- Hoist (device)

-

This article is about Hoist (device). For other uses, see Hoist (disambiguation).

A hoist is a device used for lifting or lowering a load by means of a drum or lift-wheel around which rope or chain wraps. It may be manually operated, electrically or pneumatically driven and may use chain, fiber or wire rope as its lifting medium. The load is attached to the hoist by means of a lifting hook.

Contents

Types of Hoist

The basic hoist has two important characteristics to define it: Lifting medium and power type. The lifting medium is either wire rope, wrapped around a drum, or load-chain, raised by a pulley with a special profile to engage the chain. The power can be provided by different means. Common means are hydraulics, electrical and air driven motors. Both the wire rope hoist and chain hoist have been in common use since the 1800s. however; Mass production of an electric hoist did not start until the early 1900's and was first adapted by Germany. A hoist can be built as one integral-package unit, designed for cost-effective purchasing and moderate use, or it can be built as a built-up custom unit, designed for durability and performance. The built-up hoist will be much more expensive, but will also be easier to repair and more durable. Package units where once regarded as being designed for light to moderate usage, but since the 60's this has changed. Built-up units are designed for heavy to severe service, but over the years that market has decreased in size since the advent of the more durable packaged hoist. A machine shop or fabricating shop will use an integral-package hoist, while a Steel Mill or NASA would use a built-up unit to meet durability, performance, and repairability requirements. NASA has also seen a change in the use of package hoists. The NASA Astronaut training pool for example utilizes cranes with packaged hoists.

Wire Rope Hoist or Chain Hoist

Builder's hoist, with small petrol engine

Builder's hoist, with small petrol engine

More commonly used hoist in today’s worldwide market is an electrically powered hoist. These are either the chain type or the wire rope type.

Now many hoists are package hoists, built as one unit in a single housing, generally designed for ten-year life, but the life calculation is based on an industry standard when calculating actual life. See the Hoists Manufacturers Institute site[1] for true life calculation which is based on load and hours used. In today's modern world for the North American market there are a few governing bodies for the industry. The Overhead Alliance is a group that represents Crane Manufacturers Association of America (CMAA), Hoist Manufacturers Institute (HMI), and Monorail Manufacturers Association (MMA). These product counsels of the Material Handling Industry of America have joined forces to create promotional materials to raise the awareness of the benefits to overhead lifting. The members of this group are marketing representatives of the member companies.

Common small portable hoists are of two main types, the chain hoist or chain block and the wire rope or cable type. Chain hoists may have a lever to actuate the hoist or have a loop of operating chain that one pulls through the block (known traditionally as a chain fall) which then activates the block to take up the main lifting chain.

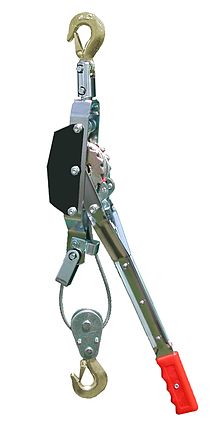

A hand powered hoist with a ratchet wheel is known as a "ratchet lever hoist" or, colloquially, a "Come-A-Long". The original hoist of this type was developed by Abraham Maasdam of Deep Creek, Colorado about 1919, and later commercialized by his son, Felber Maasdam, about 1946. It has been copied by many manufacturers in recent decades. A similar heavy duty unit with a combination chain and cable became available in 1935 that was used by railroads, but lacked the success of the cable only type units. [2]

Ratchet lever hoists have the advantage that they can usually be operated in any orientation, for pulling, lifting or binding. Chain block type hoists are usually suitable only for vertical lifting.

For a given rated load wire rope is lighter in weight per unit length but overall length is limited by the drum diameter that the cable must be wound onto. The lift chain of a chain hoist is far larger than the liftwheel over which chain may function. Therefore, a high-performance chain hoist may be of significantly smaller physical size than a wire rope hoist rated at the same working load.Both systems fail over time through fatigue fractures if operated repeatedly at loads more than a small percentage of their tensile breaking strength. Hoists are often designed with internal clutches to limit operating loads below this threshold. Within such limits wire rope rusts from the inside outward while chain links are markedly reduced in cross section through wear on the inner surfaces. Regular lubrication of both tensile systems is recommended to reduce frequency of replacement. High speed lifting, greater than about 60 feet per minute (18.3 m/min), requires wire rope wound on a drum, because chain over a pocket wheel generates fatigue-inducing resonance for long lifts.

The unloaded wire rope of small hand powered hoists often exhibits a snarled "set", making the use of a chain hoist in this application less frustrating, but heavier. In addition, if the wire in a wire hoist fails, it can whip and cause injury, while a chain will simply break.

Construction hoists

Also known as a Man-Lift, Buckhoist, temporary elevator, builder hoist, passenger hoist or construction elevator, this type of hoist is commonly used on large scale construction projects, such as high-rise buildings or major hospitals. There are many other uses for the construction elevator. Many other industries use the buckhoist for full time operations. The purpose being to carry personnel, materials, and equipment quickly between the ground and higher floors, or between floors in the middle of a structure.

The construction hoist is made up of either one or two cars (cages) which travel vertically along stacked mast tower sections. The mast sections are attached to the structure or building every 25 feet (7.62 m) for added stability. For precisely controlled travel along the mast sections, modern construction hoists use a motorized rack-and-pinion system that climbs the mast sections at various speeds.

While hoists have been predominantly produced in Europe and the United States, China is emerging as a manufacturer of hoists to be used in Asia.

In the United States and abroad, General Contractors and various other industrial markets rent or lease hoists for a specific projects. Rental or leasing companies provide erection, dismantling, and repair services to their hoists to provide General Contractors with turnkey services. Also the rental and leasing companies can provide parts and service for the elevators that are under contract.

Mine hoists

Main article: Hoist (mining) A water-powered mine hoist used for raising ore from De re metallica.

A water-powered mine hoist used for raising ore from De re metallica.

In underground mining a hoist or winder[3] is used to raise and lower conveyances within the mine shaft. Human, animal and water power were used to power the mine hoists documented in Agricola's De Re Metallica, published in 1556. Stationary steam engines were commonly used to power mine hoists through the 19th century and into the 20th, as at the Quincy Mine, where a 4-cylinder cross-compound corliss engine was used.[4] Modern hoists are powered using electric motors, historically with direct current drives utilizing solid-state converters (thyristors), however modern large hoists use alternating current drives that are variable frequency controlled.[3] There are three principal types of hoists used in mining applications, Drum Hoists, Friction (or Kope) hoists and Blair multi-rope hoists.

See also

References

- ^ http://www.mhia.org/industrygroups/hmi/technicalpapers

- ^ "New Jack Enables One Man To Pull Heavy Loads" Popular Science, May 1935, article & photo bottom of page 39

- ^ a b De la Vergne, Jack (2003). Hard Rock Miner's Handbook. Tempe/North Bay: McIntosh Engineering. pp. 114–124. ISBN 0-968006-1-6. http://www.mcintoshengineering.com/HardRockMinersHandbook/tabid/76/Default.aspx.

- ^ Quincy No. 2 Mine Hoist (1920) National Historic Engineering Landmark brochure, The American Society of Mechanical Engineers, 1984.

External links

Categories:- Lifting equipment

- Actuators

Wikimedia Foundation. 2010.