- Cleanroom

-

For the Cleanroom software engineering methodology, see Cleanroom Software Engineering. For the meaning of clean room engineering as a method to avoid copyright infringement, see clean room design.

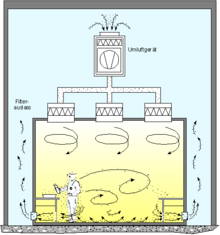

Cleanroom used for the production of microsystems. The yellow lighting is necessary for photolithography, so as to prevent unwanted exposure of photoresist to light of shorter wavelengths.

Cleanroom used for the production of microsystems. The yellow lighting is necessary for photolithography, so as to prevent unwanted exposure of photoresist to light of shorter wavelengths.

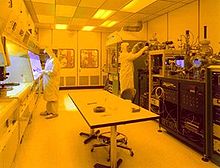

Cleanroom for microelectronics manufacturing

Cleanroom for microelectronics manufacturing

A cleanroom is an environment, typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. More accurately, a cleanroom has a controlled level of contamination that is specified by the number of particles per cubic meter at a specified particle size. To give perspective, the ambient air outside in a typical urban environment contains 35,000,000 particles per cubic meter in the size range 0.5 μm and larger in diameter, corresponding to an ISO 9 cleanroom, while an ISO 1 cleanroom allows no particles in that size range and only 12 particles per cubic meter of 0.3 μm and smaller (see table below).

Contents

Overview

Cleanrooms can be very large. Entire manufacturing facilities can be contained within a cleanroom with factory floors covering thousands of square meters. They are used extensively in semiconductor manufacturing, biotechnology, the life sciences and other fields that are very sensitive to environmental contamination.

The air entering a cleanroom from outside is filtered to exclude dust, and the air inside is constantly recirculated through high-efficiency particulate air (HEPA) and/or ultra-low penetration air (ULPA) filters to remove internally generated contaminants.

Staff enter and leave through airlocks (sometimes including an air shower stage), and wear protective clothing such as hoods, face masks, gloves, boots and coveralls.

Equipment inside the cleanroom is designed to generate minimal air contamination. Even specialised mops and buckets exist. Cleanroom furniture is also designed to produce a minimum of particles and to be easy to clean.

Common materials such as paper, pencils, and fabrics made from natural fibers are often excluded; however, alternatives are available. Cleanrooms are not sterile (i.e., free of uncontrolled microbes)[1] and more attention is given to airborne particles. Particle levels are usually tested using a particle counter.

Some cleanrooms are kept at a positive pressure so that if there are any leaks, air leaks out of the chamber instead of unfiltered air coming in.

Some cleanroom HVAC systems control the humidity to low levels, such that extra equipment ("ionizers") are necessary to prevent electrostatic discharge (ESD) problems.

Low-level cleanrooms may only require special shoes, ones with completely smooth soles that do not track in dust or dirt. However, shoe bottoms must not create slipping hazards (safety always takes precedence). Entering a cleanroom usually requires wearing a cleanroom suit.[2]

In other cleanrooms, in which the standards of air contamination are less rigorous, the entrance to the cleanroom may not have an air shower. There is an anteroom (known as a "gray room"), in which the special suits must be put on, but then a person can walk in directly to the room (as seen in the photograph on the right).

Some manufacturing facilities do not use fully classified cleanrooms, but use some cleanroom practices together to maintain their cleanliness requirements.[3][4]

Air flow principles

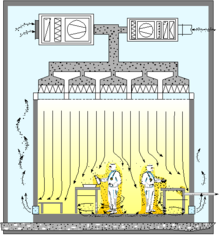

Air flow pattern for "Laminar Flow Cleanroom"

Air flow pattern for "Laminar Flow Cleanroom"

Cleanrooms maintain particulate-free air through the use of either HEPA or ULPA filters employing laminar or turbulent air flow principles. Laminar, or unidirectional, air flow systems direct filtered air downward in a constant stream towards filters located on walls near the cleanroom floor or through raised perforated floor panels to be recirculated. Laminar air flow systems are typically employed across 80 percent of a cleanroom ceiling to maintain constant air processing. Stainless steel or other non-shed materials are used to construct laminar air flow filters and hoods to prevent excess particles entering the air. Turbulent, or non-unidirectional, air flow uses both laminar air flow hoods and non-specific velocity filters to keep air in a cleanroom in constant motion, although not all in the same direction. The rough air seeks to trap particles that may be in the air and drive them towards the floor, where they enter filters and leave the cleanroom environment.[5]

Cleanroom classifications

Cleanrooms are classified according to the number and size of particles permitted per volume of air. Large numbers like "class 100" or "class 1000" refer to FED-STD-209E, and denote the number of particles of size 0.5 µm or larger permitted per cubic foot of air. The standard also allows interpolation, so it is possible to describe e.g. "class 2000".

