- Deadweight tester

-

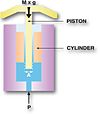

A dead weight tester apparatus uses known traceable weights to apply pressure to a fluid for checking the accuracy of readings from a pressure gauge. A dead weight tester (DWT) is a calibration standard method that uses a piston cylinder on which a load is placed to make an equilibrium with an applied pressure underneath the piston. Deadweight testers are so called primary standards which means that the pressure measured by a deadweight tester is defined through other quantities: length, mass and time. Typically deadweight testers are used in calibration laboratories to calibrate pressure transfer standards like electronic pressure measuring devices.

Contents

Formula

The formula on which the design of a DWT is based basically is expressed as follows :

p = F / A [Pa] where :

p : reference pressure [Pa] F : force applied on piston [N] A : effective area PCU [m2] To be able to do accurate measurements, this formula has to be refined.

Absolute pressure with vacuum reference

p= m.gl.

æ

è1-

ra rmö

ø+P.d.t

A(20,0).(1+(ap+ac).(t-20)).(1+pnom.lp)-(rN2-ra).gl.h+pvac gauge pressure

pe= m.gl.

æ

è1-

ra rmö

ø+P.d.t

A(20,0).(1+(ap+ac).(t-20)).(1+pnom.lp)-(rN2-ra).gl.h nomenclature

p absolute pressure at reference level [Pa] pe gauge pressure at reference level [Pa] m total true mass load [kg] gl local acceleration due to gravity [N/kg] ra ambient air density [kg/m3] rm average density mass load [kg/m3] P.d.t surface tension effect [N] rN2 density of pressure medium [kg/m3] h reference level offset DWT .. DUT [m] pvac vacuum residual pressure [Pa] A20,0 PCU effective area at p=0 and 20oC [m2] ap linear thermal expansion coefficient piston [oC-1] ac linear thermal expansion coefficient cylinder [oC-1] t temperature of PCU [oC] lp elastic deformation coefficient PCU [Pa-1] pnom nominal line pressure [Pa] pe gauge pressure applied to PCU [Pa] p absolute pressure applied to PCU [Pa] piston cylinder design

In general there are three different kind of DWT's divided by the medium which is measured and the lubricant which is used for its measuring element :

1. gas operated gas lubricated PCU's 2. gas operated oil lubricated PCU's 3. oil operated oil lubricated PCU's

All three systems have their own specific operational demands. Some points of attention :

gas - gas

Make sure that the PCU is clean. This is a very important issue as the PCU's operation is sensitive to contamination. Also when connecting a DUT, make sure that the DUT does not introduce contamination in the measuring system.

gas - oil

Lubricant of the PCU 'leaks' in the gas-circuit of the DWT. For this reason there is a small reservoir incorporated in the system. Before commencing a calibration it is a good practice to purge this reservoir. If the reservoir is full, oil will be introduced in critical tubing and will cause an uncontrollable oil-head.

oil - oil

When connecting an oil filled DUT on an oil DWT make sure that the DUT oil will not contaminate the DWT oil. If in doubt. Incorporate a small volume between DUT and DWT and manipulate pressure in such a matter that th oil flow is directed to the DUT.

See also

- Blaise Pascal

- Calibration

- Force gauge

- Piezometer

- Pressure measurement

- Pressure sensor

- Vacuum engineering

External links

Categories:- Measuring instruments

Wikimedia Foundation. 2010.