- Delta robot

-

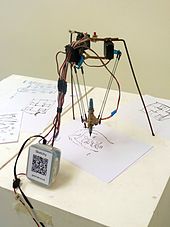

Sketchy, a portrait-drawing delta robot[1]

Sketchy, a portrait-drawing delta robot[1]

A delta robot is a type of parallel robot. It consists of three arms connected to universal joints at the base. The key design feature is the use of parallelograms in the arms, which maintains the orientation of the end effector. By contrast a Stewart platform can change the orientation of its end effector.

The delta robots have popular usage in picking and packaging in factories because they can be quite fast, some executing up to 300 picks per minute.[2]

Contents

History

The Delta robot (a parallel arm robot) was invented in the early 1980s by Reymond Clavel at the École Polytechnique Fédérale de Lausanne (EPFL, Switzerland).[3] The purpose of this new type of robot was to manipulate light and small objects at a very high speed, an industrial need at that time. In 1987, the company Demaurex purchased a license for the Delta robot and started the production of Delta robots for the packaging industry. In 1991 Reymond Clavel presents his doctoral thesis 'Conception d'un robot parallèle rapide à 4 degrés de liberté' and receives the golden robot award in 1999 for his work and development of the Delta robot. Also in 1999, ABB Flexible Automation starts selling its Delta robot, the FlexPicker. By the end of 1999 the Delta robots are also sold by Sigpack Systems.

Design

The Delta robot is a parallel robot, i.e. it consists of multiple kinematic chains interconnecting the base with the platform. The robot can also be seen as a spatial generalisation of a four-bar linkage. It has four degrees of freedom[citation needed]: three translational and one rotational[citation needed]. The key concept of the Delta robot is the use of parallelograms. These parallelograms restrict the movement of the end platform to pure translation (only movement in the X, Y or Z direction). The robot's base is mounted above the workspace. All the actuators are located in this base. From the base, three middle jointed arms extend. The arms are made of lightweight composite material. The ends of the three arms are connected to a small triangular platform. Actuation of the input links will move the triangular platform in the X, Y or Z direction. Actuation can be done with linear or rotational actuators. From the base, a fourth leg extends to the middle of the triangular platform to give the end effector a fourth, rotational degree of freedom.

Because the actuators are all located in the base, and the arms can be made of a light composite material the moving parts of the Delta robot have a small inertia. This allows for very high accelerations. Accelerations can be up to 30 g and speeds of 10 m/s can be reached.[citation needed]

Applications

Industries that take advantage of the high speed of the Delta robot are the packaging industry, medical and pharmaceutical industry. Other possible applications include assembly tasks or operation in a clean room for electronic components. The structure of the Delta robot can also be used to create haptic controllers[4], such as the Force Dimension omega.x, delta.x and sigma.x devices, or the Novint Falcon game controller.

References

- ^ "Sketchy, a home-constructed drawing robot". Jarkman. http://www.jarkman.co.uk/catalog/robots/sketchy.htm.

- ^ http://www.botjunkie.com/2009/11/03/adept-quattro-is-fastest-ever-for-the-moment/

- ^ US 4976582

- ^ Sunny Bains (8 August 2007). "Feeling virtual worlds". http://sunnybains.typepad.com/blog/2007/08/feeling-virtual.html.

- Clavel, R. (1991) Conception d'un robot parallèle rapide à 4 degrés de liberté. Ph.D. Thesis, EPFL, Lausanne, Switzerland

- Bonev, I. (2001) Delta Parallel Robot — the Story of Success, Online article available at http://www.parallemic.org/Reviews/Review002.html

External links

Categories:- Robot kinematics

- Industrial robots

- 1980s in robotics

Wikimedia Foundation. 2010.