- Cold stamping

-

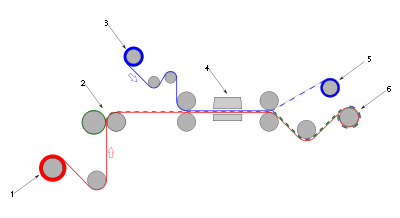

Cold stamping, also known as press working[1], is a manufacturing operation where thermoplastics in sheet form are cold-formed using methods similar to metals[2]. A precut thermoplastic sheet, either reinforced or unreinforced, is softened by heating the sheet to a temperature particular to the plastic in use. The heated sheet is then shaped by stamping using a press[3]. Fiberglass-reinforced thermoplastic sheets are formed using metal stamping presses after the sheets are preheated to about 200°C (392°F)[2].

References

- ^ HS Bawa. "Manufacturing Processes -- II". Tata McGraw-Hill, 2004. ISBN 0070583722. ISBN 9780070583726. http://books.google.com/

- ^ a b Erik Lokensgard, Terry L Richardson. "Industrial plastics: Theory and applications". Cengage Learning, 2003. ISBN 1401804691. ISBN 9781401804695. http://books.google.com/

- ^ stamping. Marlene G Rosato. "Concise encyclopedia of plastics". Springer, 2001. ISBN 0792384962. ISBN 9780792384960. http://books.google.com/

Categories:

Wikimedia Foundation. 2010.