- Orbital welding

-

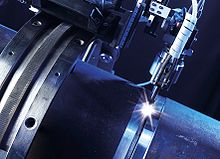

Orbital welding is a specialised area of welding whereby the arc is rotated mechanically through 360° (180 degrees in double up welding) around a static workpiece, an object such as a pipe, in a continuous process.

Contents

History

The orbital welding process was invented over 50 years ago.

Equipment

The main components of every orbital welding system are the power source and controller, the welding head, water cooler and, where required, a wire feed mechanism. There are a large number of factors that can have an influence on the welding result. These aspects include the arc length, magnitude and pulse frequency of the welding current, welding speed, inert shielding gas, parent material, filler material, weld preparation, and thermal conductivity. Ultimately, a high quality weld is achieved through detailed knowledge of how to precisely adjust all these parameters for each individual welding task.

Application

The welding process

It is very difficult to achieve the highest standards of quality and safety using manual welding. This is due to certain welding positions, overhead and down-hand welds for example, often leading to faulty welds due to restricted access the user has in these welding positions. In order to have complete control over the weld pool, a perfect balance must be maintained between gravitational force and surface tension at every position of the torch. By using mechanised variants of the technique, certain parts of the welding process are handled by mechanical components. Note that a welder will always be monitoring and controlling the process. In an ideal situation, all welding parameters would be fully programmed before welding is started. In practice, however, the presence of variable constraints means that it is often necessary for the welder to make corrective interventions. With automated welding, the computer-controlled welding process runs completely independently, without the need for any intervention from the operator.

Materials

Orbital welding has almost always exclusively been carried out by the Tungsten Inert Gas (TIG) technique using non-consumable electrodes, with additional cold-wire feed where necessary. Many different types of metal can be welded; high-strength, high-temperature and corrosion-resistant steels, unalloyed and low-alloyed carbon steels, nickel alloys, titanium, copper, aluminium and associated alloys. Carried out in an inert atmosphere, this controlled technique produces results that are extremely clean, have low particle counts and are free from unwanted spatter. This enables the highest demands to be met regarding the mechanical and optical properties of a weld seam.

Tube diameters

Due to the precision of orbital TIG welding, even the smallest standard tube diameters from 1.6 millimetres can be processed. On a larger scale, pipes with diameters up to 170mm and walls up to 3.5mm thick can be joined using closed chamber weld heads. These weld heads allow the torch to be positioned very precisely and ensure that the pipe is held securely. The inert gas atmosphere in the closed chamber prevents heat from tinting, even with the most sensitive of materials. For tube diameters between 8 and 275mm, it is possible to use more manageable open welding heads. A flexible hose system is used to supply the welding head with power, inert gas, cooling water and filler wire where required. The need for filler wire during the welding process depends on the type of welding task; thicker tube walls and difficult-to-control parent materials require the use of additional material, whereas thin-walled tubes can be welded without extra wire. In order to create high quality weld seams it is essential that tube ends are carefully prepared with the edges of the workpieces being free of scale and impurities. For thinner-walled tubes up to medium diameters, a simple right-angled saw cut is often sufficient. For thicker tube walls it is necessary to prepare the edges more carefully, for example using a U-groove cross-section.

Business sectors and markets

Owing to its ability to realise high purity results, orbital welding found its place in the production of clean-room components for the semiconductor industry. Its application has now expanded to the construction of pipework and equipment for diverse industries like food processing, pharmaceuticals, chemical engineering, automotive engineering, biotechnology, shipbuilding and aerospace. Automated orbital TIG welding is also used in the construction of power stations, (thermal power plants). The construction materials used must be able to withstand the enormous mechanical loads produced by the high pressures and temperatures created by the media carried in the tubes. Notches, pores and inclusions in the weld seams must be avoided at all costs, as these create weak points that can lead to subsequent the formation of cracks. These in turn can have serious consequences in terms of component failure. This means that tubes are often made from nickel-based materials with walls up to 200mm thick. One manufacturer has developed an orbital narrow gap welding system with hot-wire feed specifically for this purpose, which uses running gear that moves on a guide ring fixed around the tube. This new variant has created a lot of interest in the sector, with the worldwide boom in power station construction fueling the never-ending search for increasingly productive manufacturing methods using new types of high-temperature steels.

Conclusion

Along with the current methods of using TIG cold and hot wire welding, there has also been steady progress in the development of MIG/MAG/FCAW welding which allows a whole range of new applications. Orbital welding can provide reliable welding of reproducible quality using wide-ranging techniques and differing types of technique. This can be performed to a high standard even when using unusual materials, thick walls, small tube diameters and even within a difficult working environment.

References

- Krüger, Jürgen; Schnee, Dieter (2007). Rundum sicher. bbr 3 (2007): 40-42.

Categories:

Wikimedia Foundation. 2010.