- Trucker's hitch

-

trucker's hitch

Trucker's hitch with alpine butterfly loopNames trucker's hitch, lorry driver's hitch,[1] harvester's hitch,[1] hay knot,[2] sheepshank cinch,[2] trucker's dolly,[3] wagoner's hitch,[3] power cinch[4] Category Hitch Related versatackle knot, sheepshank Typical use Making a rope very tight, such as to secure an object to a vehicle Caveat Can produce excessive wear on rope, especially if tied repeatedly in the same spot ABoK #1514, #2124, #2125, #2126 The trucker's hitch is a compound knot commonly used for securing loads on trucks or trailers. This general arrangement, using loops and turns in the rope itself to form a crude block and tackle, has long been used to tension lines and is known by multiple names.[1][2] Knot author Geoffrey Budworth claims the knot can be traced back to the days when carters and hawkers used horse-drawn conveyances to move their wares from place to place.[5]

Contents

Variations

The portion of the trucker's hitch which differs in the following variations is the method used to form the loop which the working end slides through to produce the mechanical advantage. The different methods of forming the loop affect the ease and speed of tying and releasing and the stability of the final product.

The variations are presented in order of increasing stability.

Sheepshank style loop

This version of the knot uses a sheepshank-like construction, in this kind of application also known as a bell ringer's knot, to form the loop. It is quicker to make than a fixed loop, but is less dependable.[1][6] It is avoided in critical applications (such as securing a load on a truck) as it can fall apart under too little load or too much load, and can capsize if not dressed properly.[3] However, this knot may be made secure by adding a Half Hitch by using the top bight of the Sheepshank. This form of the trucker's hitch is least likely to jam, coming apart easily once tension is released. Different sources show slight variations in the way the sheepshank portion is formed and dressed.

Slipped overhand loop

The loop formed in this version is a simple Slipped Overhand Loop or a variation using multiple turns of rope to form the eye of the loop. If extra loops are used to form the eye it tends to ease untying. In order to prevent the closing of the loop under load, the loop must be formed by the working end of the rope (which will later pass through the loop). If the standing end goes through the loop, it will close under load.

Fixed loop

The most reliable common variation uses a fixed loop, such as an alpine butterfly loop, artillery loop, figure-eight loop, or another of many suitable loop knots.[3][7] If a fixed loop is used repeatedly for tying the trucker's hitch in the same portion of rope, excessive wear or other damage may be suffered by the portion of the loop which working end slides against.[1]

-

Trucker's hitch using alpine butterfly loop, finished with a slipped double half hitch.

Finishing the hitch

In tightening the trucker's hitch, tension can be effectively increased by repeatedly pulling sideways while preventing the tail end from slipping through the loop, and then cinching the knot tighter as the sideways force is released. This is called "sweating a line".[8]

Once tight, the trucker's hitch is often secured with a half hitch, usually slipped for easy releasing and to avoid the necessity of access to the end of the rope, though a more secure finish, such as two half hitches, may be called for. Under large loads, the finishing half hitch can jam, especially if it is not slipped; the difficulty of releasing it can be compounded by the fact that the knot is typically still under tension when it is untied.

Mechanical advantage and friction

All common variations of the trucker's hitch use a loop in the standing part of the rope and the anchor point as make-shift pulleys in order to theoretically obtain a 3 to 1 mechanical advantage while pulling on the working end.

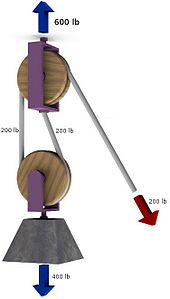

There is sometimes confusion about how much theoretical mechanical advantage is provided by the trucker's hitch. If the trucker's hitch were to be used as in the pulley diagram at right, to lift a weight off the floor, the theoretical mechanical advantage would be only 2:1. However in the common use of the trucker's hitch, a static hook, ring, or rail, serves as the lower pulley, and the rope across the top of the load is the portion being tensioned. Thus, the standing part of the rope is represented by the top anchor point in the diagram, and the theoretical ratio is indeed 3:1 when the working end is tensioned. That is, in a frictionless system, every unit of force exerted on the working end would produce 3 units in the standing part of the rope over the load. In the typical use of the trucker's hitch, where it is used to tighten a rope over a load, when the end is secured to the loop of the Truckers hitch and let go, the tension in the two segments of rope around the ring will rise 50%, unless the rope slackens when it is being tied off, in which case the tension may drop to any value or even zero if enough slack is allowed. But when the trucker's hitch is used as in the diagram, after tying off, the load on the attachment point above the top pulley will drop to 400 lb and the tension in the two lines going to the lower pulley will not change.

Theoretical considerations aside, in real world use the mechanical advantage of the trucker's hitch is significantly less than the ideal case due to the effects of friction. Friction has been reported to reduce the mechanical advantage from 3 to 1, down to less than 1 to 1 in many cases. One advantage of the friction within the trucker's hitch, compared to a hypothetical pulley-based system, is that it allows the hitch to be held taut with less force while the working end is secured.

See also

- Load securing

- List of knots

References

- ^ a b c d e Des Pawson (2002), Pocket Guide to Knots & Splices, Edison, NJ: Chartwell Books, Inc., p. 142

- ^ a b c Cyrus Lawrence Day (1986), The Art of Knotting and Splicing (4th ed.), Annapolis: Naval Institute Press, p. 116

- ^ a b c d Gordon Perry (2006), Knots, North Vancouver: Quantum Publishing, pp. 134–135

- ^ Cliff Jacobson (1977), Wilderness Canoeing & Camping, Dutton, p. 118, "...there seems to be no widely accepted name for this hitch, so I took the liberty of naming it the power-cinch"

- ^ Geoffrey Budworth (1999), The Ultimate Encyclopedia of Knots, London: Hermes House, pp. 224–225

- ^ Ashley, Clifford W. (1944), The Ashley Book of Knots, New York: Doubleday, p. 344, "A quicker but less dependable lashing is based on the Bell Ringer's Knot #1148."

- ^ Ashley, p. 271

- ^ John Mellor (1996), Handling Troubles Afloat, Dobbs Ferry, NY: Sheridan House, pp. 195–196

External links

Categories:- Hitch knots

Wikimedia Foundation. 2010.