- Boston Manufacturing Company

Infobox_nrhp2 | name =Boston Manufacturing Company

nrhp_type = nhld

nhld = yes

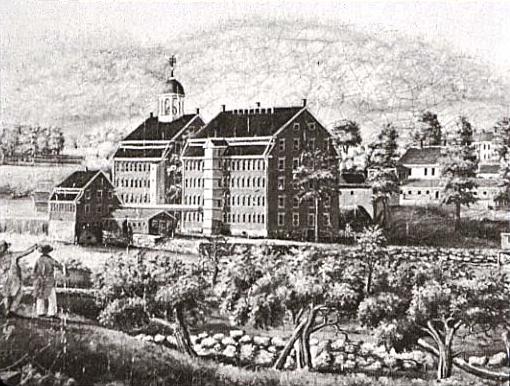

caption = Boston Manufacturing Company, Waltham, Massachusetts

location= 144-190 Moody St.,Waltham, Massachusetts

lat_degrees = 42

lat_minutes = 22

lat_seconds = 23

lat_direction = N

long_degrees = 71

long_minutes = 14

long_seconds = 9

long_direction = W

locmapin = Massachusetts

area =

built =1813

architect= Moody,Paul

architecture= No Style Listed

designated_nhld=December 22 ,1977 cite web|url=http://tps.cr.nps.gov/nhl/detail.cfm?ResourceId=1734&ResourceType=District

title=Boston Manufacturing Company |accessdate=2008-07-15|work=National Historic Landmark summary listing|publisher=National Park Service]

added =December 22 ,1977 cite web|url=http://www.nr.nps.gov/|title=National Register Information System|date=2007-01-23|work=National Register of Historic Places|publisher=National Park Service]

governing_body = Private

refnum=77001412The Boston Manufacturing Company was organized in 1813 by Francis Cabot Lowell, a wealthyBoston merchant, in partnership a group of investors known asThe Boston Associates , for the manufacture of cotton textiles. It is often considered the "Birthplace of the Industrial Revolution in America", since, for the first time all phases of cotton cloth production could be performed under one roof. This would become known as the "Waltham System", an idea that would later be successfully copied atLowell, Massachusetts and several other industrial cities established in the 19th century. It would soon change the face ofNew England and its economy from one based largely on agriculture to one dominated by industry.Origins

Since 1793, when

Samuel Slater established the first successful textile "spinning" mill in America atPawtucket, Rhode Island , harnessed water power had been operating machinery to process cotton fiber into yarn, which would then be outsourced to small weaving shops and private homes where it would be woven into cloth on hand-operated looms. By 1810, dozens of "spinning" mills dotted theNew England countryside. However, cloth production was still fairly slow with this system.While on a visit to

Lancashire ,England in1810 [ [http://www.pbs.org/wgbh/theymadeamerica/whomade/lowell_hi.html Who Made America] ] , Francis Cabot Lowell studied the workings of the successful British textile industry. He paid particular attention to the power loom, a device for which there was yet no equal in America. He knew that increased cloth production in theUnited States depended on such a machine. Upon his return trip toBoston in 1812, he committed the plans to memory, disguising himself as a country farmer, since the British banned export of the new technology at the time. [ [http://www.economicadventure.org/decision/lowell.pdf PDF of Economic Decision-Making: Francis Cabot Lowell] ]In September 1813

The Boston Associates purchased the Boies Paper Mill site in Waltham. With a ten foot drop in the nearbyCharles River , it was an ideal location to establish the new factory they envisioned.Revolution

The group hired a skilled mechanic named Paul Moody of Amesbury to develop and construct the machinery and to supervise the construction of the new mill.

After over a year of trials, Moody was able to bring Lowell's description of the power loom to fruition, making his own advancements along the way. It would be the perfection of Moody's power loom that would be the real "revolution" in American industry. For the first time, all phases of cloth production could be brought under one roof. Moody also developed a system of

power transmission using a series of leather belts and pulleys powered by water turbines, that would prove much more efficient than the shaft and gear system then in use. The first mill was completed in late 1814, after almost a year of construction. Jacob Perkins was in charge of installing the first waterwheel, dam, flumes and raceway.By early 1815, the cloth was sold. Production expanded quickly, as did profits. In 1816 a second larger mill was built next to the first mill. In addition to producing cloth, it also produced textile machinery for other companies. The two mills were later connected in 1843, as part of a planned expansion. cite web|url=http://memory.loc.gov/cgi-bin/ampage?collId=pphhdatapage&fileName=ma/ma0900/ma0972/data/hhdatapage.db&recNum=1&itemLink=D?hh:18:./temp/~pp_VpCJ::

title=Boston Manufacturing Company MA-54|author=George R. Adams, Candace Jenkins, Mike Folsom, Donald C. Jackson |date=1984| accessdate=2008-07-15 |work=Historic American Engineering Record|publisher=Historic American Engineering Record]The power loom was soon and copied my many other

New England area mills, and modified and perfected along the way. Francis Cabot Lowell died in 1817, at age 42.The Waltham System

The Boston Associates attempted to create a well-controlled system of labor which varied from the harsh conditions observed while inLancashire . The mill owners recruited young Yankee farm girls from the surrounding area to come work the machines at Waltham. The mill girls, as they came to be known, lived in boarding houses provided by the company and were supervised by older women, and were subject strict codes of conduct. They worked approximately eighty hours per week. The workers would wake to the factory bell at 4:40 in the morning. They would report to work at 5:00 and have a half hour breakfast break at 7:00 a.m. They would then work until the half hour to forty-five minute lunch break at noon. At 7:00 p.m. the factory would shut down and the workers would return to their company houses. This routine was followed six days a week. This system became known as the Waltham System. [ [http://www.walthammuseum.com/250-history-08.html Local History Pages] ]By the early 1820's the water power of the

Charles River at Waltham was just about maximized, and the investors sought a new location to build even more mills. The Waltham System was then copied at the new city ofLowell, Massachusetts in 1822, but on a much larger scale. The same group of investors would later establishLawrence, Massachusetts ,Manchester, New Hampshire and several other new industrial centers throughout New England during the first half of the 19th century. The factory methods introduced at Waltham would also be copied by other industries in the years to follow.The Waltham site would be expanded again during the late 19th century. The original mills were connected and the gable roofs removed additional floors were added with a flat roofs. The Boston Manufacturing Company closed in 1930.

It was declared a

National Historic Landmark in 1977.citation|title=PDFlink| [http://pdfhost.focus.nps.gov/docs/NHLS/Text/77001412.pdf National Register of Historic Places Inventory-Nomination: Boston Manufacturing Company] |32 KB|date=1977(?) |author=George R. Adams(?) |publisher=National Park Service A National Register of Historic Places Inventory-Nomination document is available upon request from the National Park Service for this site, and should be online but there is an error at the NPS Focus server for this document. However, available are the PDFlink| [http://pdfhost.focus.nps.gov/docs/NHLS/Photos/77001412.pdf "Accompanying six photos, exterior and interior, from 1977"] |32 KB]Today, the site is occupied by apartments, and a small museum.

ee also

*

Francis Cabot Lowell

*Paul Moody

*The Boston Associates External links

* [http://hdl.loc.gov/loc.pnp/hhh.ma0972 Boston Manufacturing Company, 144-190 Moody Street, Waltham, Middlesex County, MA: 70 photos, 15 data pages] , at

Historic American Engineering Record

* [http://www.crmi.org Charles River Museum of Industry]References

Wikimedia Foundation. 2010.