A discrete-particle-counting, light-scattering instrument is used to determine the concentration of airborne particles, equal to and larger than the specified sizes, at designated sampling locations.

Small numbers refer to ISO 14644-1 standards, which specify the decimal logarithm of the number of particles 0.1 µm or larger permitted per cubic metre of air. So, for example, an ISO class 5 cleanroom has at most 105 = 100,000 particles per m³.

Both FS 209E and ISO 14644-1 assume log-log relationships between particle size and particle concentration. For that reason, there is no such thing as zero particle concentration. The table locations without entries are non-applicable combinations of particle sizes and cleanliness classes, and should not be read as zero.

Because 1 m³ is approximately 35 ft³, the two standards are mostly equivalent when measuring 0.5 µm particles, although the testing standards differ. Ordinary room air is approximately class 1,000,000 or ISO 9.[6]

US FED STD 209E cleanroom standards

Class maximum particles/ft³ ISO

equivalent≥0.1 µm ≥0.2 µm ≥0.3 µm ≥0.5 µm ≥5 µm 1 35 7 3 1 ISO 3 10 350 75 30 10 ISO 4 100 750 300 100 ISO 5 1,000 1,000 7 ISO 6 10,000 10,000 70 ISO 7 100,000 100,000 700 ISO 8 US FED STD 209E was officially cancelled by the General Services Administration of the US Department of Commerce November 29, 2001,[7][8] but is still widely used.

ISO 14644-1 cleanroom standards

Class maximum particles/m³ FED STD 209E

equivalent≥0.1 µm ≥0.2 µm ≥0.3 µm ≥0.5 µm ≥1 µm ≥5 µm ISO 1 10 2 ISO 2 100 24 10 4 ISO 3 1,000 237 102 35 8 Class 1 ISO 4 10,000 2,370 1,020 352 83 Class 10 ISO 5 100,000 23,700 10,200 3,520 832 29 Class 100 ISO 6 1,000,000 237,000 102,000 35,200 8,320 293 Class 1000 ISO 7 352,000 83,200 2,930 Class 10,000 ISO 8 3,520,000 832,000 29,300 Class 100,000 ISO 9 35,200,000 8,320,000 293,000 Room air BS 5295 cleanroom standards

maximum particles/m³ Class ≥0.5 µm ≥1 µm ≥5 µm ≥10 µm ≥25 µm Class 1 3,000 0 0 0 Class 2 300,000 2,000 30 Class 3 1,000,000 20,000 4,000 300 Class 4 200,000 40,000 4,000 BS 5295 Class 1 also requires that the greatest particle present in any sample does not exceed 5 μm.[9]

GMP EU classification[10]

Class maximum particles/m³ under equipped conditions under equipped conditions under working conditions under working conditions 0.5 µm 5 µm 0.5 µm 5 µm Class A 3500 0 3500 0 Class B 3500 0 350000 2000 Class C 350000 2000 3500000 20000 Class D 3500000 20000 n/a n/a See also

- Air Quality Index

- Cleanroom (pharmaceutical)

- Cleanroom safety

- Clean room worker

- Data recovery lab

- Secure environment

- Sterile Quality Index

- ISO 14644

- ISO 14698

- Contamination control

- Pneumatic filter

- Semiconductor device fabrication

- Sterile room

References

- ^ [1]

- ^ Cleanroom Clothing

- ^ Your Cleanroom Supplier :: Hutchins & Hutchins, Inc

- ^ Cleanroom Forum

- ^ Cleanroom Air Flow Principles

- ^ Cleanroom Classification / Particle Count / FS209E / ISO TC209 /

- ^ Cancellation of FED-STD-209E - Institute of Environmental Sciences and Technology

- ^ http://www.wbdg.org/ccb/FEDMIL/notices.pdf, page 148

- ^ Market Venture Philippines Inc. web site

- ^ Pharmaceutical equipment and technologies

External links

Categories:- Rooms

- Semiconductor device fabrication

- Filters

Wikimedia Foundation. 2010.