Either from the exhaust pipes of the engine, or from a small fitting leading directly from the boiler. A double-acting circulating pump produces a constant stream of water flowing through the condenser, using a pinion that can be disengaged from the crank shaft manually. At the upper end of the coils lie a covered brass cup for ventilating. This aerator is the essential feature in the invention and consists of small adjustable holes around the circumference of the brass cup that allows a pipe to enter the coils. When the apparatus is in action, a jet draws air in from the circumferential openings in the cup and fills the coils with a mixture of air and steam. After passing directly under the condenser, the aerated water is delivered clear, bright and odourless at a temperature of about 13 degrees Celsius. The resulting fresh water is of excellent quality and ready for immediate use. The machine can supply approximately 23 gallons of water per hour. “The samples of water subjected to analysis were collected at different times directly from the Patent Apparatus on board ship… and the results of my experiments with the water distilled in Alexander Chaplin & Co.’s are conclusive in showing that is of excellent quality in every particular.”[14]

The circulating pump of the condensing arrangement can be used as a fire engine in the event of an emergency. The waste pipe from the condenser allows for a cock to be attached, by which way the water can be directed to a fitted union which a hose can be attached. Theoretically, the water would be able to be pumped back into the boiler as well. It is preferred to place the apparatus in the Stokehole or elsewhere below deck, but may be placed on the main deck or any other convenient part of the vessel. In addition to the safety advantages offered by the Chaplin distiller by only having to carry half the amount of water on board it also provided an economic benefit in that the space and weight previously set aside for larger water tanks could be used more productively to carry additional cargo.

According to the manufacturer's specifications and a report generated by Dr. Frederick Penny Ph.D., F.R.S.E Professor of Chemistry, Andersonian University,[15] Glasgow,[14] this distiller filters out noxious chemical such as lead, copper, tin and iron through the use of a series of iron plates with perforated holes and matting. These plates are located in the large box like structure at the bottom of the apparatus.

Precisely when the Chaplin Distiller was installed on the SS Xantho is open to conjecture. It is known that from 1864-1870 the SS Xantho operated out of Wick, West Sussex and was permitted to take excursions to sea. It is possible that this apparatus was installed during this period of time.[16] It is just as feasible however that this device was installed at a later date as part of the major refurbishing programme implemented by the metal merchant Robert Stewart , who is known to have installed a new marine fire tube boiler and a second hand Horizontal Trunk Engine in 1871, designed by John Penn and Son.[17]

Excavation and confirmation of identity

Distiller cannister of SS Xantho

Distiller cannister of SS Xantho

This Chaplin distiller was excavated from the steamship SS Xantho (1872) wreck site in 1994.[18] It was found outside the hull on the port side of the vessel. It is possible that this apparatus was installed on the ship’s deck or in its cabin and as a result of the wreck sites natural transformation has rolled off the deck onto the seabed.

Initially this artefact was considered to be a condenser or a heat exchanger[19] perhaps circle condenser but the discovery of a brass manufacturer's nameplate found whilst de-concreting the object and subsequent archival documentation has confirmed its identity to be a Chaplin distilling apparatus.[11]

On recovery the artefact was found to be in very fragile condition with the cast iron shell badly corroded and incomplete. Additionally there is evidence to suggest that the artefact is missing many of its mountings such as the aerator, connecting pipes and donkey engine. It is inconclusive whether these materials were removed by agents operating under the direction of the owner Charles Edward Broadhurst (1826 – 26 April 1905)[20] in the initial salvaging of the wreck in 1872 or by treasure hunters in more recent times.[21]

Distiller coil from SS Xantho

Distiller coil from SS Xantho

The Chaplin Distiller which was damaged during the excavation and treatment processes is currently being reconstructed at the Western Australian Museum, by the Department of Maritime Archaeology. It is envisaged that this rebuilding process will be completed by 2012 and that it will be available for public viewing in the ‘Steamships to Suffragettes Gallery’ shortly thereafter.

Because of its fragmented state and damage to the coil it is not possible at this stage to provide exact dimensions for this apparatus. A rough estimate would suggest something in the order of 5 foot 3 inches[11] but a definitive answer will be able to be determined once it is reassembled and the coil has been correctly aligned and integrated.

The Chaplin Distilling apparatus excavated from the SS Xantho is believed to be the only known example in existence and therefore can be regarded as a unique piece of maritime history that helps to explain how steamships and sailing vessels fitted with these devices were able to undertake prolonged voyages at sea with a minimal supply of fresh water.

References

- ^ http://www.london-gazette.co.uk/issues/23035/pages/5267/page.pdf

- ^ http://www.museum.wa.gov.au/maritime-archaeology-db/wrecks/xantho

- ^ Alexander Chaplin and Co. (1883). Illustrated Catalogue of Chaplin’s Patent Steam Engines and Boilers: Steam cranes, hoists, locomotives, pumping and winding engines, ship’s deck engines, sea-water distilling apparatus, &c.. London: Alexander Chaplin and Co..

- ^ http://www.nationalarchives.gov.uk/a2a/records.aspx?cat=056-28d69&cid=0#0

- ^ a b c d Baynes, T. (ed.) 1878 The Encyclopaedia Britannica, A dictionary of arts, sciences, and general literature. Ninth edition , Vol.VII New York: New York Charles Scribner’s Sons, pp.263-264.

- ^ Chaplin 1883, p. 3

- ^ The New York Times 1890 Distillers for War Ships. New York: The New York Times 20 August.

- ^ Government Printing Office 1886 Specifications for A Horizontal Back-Acting Compound-Screw Engine for Gunboat No.2, of 870 Tons Displacement to be named the. Washington: Government Printing Office, pp. 37.

- ^ Government Printing Office 1887 Specifications for Two-Horizontal Direct Acting Triple Expansion Screw-Engines for Gunboat No.1, of 1,700 Tons Displacement to be named the. Washington: Government Printing Office, pp. 16.

- ^ Scientific American 1885 The distillation of sea water. Scientific American Supplement No. 492, Scientific American 6 June.

- ^ a b c Chaplin 1883, p. 33

- ^ Kay, J. 1875 The Law relating to Ship masters and Seamen, their appointment, duties, power, rights, liabilities and remedies. Vol.II, Bell Yard, Temple Yard: Stevens and Haynes Law Publishers, pp. 9-12.

- ^ Smith, E. (1905). A Short History of Naval and Marine Engineering. Cambridge: The University Press Cambridge. pp. 223–224.

- ^ a b Chaplin 1883, p. 31

- ^ http://www.strath.ac.uk/archives/ourcollections/ua/omint/m-p/frederickpenny/

- ^ Henderson, G.J and K.J. Henderson 1988 Unfinished Voyages 1850-1880 Vol II. Nedlands: UWA Press.pp. 119-124

- ^ McCarthy, M. (2000). Iron and Steamship Archaeology Success and Failure on the SS Xantho. London: Kluwer Academic / Plenum Publishers. p. 53.

- ^ McCarthy, M. (1996) (Unpublished PhD thesis), SS Xantho: towards a new perspective. An integrated approach to the maritime archaeology and conservation of an iron steamship wreck., Townsville: James Cook University, p. 185

- ^ McCarthy 2000, p. 83

- ^ Black, D. and Bolton, G. 2001 Biographical Register of Members of the Parliament of Western Australia, Volume One, 1870–1930 (Revised Edition ed.). Parliament House: Parliament of Western Australia

- ^ McCarthy 1996, p. 161

Categories:- Evaporators

- Distillation

- Water desalination

- Steam power

- Marine propulsion

Wikimedia Foundation. 2010.