- Material selection

-

Material selection is a step in the process of designing any physical object. In the context of product design, the main goal of material selection is to minimize cost while meeting product performance goals.[1] Systematic selection of the best material for a given application begins with properties and costs of candidate materials. For example, a thermal blanket must have poor thermal conductivity in order to minimize heat transfer for a given temperature difference.

Systematic selection for applications requiring multiple criteria is more complex. For example, a rod which should be stiff and light requires a material with high Young's modulus and low density. If the rod will be pulled in tension, the specific modulus, or modulus divided by density E / ρ, will determine the best material. But because a plate's bending stiffness scales as its thickness cubed, the best material for a stiff and light plate is determined by the cube root of stiffness divided density

![\sqrt[3]{E}/\rho](3/573197035beba3273080fc76c637f25a.png) .

.Contents

Ashby plots

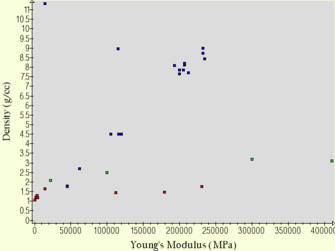

An Ashby plot, named for Michael Ashby of Cambridge University, is a scatter plot which displays two or more properties of many materials or classes of materials.[2] An Ashby plot useful for the example of the stiff, light part discussed above would have Young's modulus on one axis and density on the other axis, with one data point on the graph for each candidate material. On such a plot, it is easy to find not only the material with the highest stiffness, or that with the lowest density, but that with the best ratio E / ρ. Using a log scale on both axes facilitates selection of the material with the best plate stiffness

![\sqrt[3]{E}/\rho](3/573197035beba3273080fc76c637f25a.png) .

.The first Ashby plot on the right shows density and Young's modulus, without a log scale. Metals are represented by blue squares, ceramics by green, and polymers by red. It was generated by the Material Grapher.[3]

The second plot shows the same materials attributes for a database of approx 100 materials. Materials families (polymers, foams, metals, etc.) are identified by the larger colored bubbles. The image is created using Prof Mike Ashby's own CES Selector software and data from Granta Design.[4]

Cost issues

Cost of materials plays a very significant role in their selection. The most straightforward way to weight cost against properties is to develop a monetary metric for properties of parts. For example, life cycle assessment can show that the net present value of reducing the weight of a car by 1 kg averages around $5, so material substitution which reduces the weight of a car can cost up to $5 per kilogram of weight reduction more than the original material.[citation needed] However, the geography- and time-dependence of energy, maintenance and other operating costs, and variation in discount rates and usage patterns (distance driven per year in this example) between individuals, means that there is no single correct number for this. For commercial aircraft, this number is closer to $450/kg, and for spacecraft, launch costs around $20,000/kg dominate selection decisions.[citation needed]

Thus as energy prices have increased and technology has improved, automobiles have substituted increasing amounts of light weight magnesium and aluminium alloys for steel, aircraft are substituting carbon fiber reinforced plastic and titanium alloys for aluminium, and satellites have long been made out of exotic composite materials.

Of course, cost per kg is not the only important factor in material selection. An important concept is 'cost per unit of function'. For example, if the key design objective was the stiffness of a plate of the material, as described in the introductory paragraph above, then the designer would need a material with the optimal combination of density, Young's modulus, and price. Optimizing complex combinations of technical and price properties is a hard process to achieve manually, so rational material selection software is an important tool.

References

- ^ George E. Dieter (1997). "Overview of the Materials Selection Process", ASM Handbook Volume 20: Materials Selection and Design.

- ^ Ashby, Michael (1999). Materials Selection in Mechanical Design (3rd edition ed.). Burlington, Massachusetts: Butterworth-Heinemann. ISBN 0-7506-4357-9.

- ^ "Material Grapher". Materials Digital Library Pathway MatDL.org. http://orbis.kent.edu/matdl/matml/select.php.

- ^ "Granta Design". Granta Design. http://www.grantadesign.com.

External links

Categories:- Materials science

- Product development

- Design

Wikimedia Foundation. 2010.